X-ray Inspection of Plastics & Rubber

Computed Tomography for Plastic and Rubber Parts

Whether searching for anomalies in molding processes or establishing quantitative analyses of porosity, Computed Tomography and Digital X-ray Imaging provide invaluable assistance and assured reliability in the plastics and rubber industries.

Medical device components, electrical connectors and plastic housings are common products seen in the plastics industry. Often plastic is inspected for quality, measurements & first-article inspection, foreign material, porosity, and wall thickness analysis.

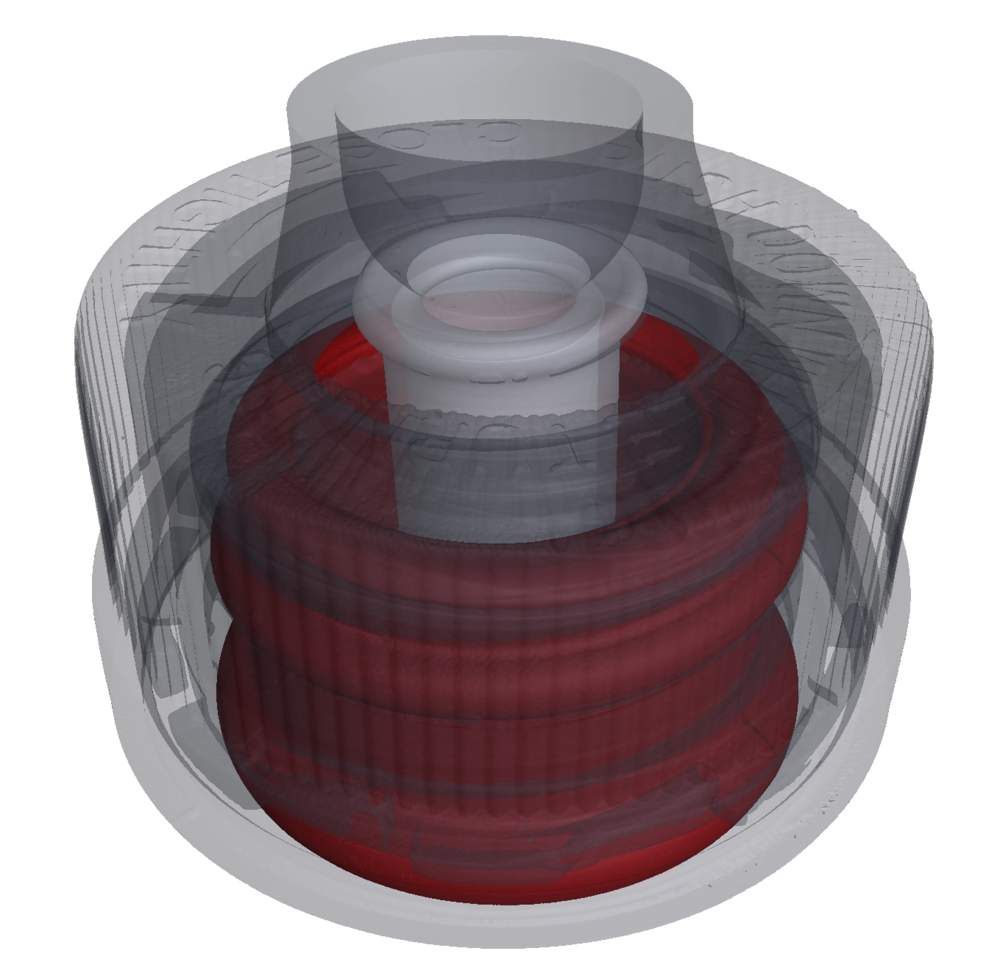

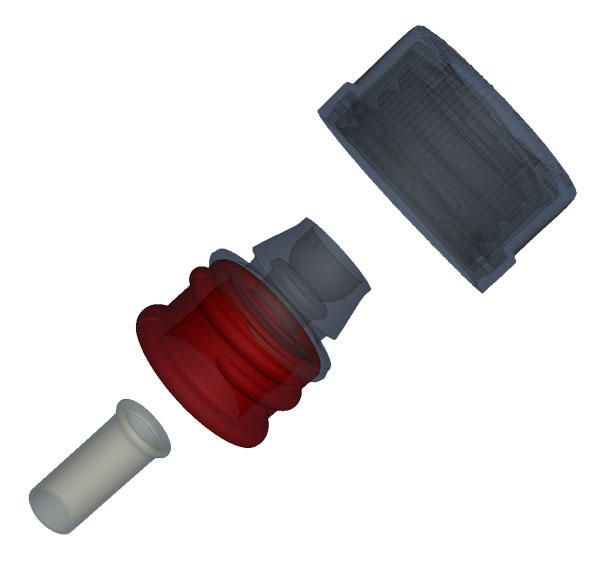

Not only can you thoroughly inspect a part quickly, but you can also inspect an assembly and see how parts are interacting. For example, this bottle cap may be scanned to see the fitment and sealing surfaces to find potential leak paths or potential interference in the assembly.

