2D Vs. 3D X-ray Scanning

X-ray imaging has proven indispensable in a wide range of industrial, medical, and research applications. Defined by their ability to penetrate otherwise opaque materials, X-rays allow analysts to glimpse the internal structures of objects relatively un-intrusively. The most easily recognizable form of X-ray imaging is the diagnostic tool used to identify bone damage or foreign objects within the body, yielding high-contrast, two-dimensional imagery. But X-ray scanning isn’t limited to two dimensions. This blog post will compare 2D to 3D X-ray scanning, with a focus on manufacturing applications.

What is 2D X-ray Scanning?

2D X-ray scanning is an imaging technique based on radiography that produces flat images in shades of gray, which only include horizontal and vertical dimensions. It requires a controlled environment and utilizes x-rays combined with a digital or analog detector to create images of an object that are displayed on a monitor.

2D scanning is widely used in dental and medical applications. However, it is also commonly used for inspections and quality control in the electronics, materials, and food industries. Because of its basis, 2D X-ray scanning is often referred to as 2D radiography.

What is 3D X-ray Scanning?

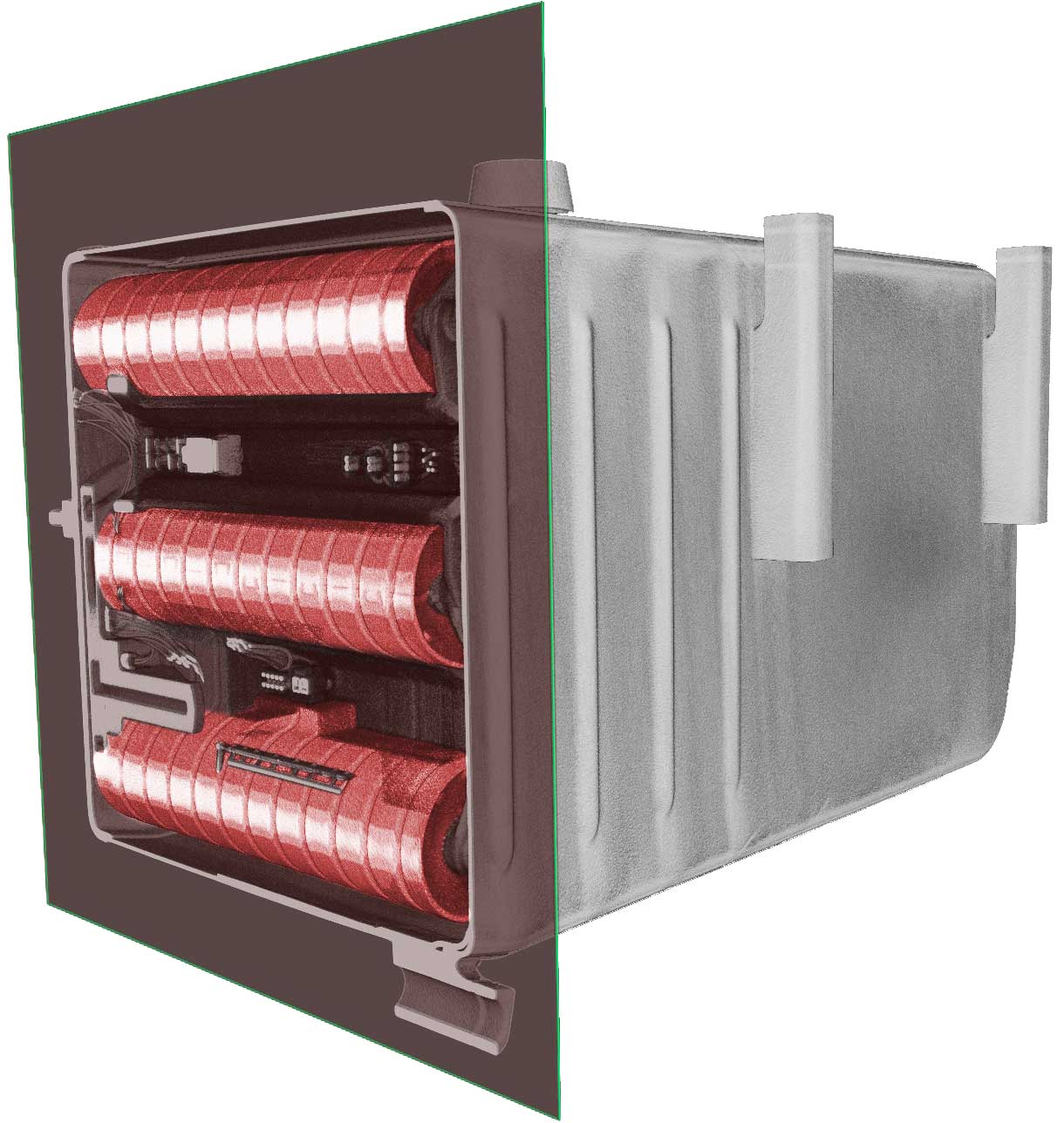

3D X-ray scanning is also known as 3D X-ray computed tomography (CT) or 3D CT. It is more advanced and complex than 2D scanning because it provides pictures based on horizontal and vertical dimensions and depth. A 3D scanner utilizes 2D images and merges them to create a 3D image of the entire object, which can then be rotated, inspected and analyzed.

2D Vs. 3D X-ray Scanning: What are the Benefits?

X-ray-based scanning technologies offer a range of benefits to analysts and can be used throughout several industries. Although X-ray scanning was initially used in the medical industry, it is now frequently used in applications throughout the following industries:

- Aerospace

- Defence

- Automotive

- Electronics

- Medical Devices

- Plastics

- 3D Printing

It offers non-destructive analysis methods to help understand more about the internal structure of a material, part, or an assembly. The following section will examine the benefits of 2D and 3D X-ray scanning.

The Benefits of 2D X-ray Scanning

