efX-ADR Benefits

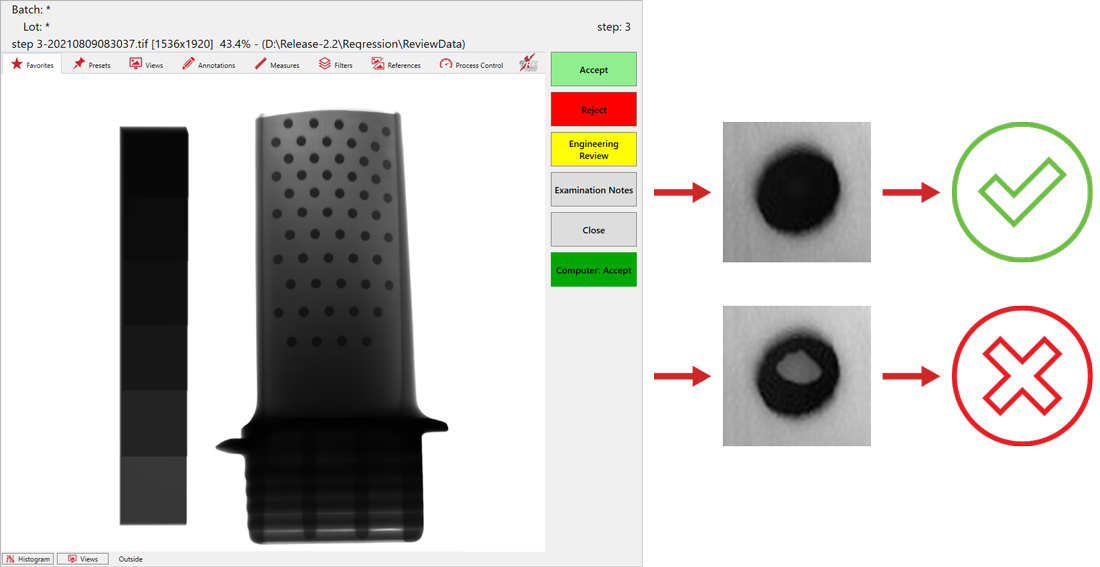

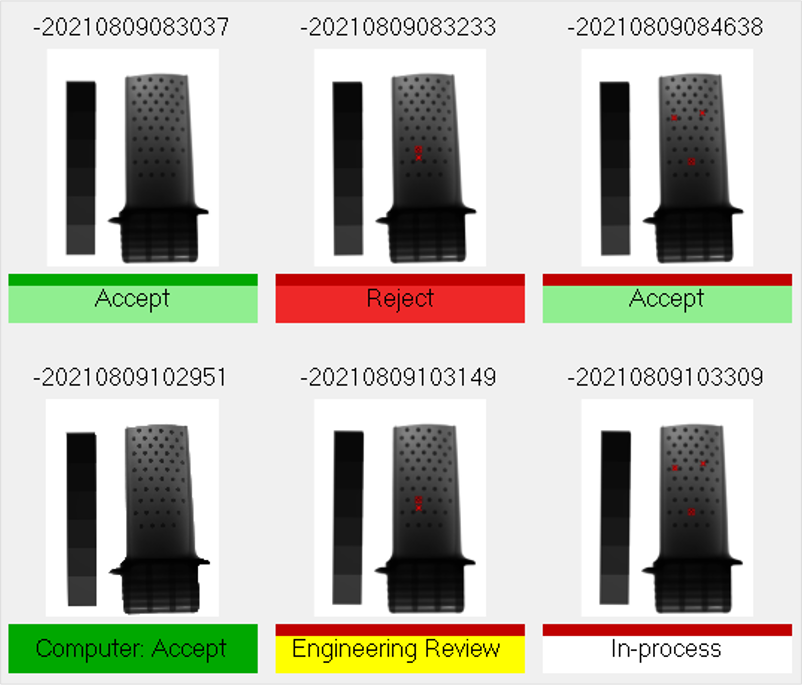

- Simple and intuitive user interface

- Customer configurable platform

- Fast image processing using GPU

- Seamless integration with the efX software suite

- Compatible & interoperable TIF, PNG & DCM image formats

- CT slice compatible

- Command line mode

- Folder monitoring

- Copy/Move/Delete input images

- Process control incorporation

efX-ADR Assisted Defect Recognition

More Information

Consider efX-ADR if you have:

- High volume products

- Products with inconsistent interpretation from personnel

- Monotonous parts to evaluate

- Missing component evaluations

- Component position evaluations

- Existing ADR solutions that are difficult to configure

- New parts have significant setup costs

Automatic Routines for Monitoring:

- Contrast, CNR, SNR, mean value variations

- Spatial resolution

- Min-max limitation boundaries

- Warning boundaries

- Stop work boundaries

- Regular interval evaluations of known defect standards

efX-ADR Assisted Defect Recognition

Downloads

efX-ADR Assisted Defect Recognition

Assisted Defect Recognition

efX-ADR offers a simple and intuitive user interface that easily integrates into production workflows for automatic processing. Users can inspect high volumes of products and increase the reliability of interpretations. Our software can help increase throughput, repeatability, and can reduce costs. Users can select from a wide range of defect-detection mechanisms to find what works best for their parts.Have a question? Want a demo?

X-Ray Training

Looking for technical training programs?

Service & Support

- 24/7 Support

- In-class and Online Training

- On-site Training & Service

- Software Updates

- Preventative Maintenance