RobotiX Part Loaders

RobotiX part loaders allow for automatic part loading and unloading for reduced cycle times and increased productivity. Our RobotiX solutions, when combined with our Assisted Defect Recognition software, can significantly automate the X-ray inspection process. This is more important than ever in a tight job market where human capital is at a premium. Set-up and operation of our RobotiX loaders are effortless through a simple interface that allows the operator to easily create new robotic motion programs. RobotiX motion programs are created through NSI’s efX-DR acquisition software. This feature allows the user to program the robot and configure the image acquisition parameters all through a single software interface. This means your operators don’t have to learn another software program, which saves your company valuable time and money.

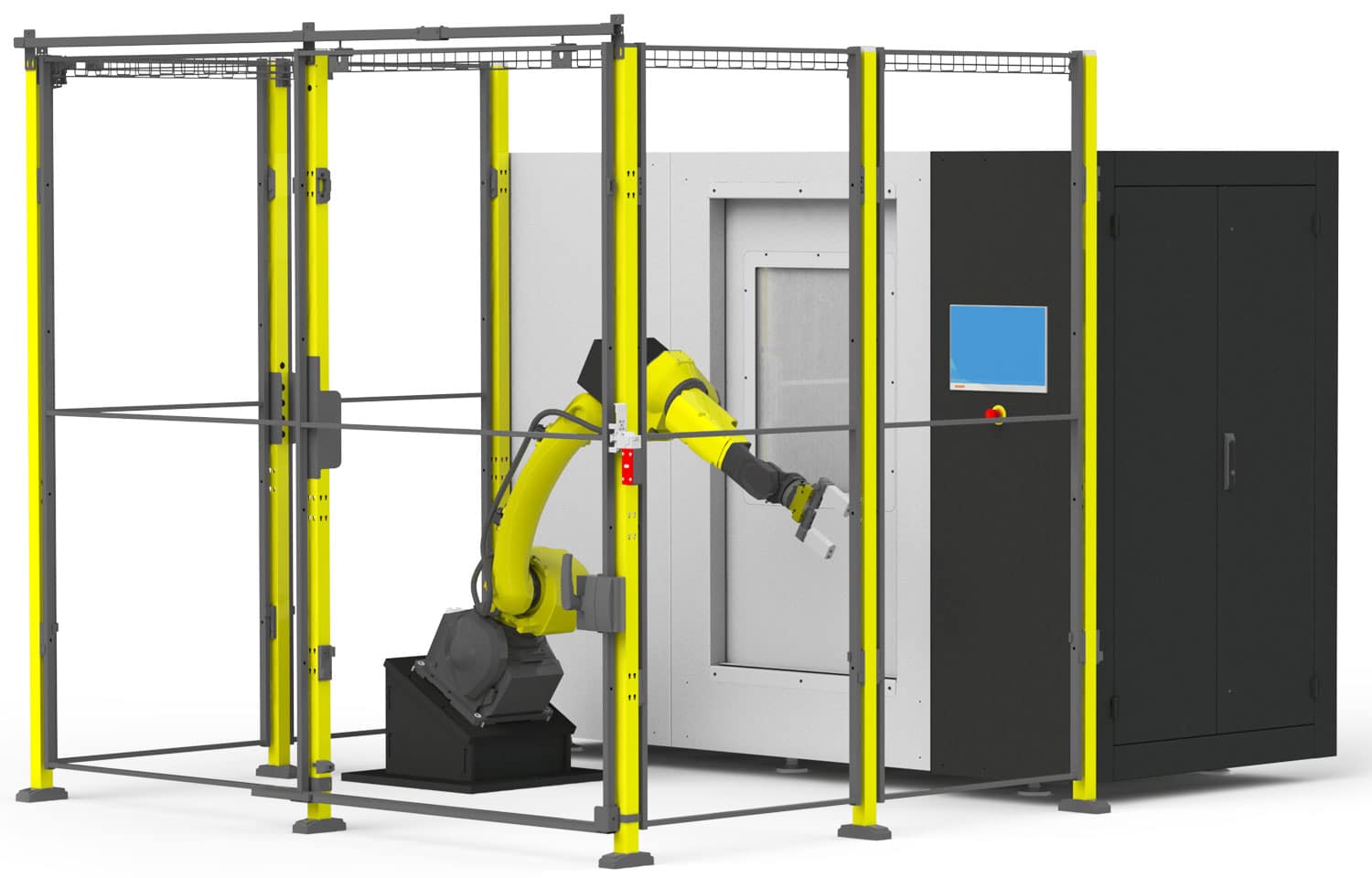

X3000 RobotiX Automated Industrial CT Scanning System

Specifications

- 6 Axis

- Reach & capacity dependent upon application

- Up to ±0.00079 in (± 0.02 mm) repeatability

- OSHA Compliant Safety Fence

- Fanuc M-10iD/12 robot

- 12 kg (26 lb) max payload

- 480 Vac +10%, 3 phase, 50/60 Hz, 30 Amp robot power requirement

- Robot mounted on angled pedestal

- Mount is anchored to floor

- Safety fence with sliding gate

- Supports electronic and pneumatic grippers

- X-ray Energies from 10 kV – 225 kV

- Minimum Focal Spot Size: ~900 nm

- Nominal Part Envelope: 19.5 x 24 in [50 x 61 cm]

- Maximum Focal Distance: 53 in [134.6 cm]

X3000 RobotiX Automated Industrial CT Scanning System

Downloads

X3000 RobotiX Automated Industrial CT Scanning System

Applications

- Failure Analysis

- Assembly Verification

- Reverse Engineering

- Density Analysis

- Finite Element Analysis

- Void and Porosity Analysis

- 2D and 3D Metrology

- Internal and External Measurements

- Product Quality Compliance

- Research and Development (R&D)

- 3D CAD comparisons

- Weld and Braze Quality Analysis

- In Situ Monitoring

- Additive Manufacturing System Qualification

X3000 RobotiX Automated Industrial CT Scanning System

Automated CT Scanning System

Robotic X-ray scanning systems make batch scanning and part loading & unloading effortless.Have a question? Want a demo?

X-Ray Training

Looking for technical training programs?

Service & Support

- Preventative Maintenance

- 12 Point Inspections

- On-site Repair & Service

- Relocation Support