Plastic Injection Molding

Industrial X-ray and CT for Plastic Injection Molded Parts

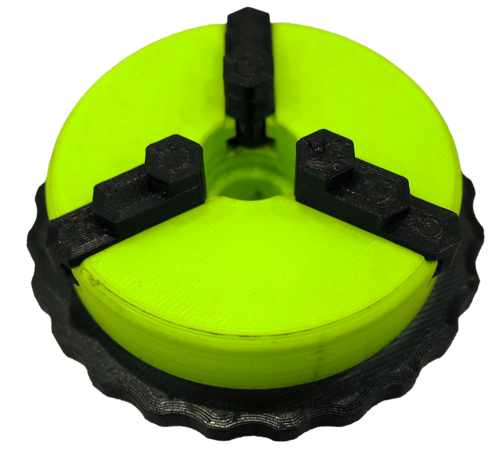

Plastic injection molding machines are designed for high-volume production of identical parts. Regular verification ensures consistent product quality, testing for visual aspects, mechanical resistance, and waterproofness.

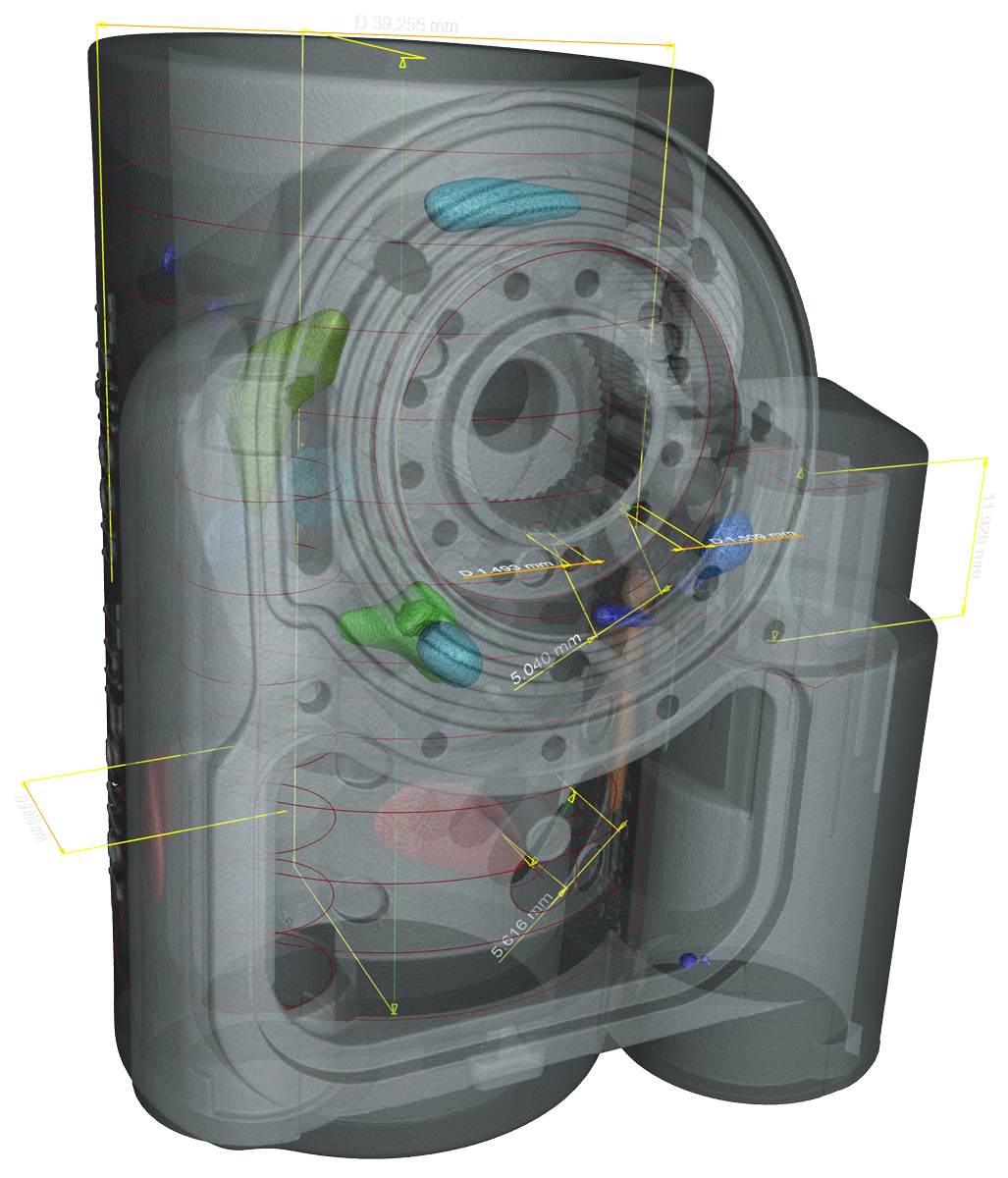

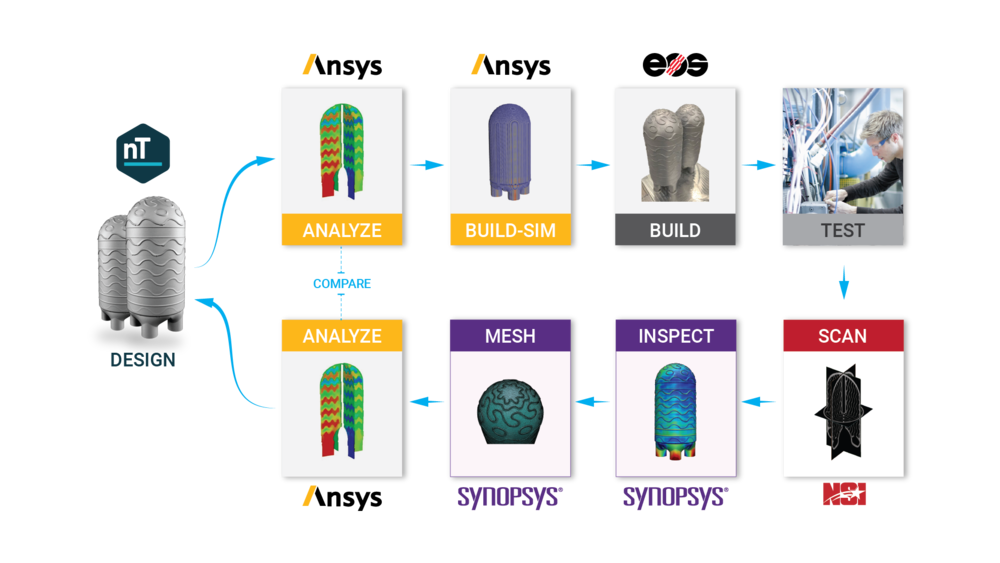

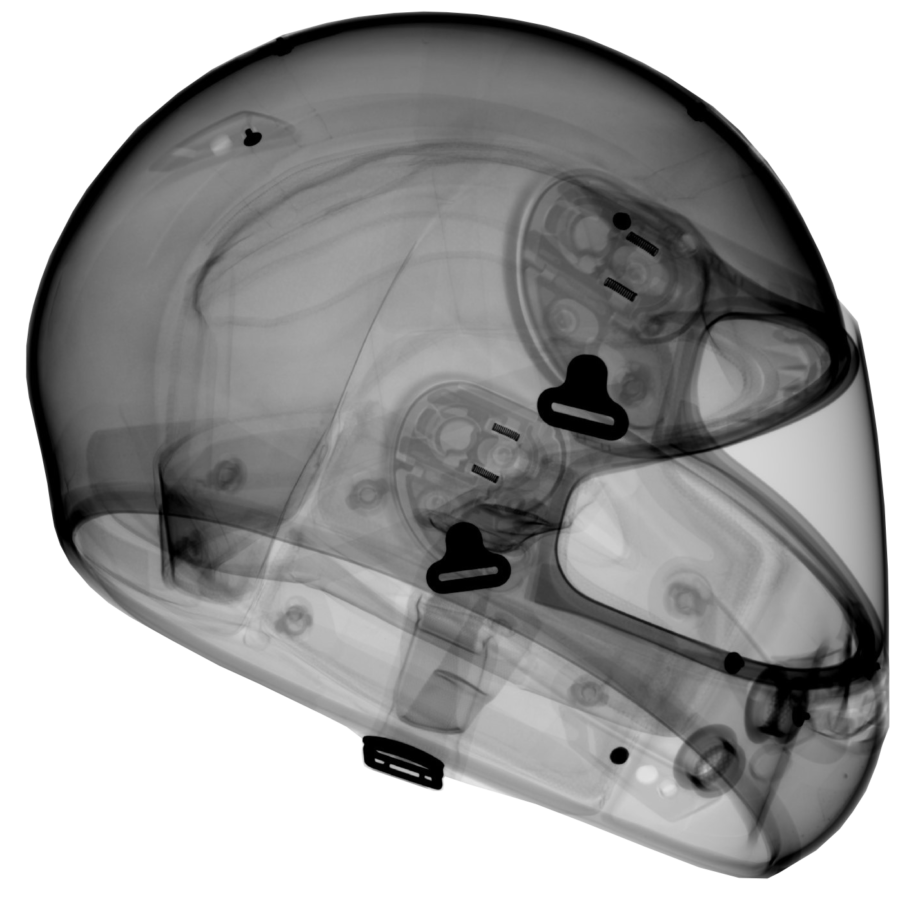

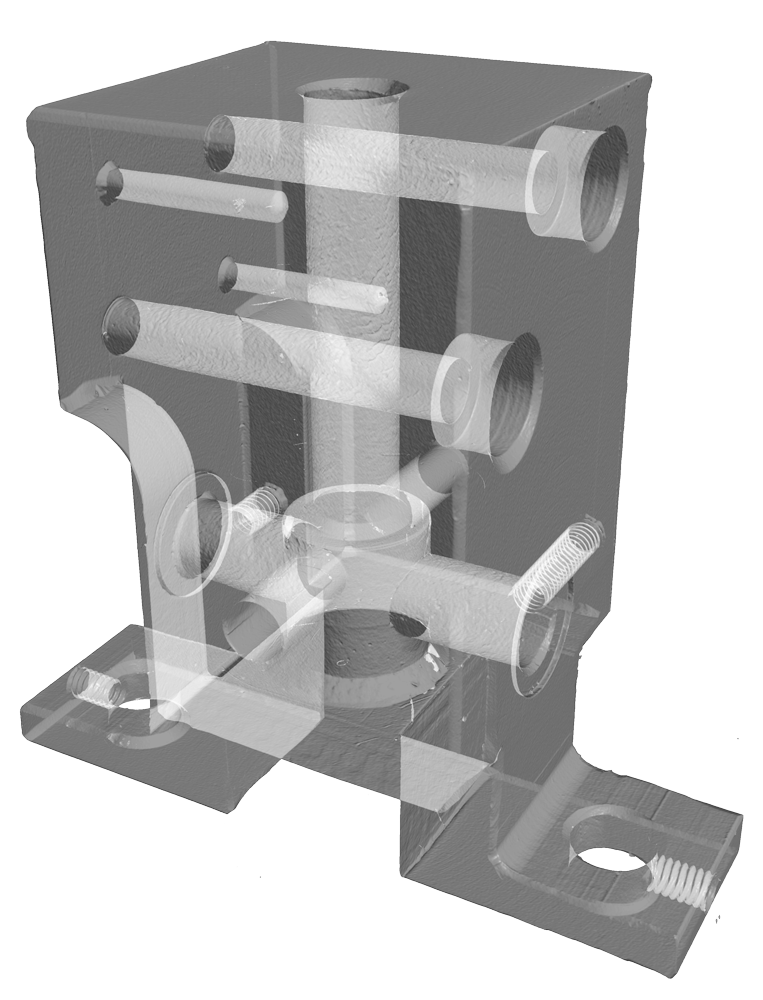

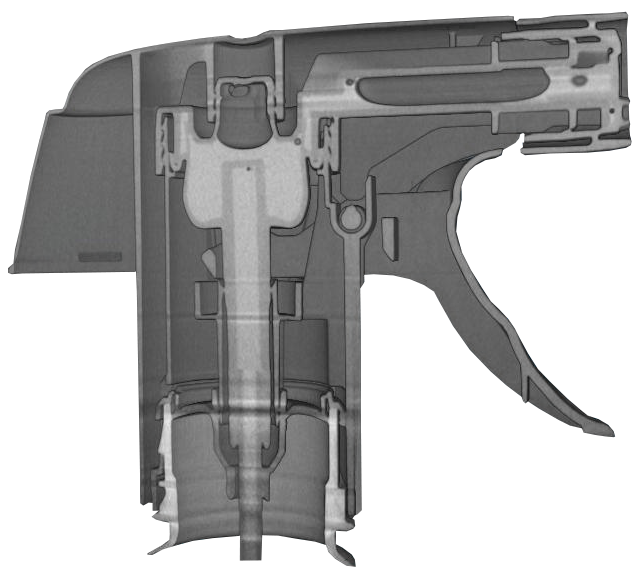

Achieving the perfect part geometry involves several optimization steps, despite advanced simulation tools. Industrial X-ray Computed Tomography (X-ray CT) is ideal for inspecting plastic parts, penetrating common materials like polyamide and polypropylene easily for precise inner and outer dimensions.

