High Energy CT Scanning Services

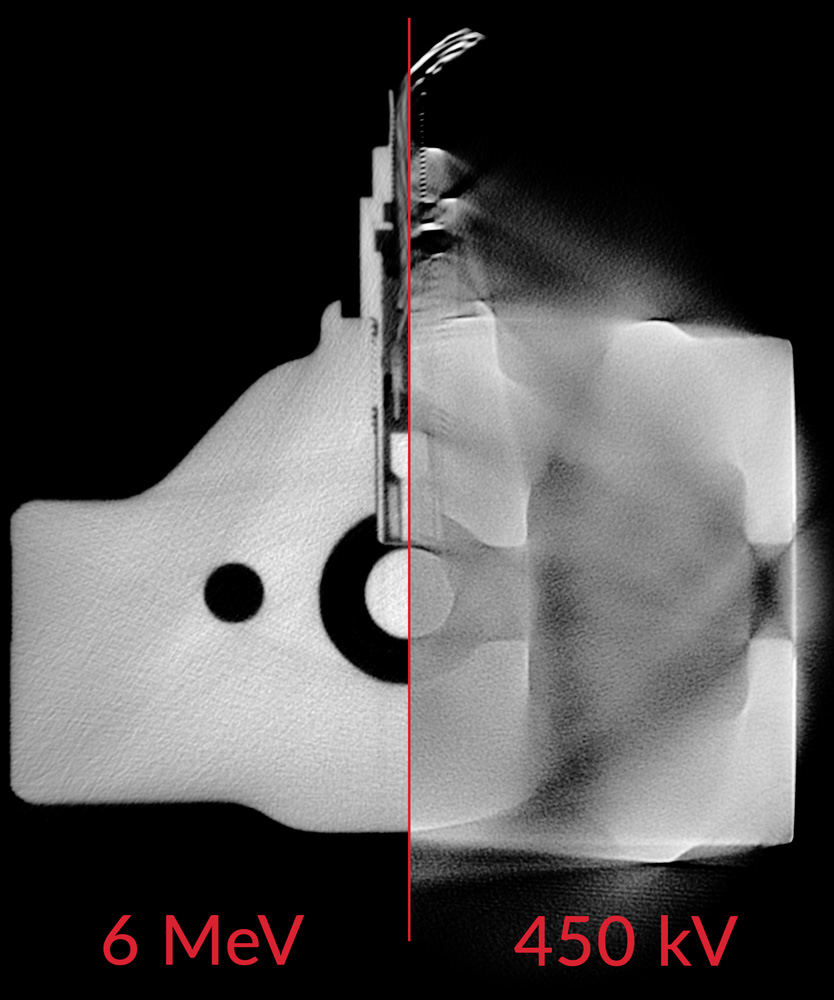

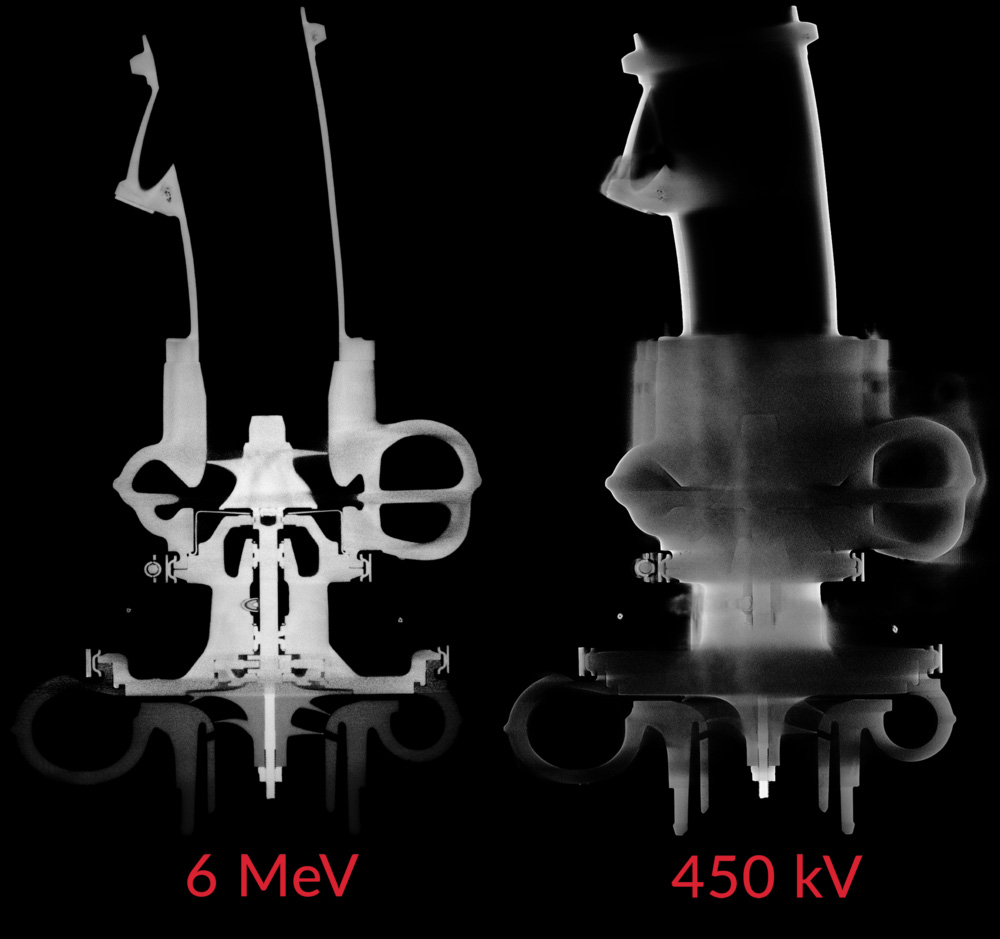

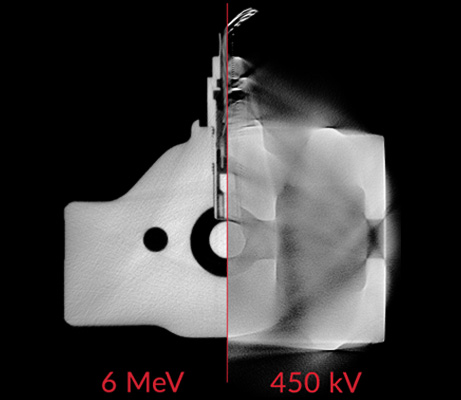

