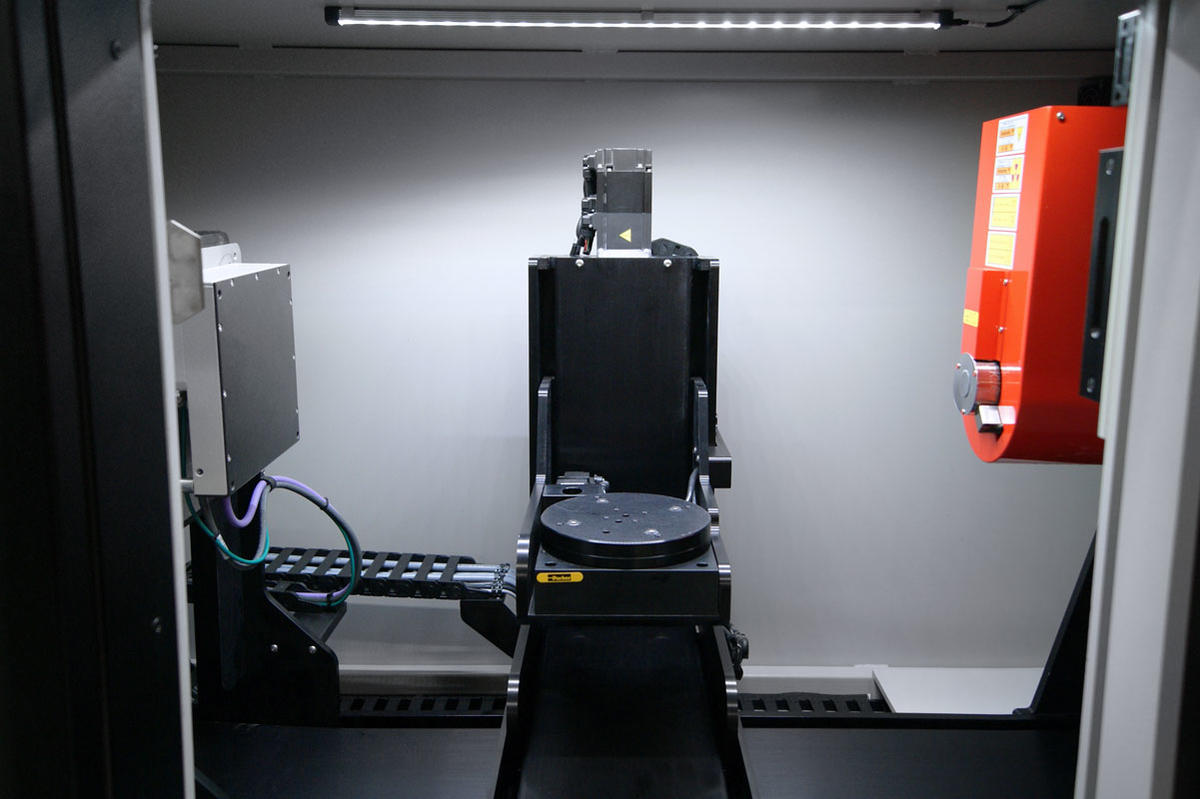

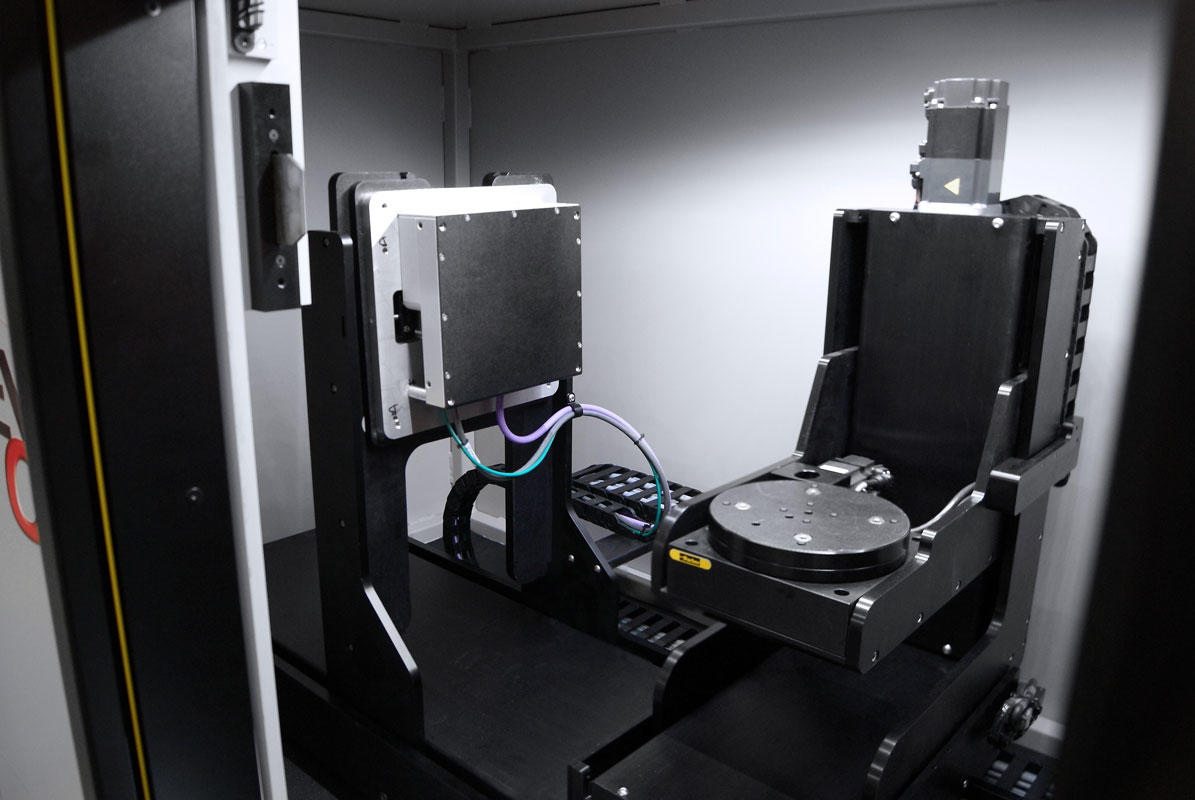

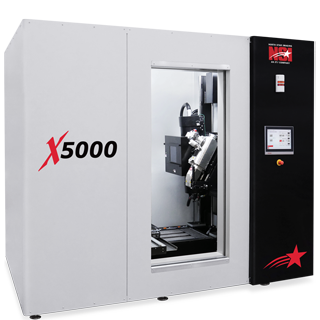

X25 Industrial CT Scanning System

Specifications

- Ideal for submicron X-ray and CT applications

- DICONDE compliant

- Integrated Process Controls

- Advanced Imaging Modalities

- Integrated efX Software Suite

- Integrated Motion Control

- Available with our automated RobotiX add-on

- Comprehensive acquisition, processing and archival program with user-friendly interface

- High performance image processing and measurement functions

- DICONDE compliant

- Non-proprietary multiple image format output/input.

- Automated program functions for fast analysis

- Multiple window interface for display of raw image, processed image, density data, etc.

- Computed Tomography acquisition module

- Optional 3D Computed Tomography calibration, reconstruction and visualization

- Optional 4D Computed Tomography

- Available with SubpiX,VorteX, and Ring Reduction

- Voltage Range: 10 kV – 160 kV

- Minimum Focal Spot Size: ~900 nm

- X-ray Tube Types:

- Microfocus – Reflection

- Microfocus – Transmission

- Digital X-ray Detector Types: Flat Panel (DDA)

- Grade Options: Premium, Superior (ASTM)

- Pixel Pitch: 127 μm

- Maximum Detector Size: 7.68 x 9.6 in [19.5 x 24.4 cm]

- Maximum Sample Weight: 25 lb [11 kg]

- Part Travel:

- Horizontal: 6 in [15 cm]

- Vertical: 9 in [22 cm]

- Source to Detector: 32 in [86 cm]

- Rotation: 360° Continuous

- Nominal Part Envelope: 9 x 6 in [22 x 15 cm]

- Maximum Focal Distance: 37 in [94 cm]

- Part Manipulation Control:

- All drives variable speed joystick controlled

