How CT Can Answer Questions and Solve Problems

As you work to build the next great product within your industry, data-driven insights may be helpful during the design, testing, or troubleshooting phases of your project. Through 2D and 3D CT scanning, we can provide a detailed visual understanding of your product.

What is Computed Tomography (CT)?

Computed Tomography is an inspection technique that is entirely nondestructive, and it obtains information on just about any sized object – from microns to feet! Computed Tomography works by taking hundreds or thousands of 2D Digital Radiography projections around a 360 degree rotation of an object. Proprietary algorithms are then used to reconstruct the 2D projections into a 3D CT volume, which will allow you to view and slice the part at any angle.

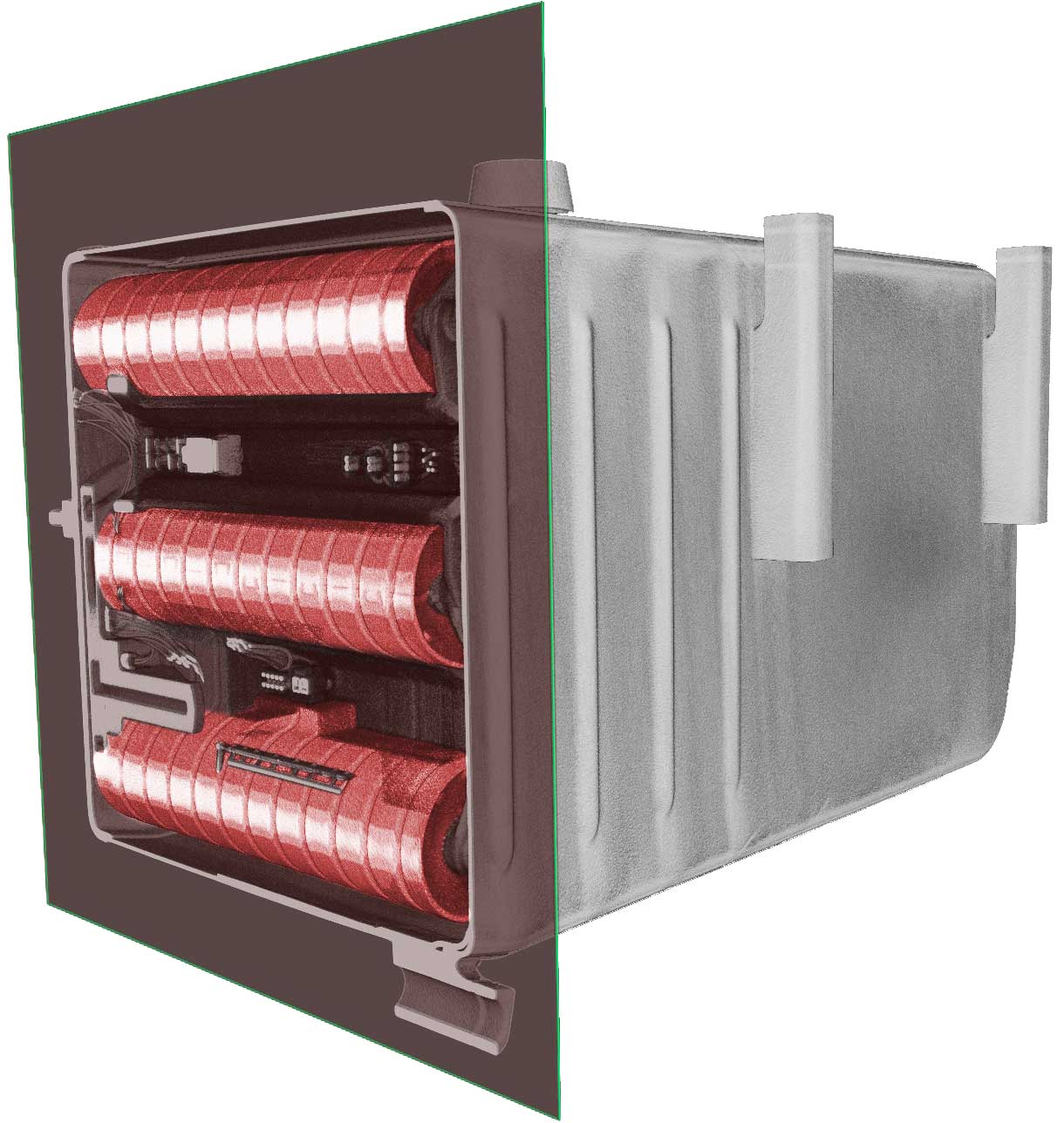

Sample X-Ray Inspection

Here’s a quick preview of how our technology inspected a cylinder head. It will give you a glimpse into the detail and variability of the visual data we can provide. This can then be used in many ways: product integrity verification, failure analysis, reverse engineering, and more.

How Can CT Be Used? How Can More + Better Data Help Answer Your Questions and Solve Problems?

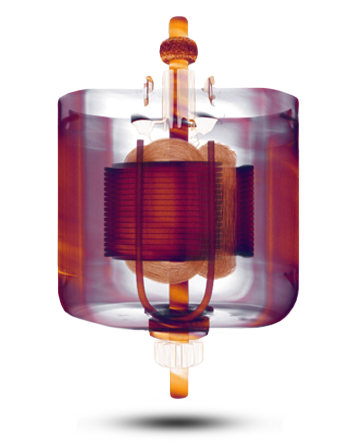

CT CAN SOLVE MYSTERIES

Determining the root cause of failure is a bit like solving a mystery; watch this small motor mystery to see how CT identified the failure point in this product. WATCH VIDEO ON BIG(GER) SCREEN.

CT CAN IDENTIFY UNKNOWN AND/OR NECESSARY DATA

Reverse engineering is not necessarily carried out to duplicate the part, but for analytical and testing purposes. It can be used for replicating worn parts, or converting physical models to digital ones. READ BLOG

CT CAN DETECT PART QUALITY AND INTEGRITY

Take a closer look at nondestructive testing and how that process uses CT scanning for early detection to gauge a parts quality and integrity. READ BLOG

Our Labs Are Never Too Far Away

Part and product scans happen at our Inspection Labs. In the United States, there are 3 of them. We welcome you for a visit if you’d like to see the technology in action; otherwise, find comfort in knowing your answers aren’t too far away. Learn more about our inspection process here.