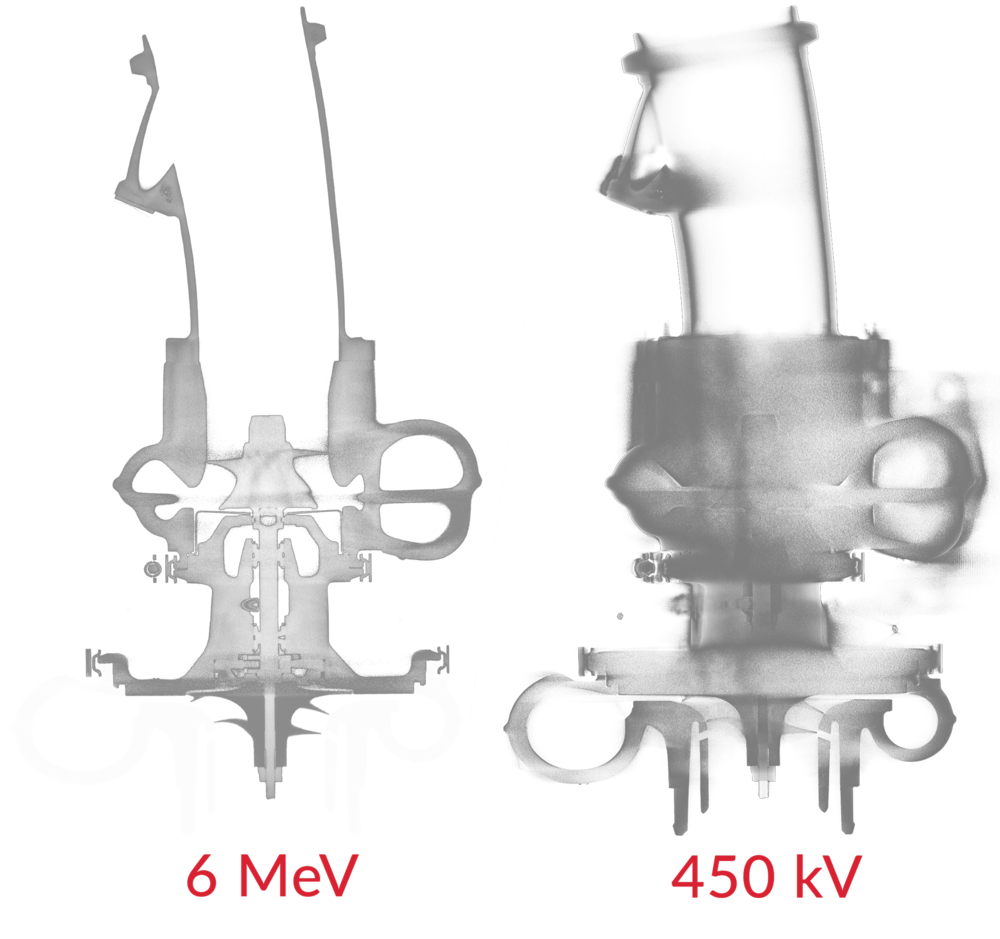

Remove the Questionable Interpretation - Better Penetration, Better Image Quality