- Each axis is independently controlled

- Control-X: Programmable CNC controlled automated scanning with automatic image processing and archiving capabilities

- External Dimensions:

- Width: 73 in [186 cm]

- Depth: 37.1 in [94 cm]

- Height: 71 in [180 cm]

- Weight: 3,500 lb [1,590 kg]

- Cabinet Features: Cable access port with cover, interior lighting, powered sliding access door(s), leaded glass viewing window, safety light curtains

- Steel/lead/steel construction

- Meets or exceeds 21 CFR 1020.40 and EN 61010-2-091 2012

- Touch screen operation

- Vibration isolation system

- System includes one ergonomic desk and chair

X25 Industrial CT Scanning System

Applications

- Failure Analysis

- Assembly Verification

- Reverse Engineering

- Density Analysis

- Finite Element Analysis

- Void and Porosity Analysis

- 2D and 3D Metrology

- Internal and External Measurements

- Product Quality Compliance

- Research and Development (R&D)

- 3D CAD comparisons

- Weld and Braze Quality Analysis

- In Situ Monitoring

- Additive Manufacturing System Qualification

X25 Industrial CT Scanning System

Downloads

X25 Industrial CT Scanning System

Compact & Efficient

The X25 is well suited for small to medium sized objects. It offers the same features as our larger systems while being able to fit through a standard size door. North Star Imaging’s team of experts will help you select the best system configuration for your application.Have a question? Want a demo?

X-Ray Training

Looking for technical training programs?

Service & Support

- Preventative Maintenance

- 12 Point Inspections

- On-site Repair & Service

- Relocation Support