2D X-ray scanning takes place under controlled conditions to project internal images of a subject onto a viewing screen. This method is used in quality control processes to determine defects or manufacturing errors.

- Analyze the integrity of a product

- Failure analysis

- Identify cracks, flaws and voids

- Quality analysis

However, the limitations of 2D X-ray imaging are critical. With this method, it is much more difficult to provide accurate information on the depth of an object or its internal structure. Due to all the product information being superimposed in a single 2D x-ray image, it can also be very difficult to interpret what one is viewing. Therefore components with complex geometry or varying levels of thickness cannot be analyzed optimally. Because of these drawbacks, 3D X-ray scanning has become a better method for certain applications.

The Benefits of 3D X-ray Scanning

3D X-ray scanning offers heightened levels of detail for analyzing an object. As we’ve already mentioned, it is extremely common in the medical industry but plays an important role in many other applications.

One key benefit of 3D CT is that it can be used to analyze complex geometries, including the depth and thickness of a sample’s features or the size of a defect in all directions. Other benefits include:

- Metrology of internal and external product features

- Size and volumetric analysis of discontinuities, anomalies and defects

- Improved quality control checks

- High spatial resolution

- Improved contrast sensitivity

- Ability to perform high speed in-line or at-line inspections and process checks

- Identifying unexpected product errors

- 360º analysis is available

Selecting X-ray Scanning Systems

There are very clear use cases when comparing 2D and 3D X-ray scanning systems; each offering advantages that are indispensable for given applications. However, despite the fact that 2D imaging will continue to find application in various industries, 3D CT is becoming the go-to technology for an ever-growing range of use cases

North Star Imaging provides a selection of 2D radiography X-ray systems and 3D X-ray computed tomography systems that can be adapted for your applications. Our X-ray scanners have outstanding resolution and are designed with accuracy and efficiency in mind.

If you would like more information on how 2D or 3D X-ray scanning systems could support your applications, don’t hesitate to contact us today.