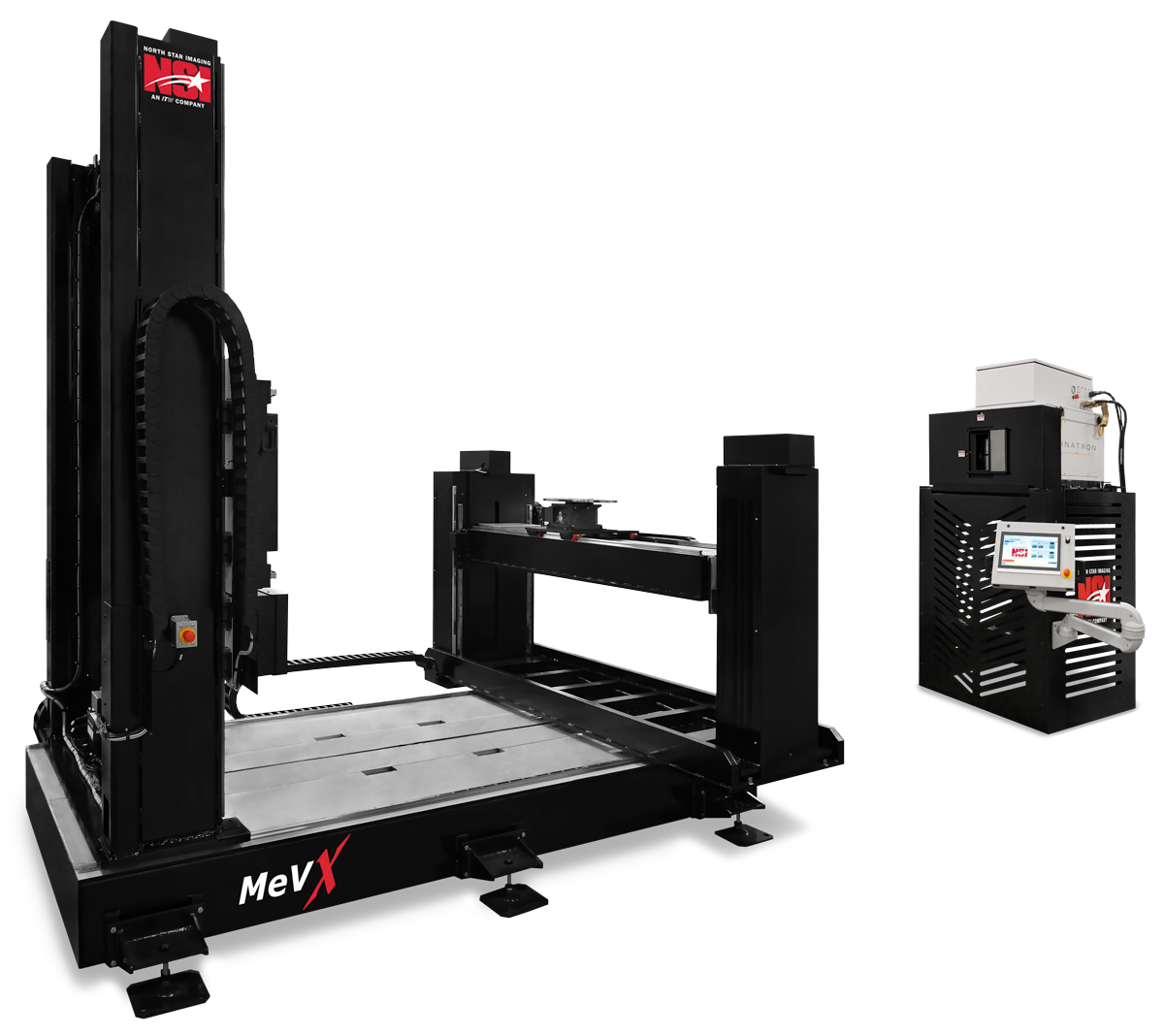

The MeVX CT System

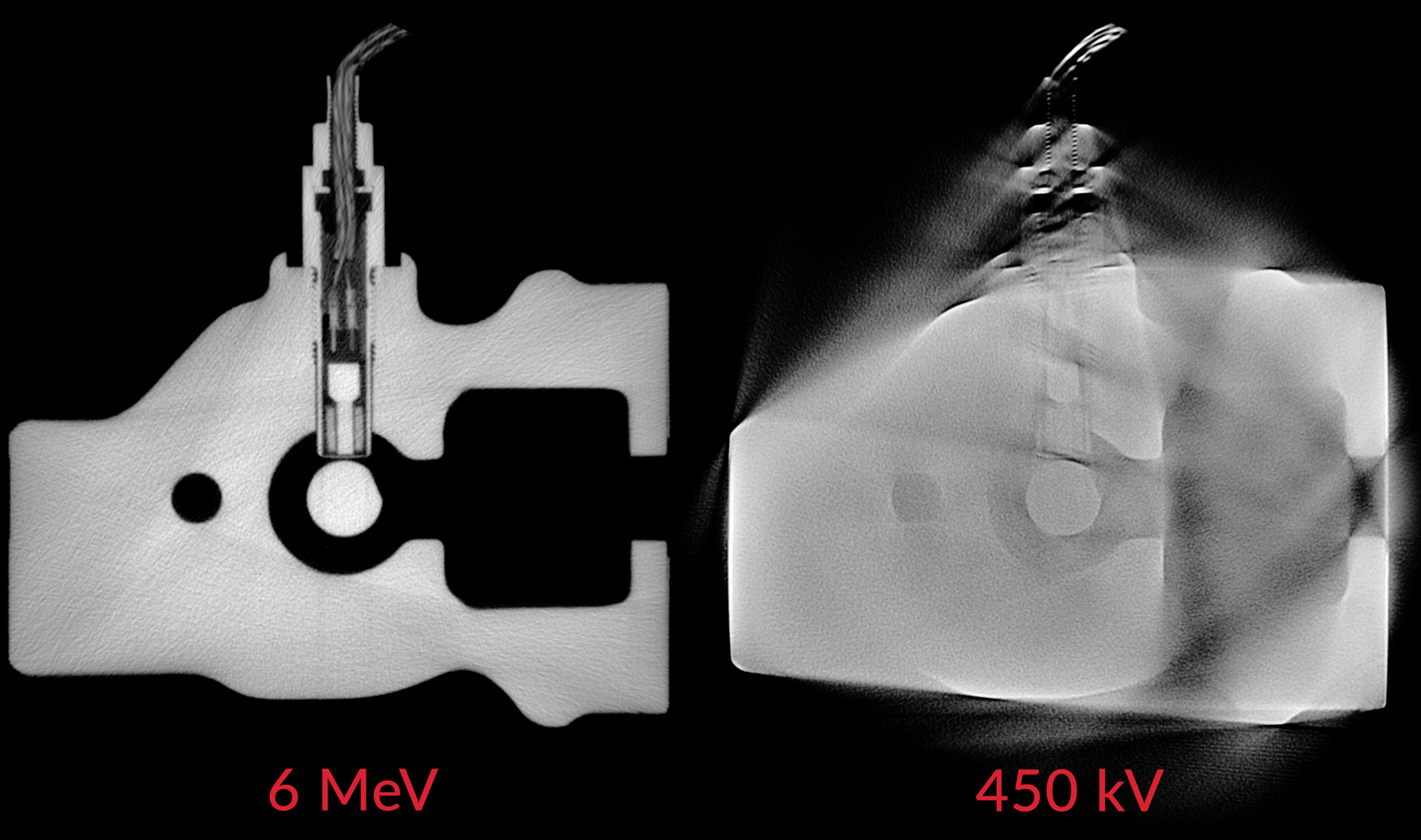

When you need to have the answers, what’s the true cost of not having enough energy? When inspecting large, dense, or thick materials; penetration can be difficult with energies of 450 kV and less. Noise, Scatter, and beam hardening artifacts negatively impact the image fidelity. The MeVX9 uses a 9 MeV linear accelerator (LINAC) to not only improve penetration but also image quality.