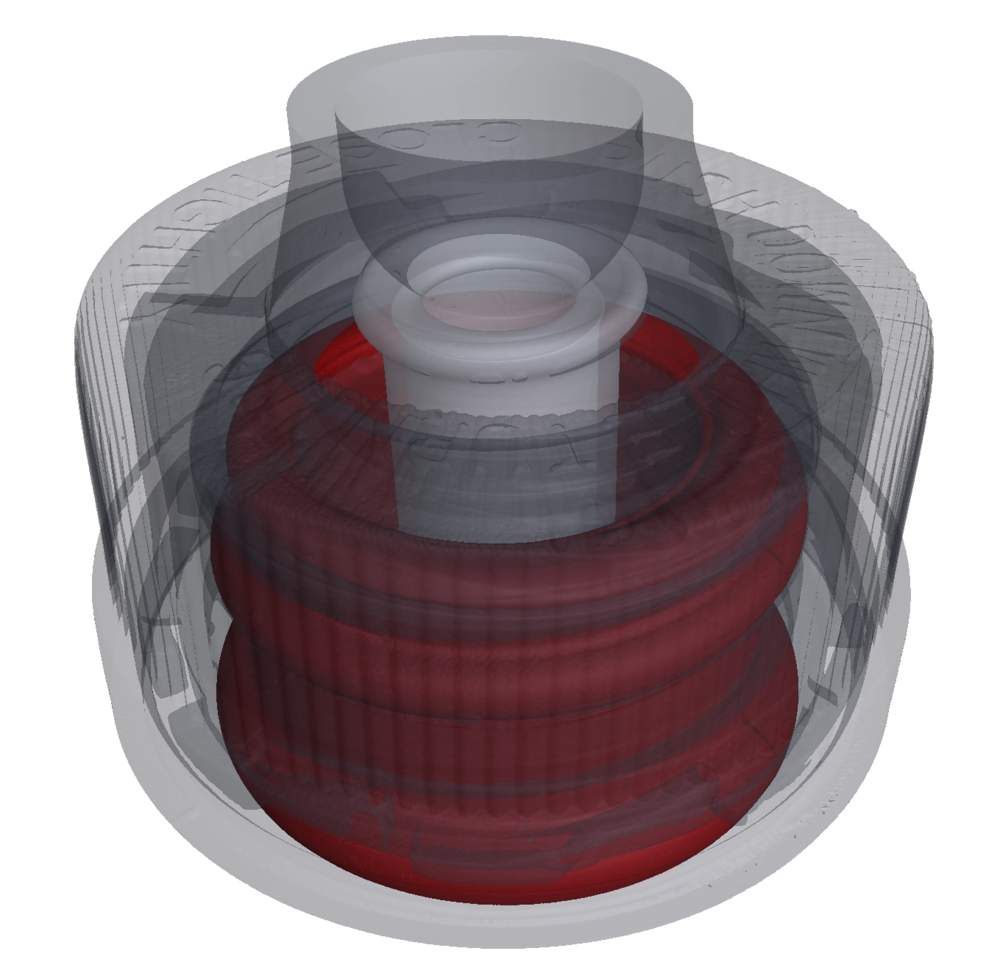

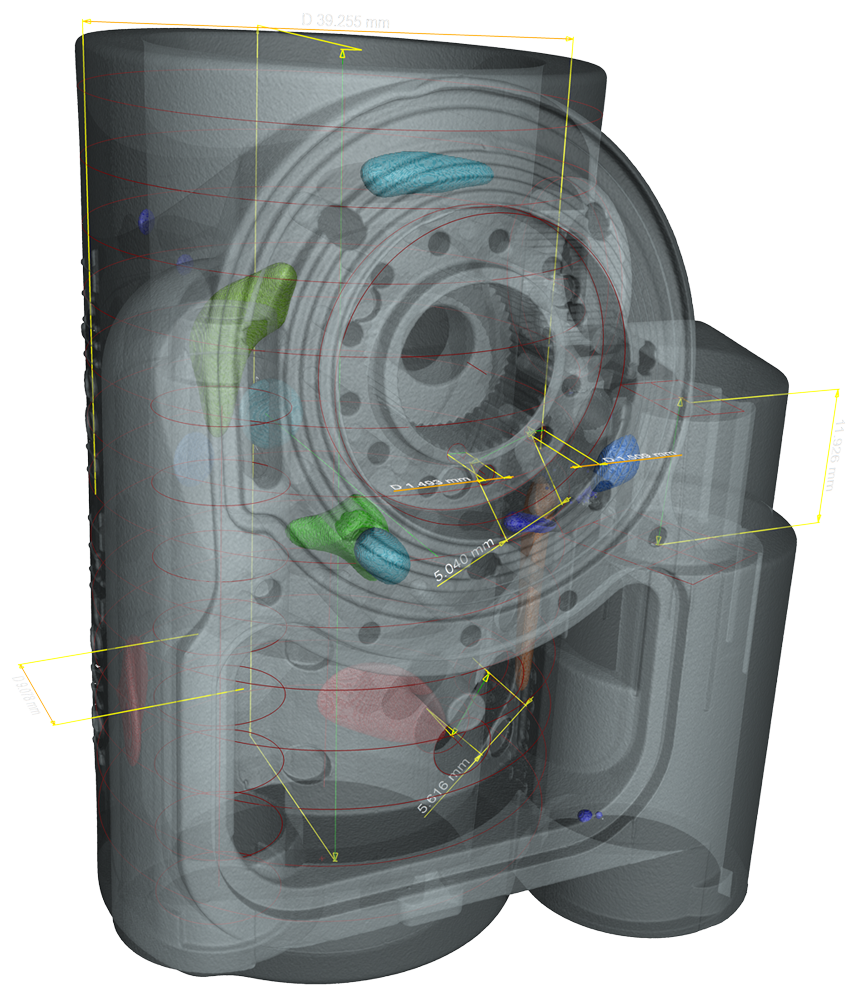

Unlike other methods, X-ray CT requires no sample preparation and can be integrated into automated production lines. It generates meshes from internal and external structures for accurate finite element analysis, aiding in optimizing mold design and identifying defects like porosities and inclusions.