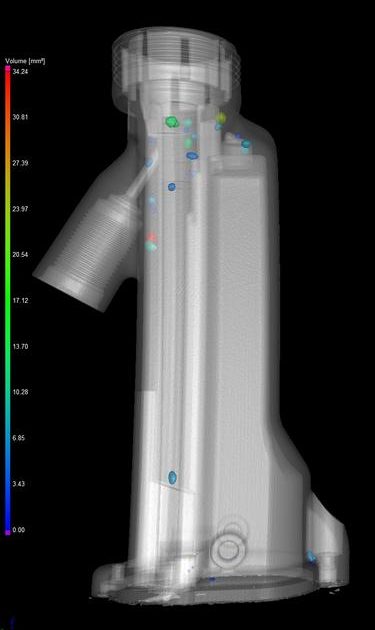

Plastics are also scanned to see porosity and inspect molds for molding process dimensions and voiding. In plastics and rubber, inclusions could indicate a problem with the injection molding process or template. The more dense the inclusion, the more likely to affect the integrity of the product.

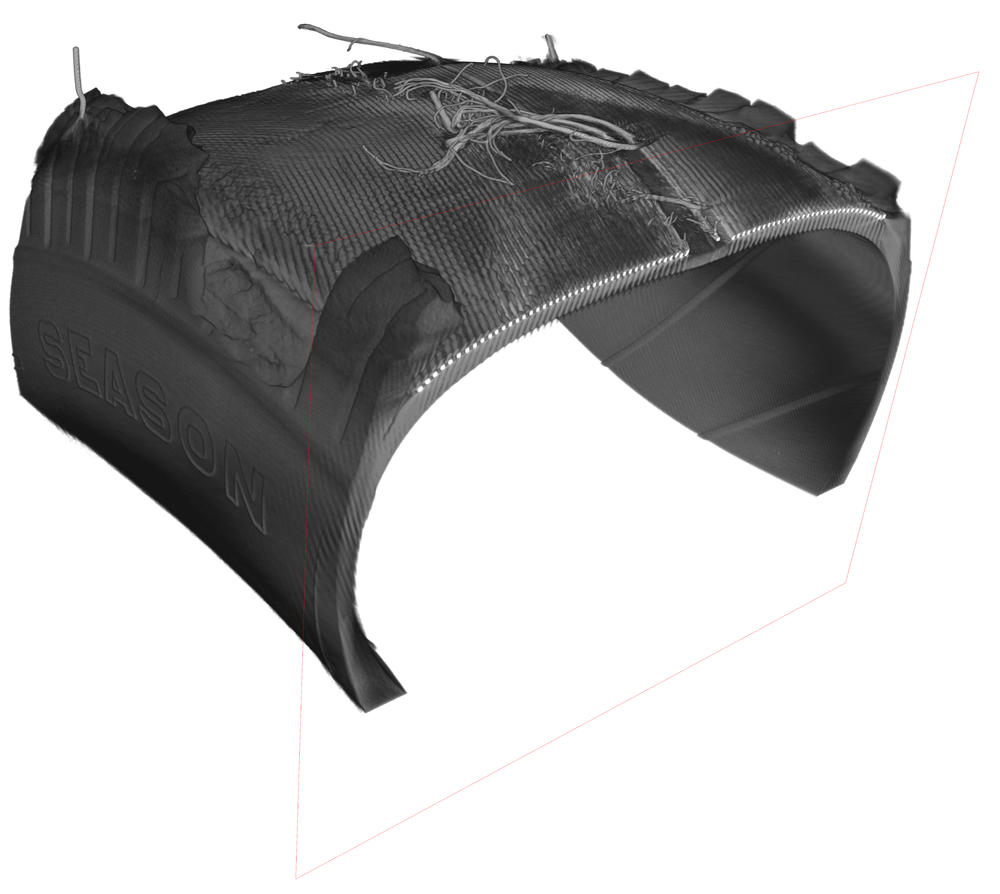

When CT scanning vulcanized rubber parts, it is possible to come across products made with layers of different kinds of rubber materials. Inspection can detect if the rubber layers stuck together properly without air pockets or de-bonding, or that the rubber has properly bonded to other structural materials in the product.

Using computed tomography when ensuring quality in plastic and rubber parts gives you a very higher level of precision and a faster verification tool.