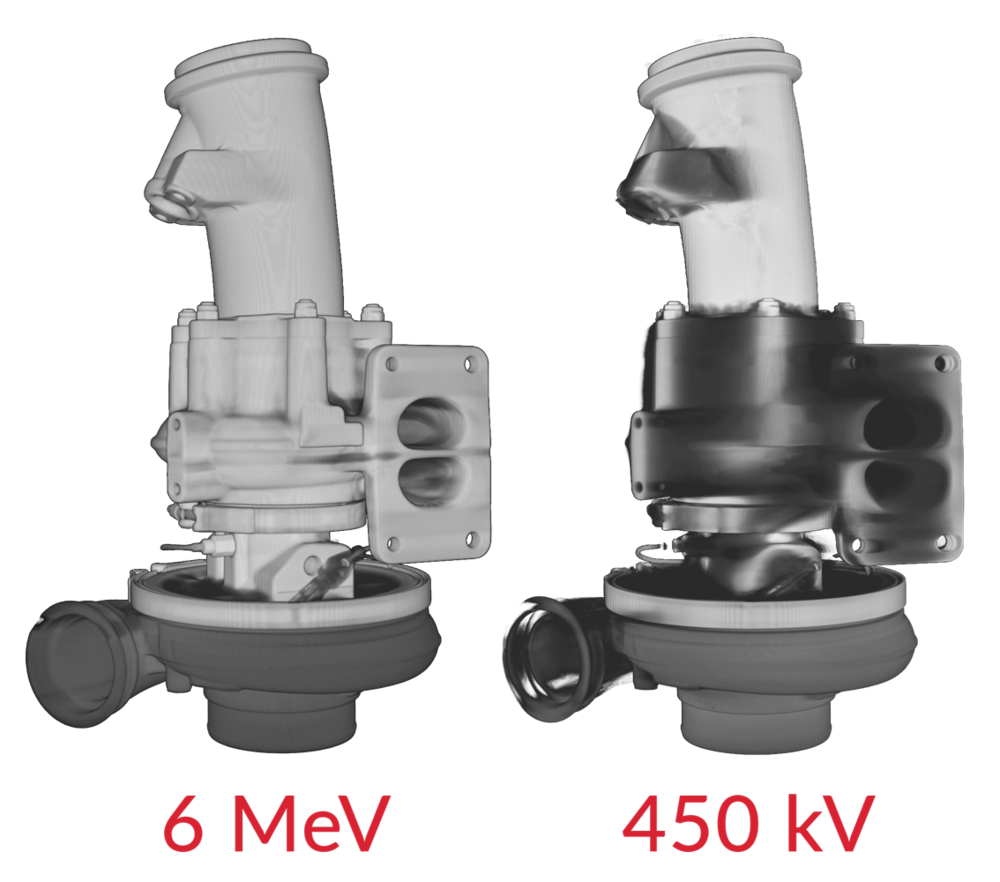

The Power of High Energy

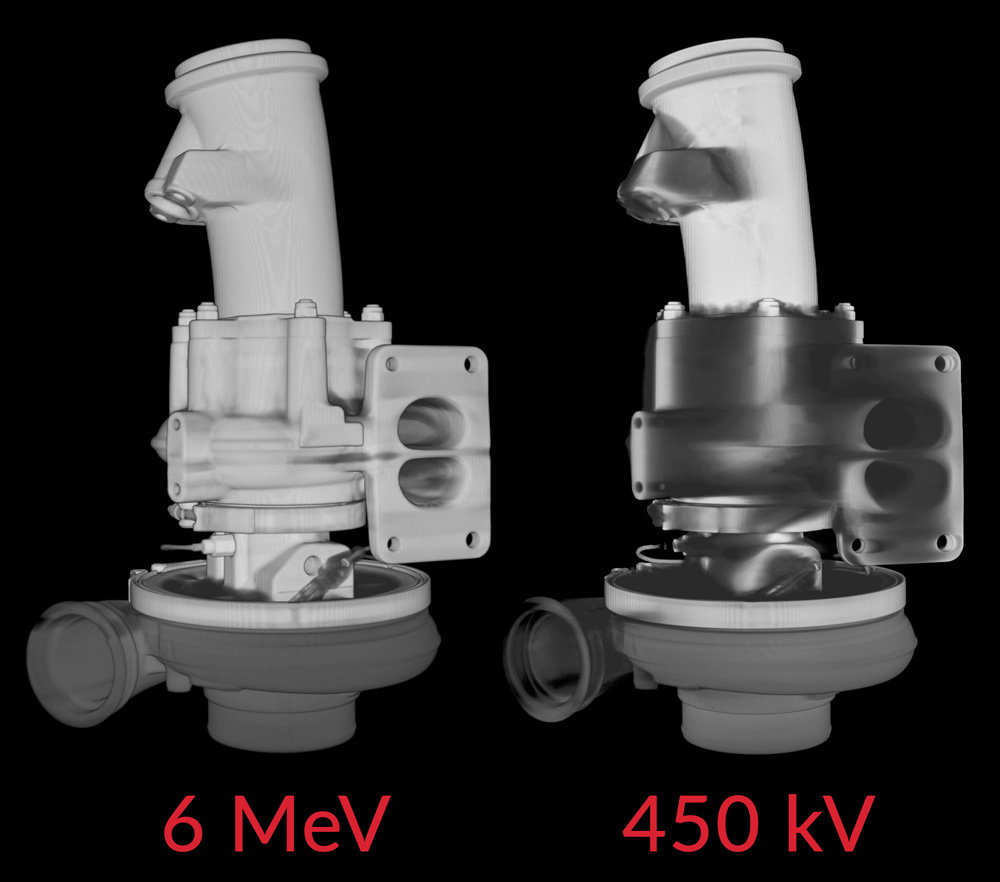

Nine million electron volts paired with proprietary scatter reduction technology; the MeVX9 has the power to get through your most difficult parts. As you can see with the Turbo Pump shown here, the added penetration significantly reduces artifacts. The reduction of these artifacts allows for better defect detection, geometrical representations of part features, and surfacing of volumetric data for nominal comparisons.

Remove the Questionable

Accurately represent your true data with our MeVX CT scanning capabilities. Remove the questionable interpretation and gain insight into better data. Increase measurement accuracy, feature clarity, and overall image quality with higher penetration power.

The Results Speak for Themselves

High energy industrial computed tomography scanning is great for:

- Failure Analysis

- Assembly Verification

- 2D and 3D Metrology

- Internal and External Measurements

- Research and Development (R&D)