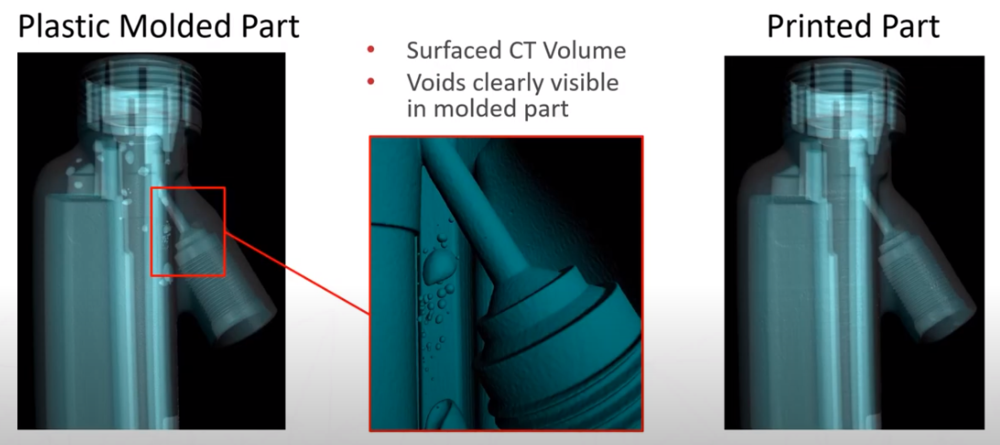

X-ray CT accelerates mold design optimization by comparing 3D models of prototypes to CAD files, allowing for efficient adjustments. It also enhances material health testing, ensuring quality by detecting defects quickly. This technology helps manufacturers save material and reduce part weight, leading to cost efficiency.

