efX Software Version 2.3

North Star Imaging is proud to announce our latest efX software release, version 2.3. Many of the features included in efX 2.3 were based on your feedback.

Virtual Center of Rotation

Virtual Center of Rotation (VCOR) allows you to keep the region of interest on your part centered on the detector without the hassle of manually finding the perfect center of the turntable. No more struggling with fixtures, repeatedly opening and shutting the system door to adjust the part, or hanging large parts off the edge of the turntable. With VCOR, you get to choose what area of your scan should be the center and your X-ray system will ensure that the table rotates around the point you selected. This can also be used to take several scans of a single part such as one low magnification overview scan and then multiple high magnification scans, all without ever opening the door or re-fixturing your part.

efX-Sim

efX-Sim uses a sophisticated X-ray algorithm that simulates how a polychromatic X-ray beam interacts with parts, alloys, and even multiple materials at once. This algorithm is GPU-accelerated, allowing the simulation to be run interactively. This means that any change to the system or parts being simulated will update the final detector image immediately, without the significant delay associated with non-interactive simulations.

efX-Sim can be configured as a digital twin to our standard systems, which enables technique development without occupying or interrupting a physical system. Thanks to its speed, you can quickly test if a part’s material properties, size, and orientation are compatible with specific X-ray systems. Additionally, you can test what imaging procedures and fixturing setups are required to examine critical areas, verify achieved resolution, and capture the details and defects you need. Techniques and fixtures that are prototyped on a digital twin can be used on the original system as real, physical techniques and fixtures. Created fixtures can even be exported to CAD software to develop 3d printable physical fixtures.

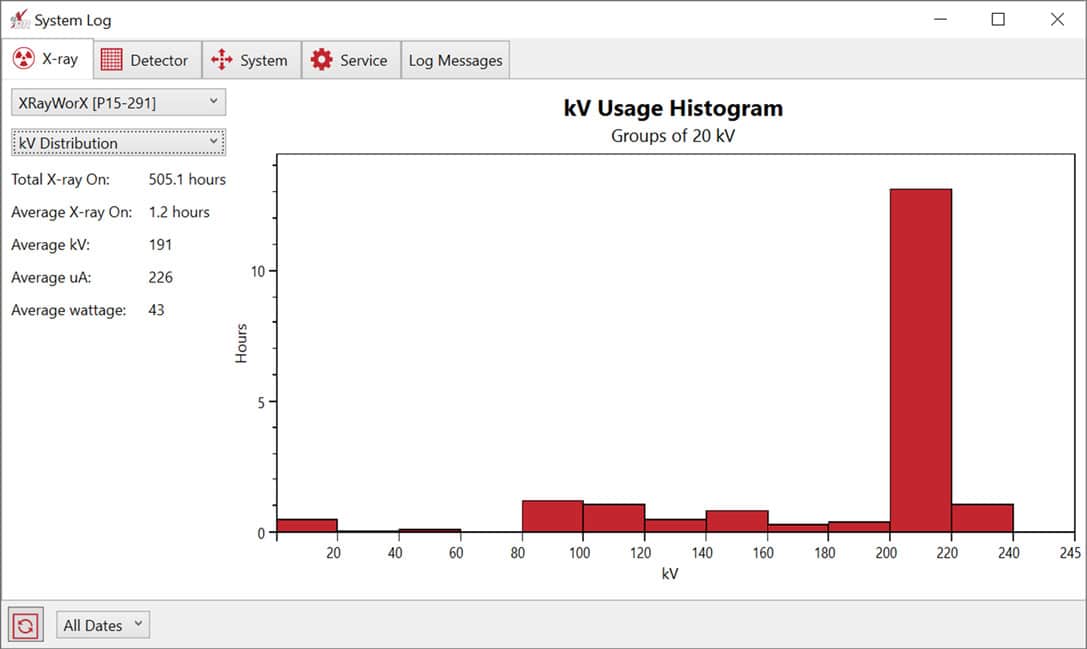

System Log

We know that the most important aspects of managing an X-ray system are ensuring the system stays operational and maximizing the system’s utilization. Until now, system managers have had to rely on their own diligence and note taking in order to keep their systems performing at the highest level possible. Now you have a powerful resource to help them manage your system. The system log gives you access to information about the system’s X-ray source, detector, utilization and service records. These tools help to ensure that your system is healthy and running efficiently.

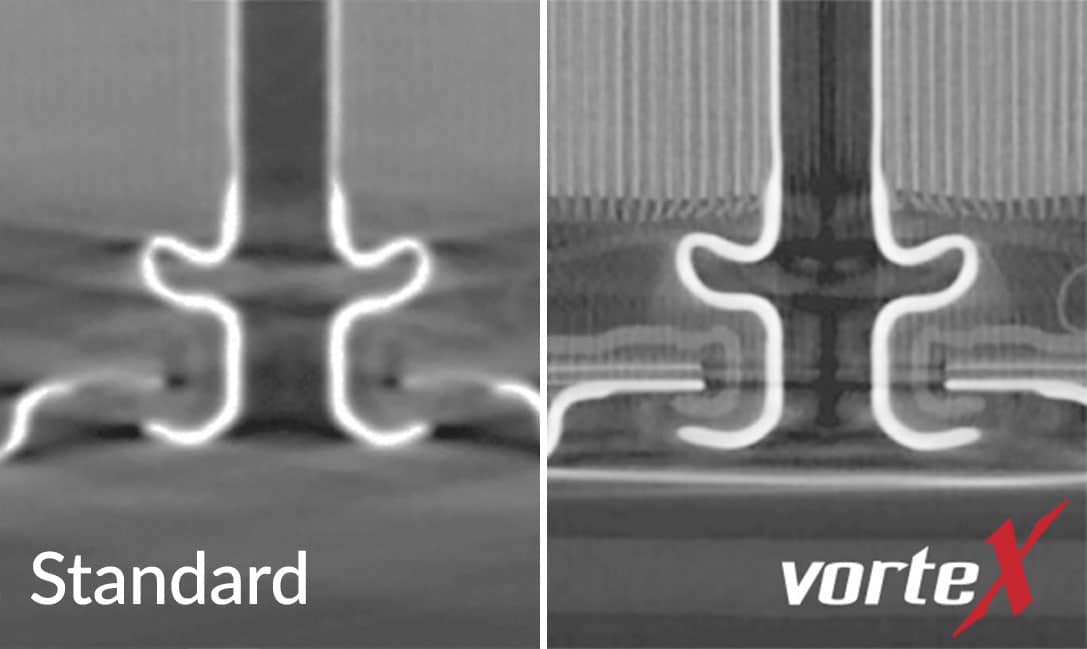

VorteX Enhancements

The VorteX acquisition interface has been simplified to automatically recommend scan details which result in a high-quality reconstruction. For a given magnification, we now recommend a maximum helical pitch to ensure an artifact-free reconstruction. Additionally, the number of scan projections is now more closely aligned with the number used to eliminate under-sampling in a circular CT scan. The improved VorteX interface allows you to easily adjust parameters to get a clear reconstruction of a feature on your part without cone beam artifacts, all in less time.

Additional Enhancements

- Motion Control Interface

- Grouping and ordering axes

- Motion Program Editor

- Apply or update any aspect of system (view ppt, source, detector, motion)

- Unit precision (display) configurable in application settings

- Copy paste of view ppts between instances of efX

- 2D: View or Clip plane

- 3D: CT window (includes position and orientation of clip planes)

- Process geometry in efX-DR at any time

- Radiograph caching in efX-CT to speed-up recon workflow

- Preview -> Adjust -> Recon share radios loaded into cache