- Product Quality Compliance

- Product Contamination

- Weld and Braze Quality Analysis

- Plastic Welding/Bonding Quality Verification

- Additive Manufacturing System Qualification

- Additive Manufacturing Process Monitoring

- Reverse Engineering

- Density Analysis

- In Situ Monitoring

- Advanced Material Analysis

- Museum Artifact Digitization

- Aluminum and Steel Castings Inspection

- Medical and Pharmaceutical Device Inspection

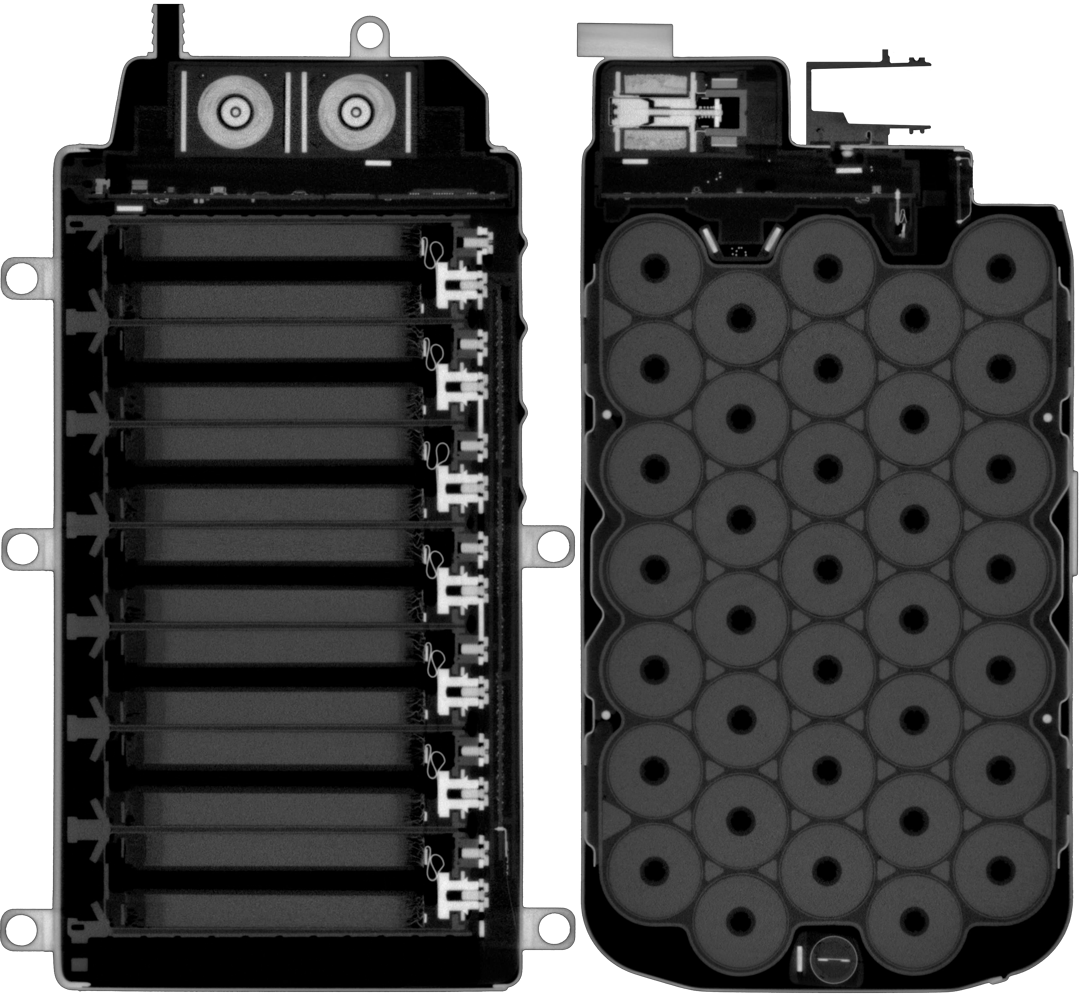

- Electronic Component Inspection

- Additive Manufacturing Product Inspection

- Food Products Inspection

- and much more

High Energy CT Process

Consult

Consult our application specialists to develop a plan of action.

Ship

Ship your product to any of our worldwide locations.

Scan/Data

Rotate, virtually cross section, and measure your part with our viewing software.

Results

Meet virtually or visit our facility to answer your questions.

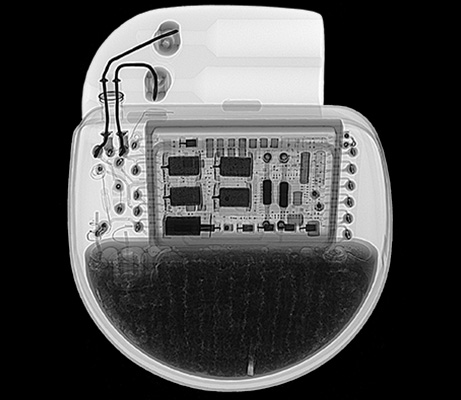

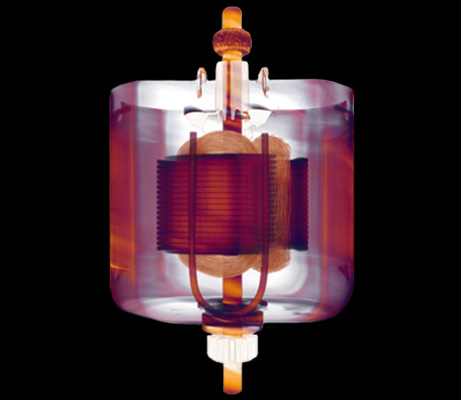

Gallery

Contact us for more information on High Energy CT Scanning Services

Please fill out the form on this page.

Other Scanning Services