Key benefits of X-ray CT for injection molding include:

- Accurate metrology reports

- Void and inclusion detection

- Assembly analysis

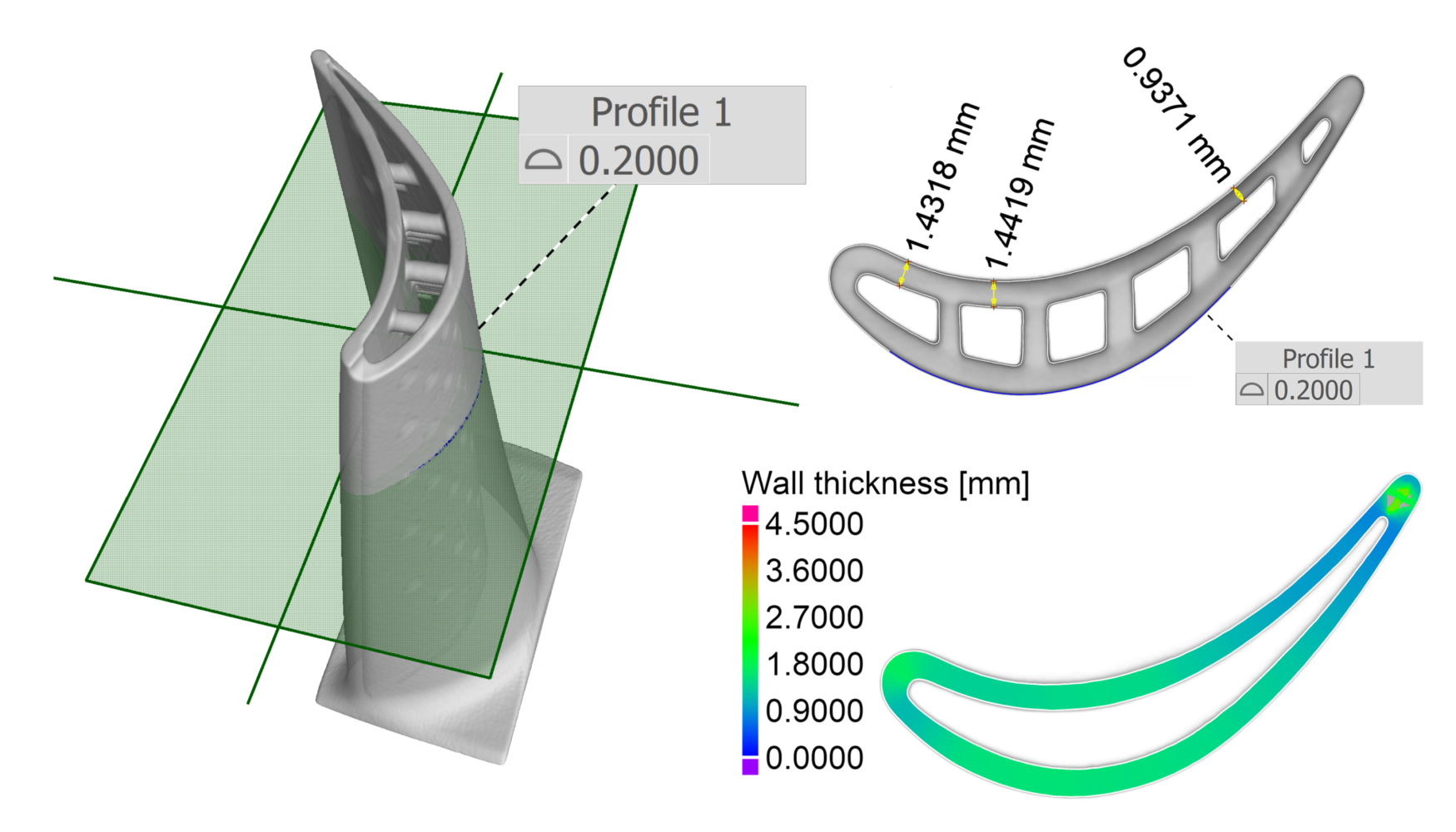

- Wall thickness distribution

- Fiber orientation statistics

Overall, X-ray CT significantly enhances the injection molding process, improving quality, reducing lead times, and minimizing costs.