What is Digital Radiography & How Does it Work?

Digital radiography is a modern method of 2D X-ray imaging widely used in a range of industries, including automotive and manufacturing. It is a cutting-edge technology that enables engineers to inspect components and materials for defects, flaws, and irregularities that may impact performance and compliance regulations. Originally, digital radiography was used in the medical field to help diagnose and treat various diseases and conditions, but it has since been developed further for industrial and manufacturing applications.

In recent years, digital radiography has become increasingly popular in industry because it is a non-destructive technique that offers many advantages that traditional methods cannot. Throughout this blog post, we look at the basics of digital radiography, its advantages, and its key applications.

How Does Digital Radiography Work in Industrial Applications?

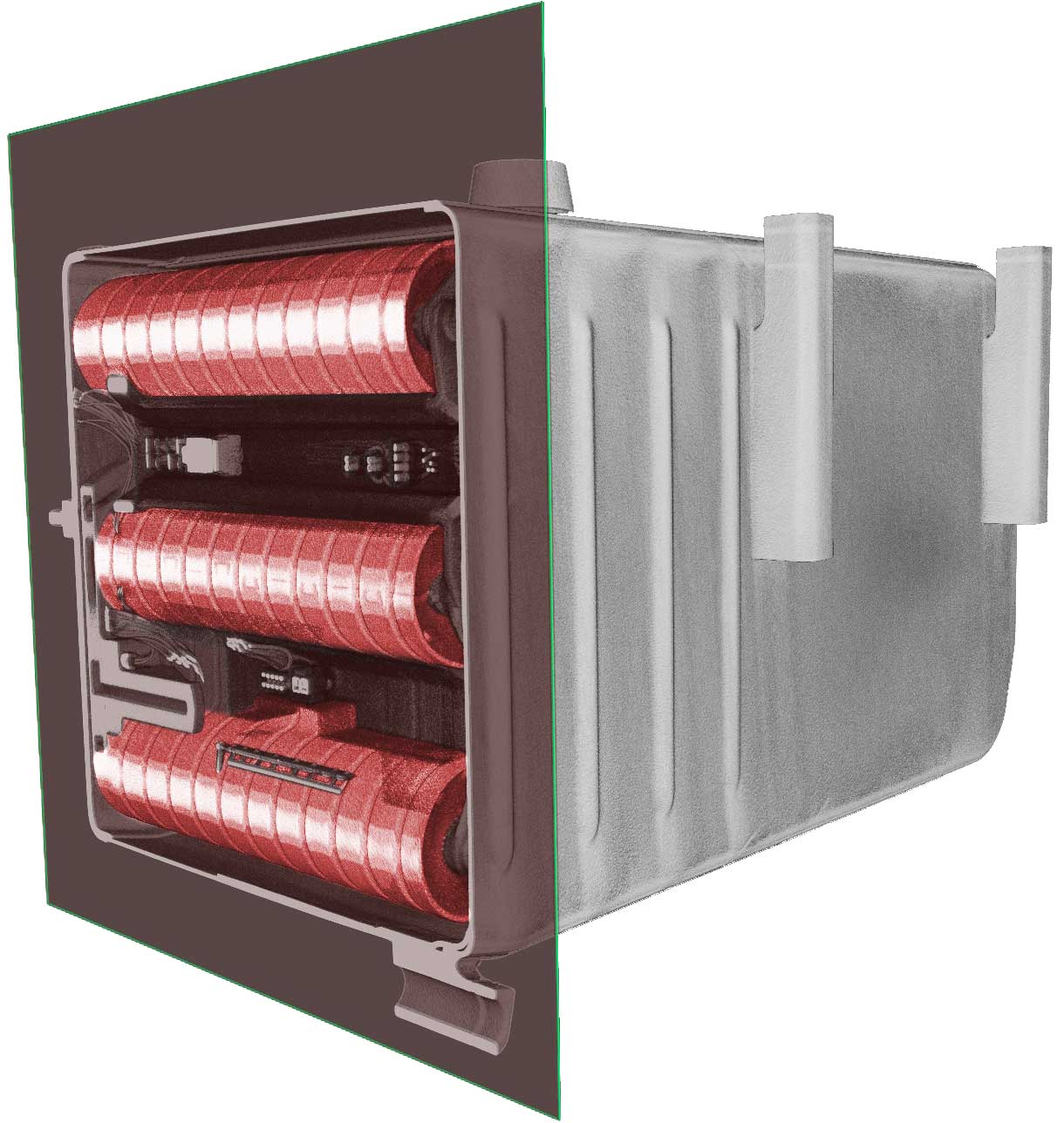

Digital radiography (DR) requires an X-ray source and a digital detector, or in the case of computed radiography (CR), a scanner with imaging plates. In digital radiography, when the X-rays are directed through the object being inspected, they are received by the detector and converted to a high quality digital image. In computed radiography, the X-rays are absorbed by the imaging plate, a laser then scans the imaging plate. The light is then transformed into a signal to produce a digital image that can be viewed on a computer monitor.

Advantages of Digital Radiography Over Traditional Techniques

In industrial and manufacturing applications, there are several reasons why digital radiography is replacing traditional X-ray film techniques, from higher accuracy and efficiency, and the additional advantages we discuss below.

Cost-effectiveness

Digital radiography is a cost-effective imaging method because it does not use the chemicals, films, and processing equipment that traditional X-ray techniques require.

Higher Accuracy and Image Quality

Digital images are produced in high contrast and resolution, enabling images to be analyzed much easier than other methods. As a result, technicians can promptly and accurately identify flaws and defects in scanned materials.

Improved Efficiency

This imaging method is efficient because data can be transferred, deleted, and edited immediately, and images are produced almost instantly. As a result, this reduces the time spent on inspection and analysis.

Lower Radiation Exposure

Digital radiography does not require as much radiation to produce images as traditional methods, making it safer for technicians, the environment, and radiation-sensitive products.

These crucial advantages of digital radiography contribute to its growing use in the industrial and manufacturing sectors, as it benefits a wide range of applications.

Applications of Digital Radiography in Manufacturing

Some of the most common applications of digital radiography in manufacturing include material inspection, quality control, and failure analysis.

Inspection

Digital radiography is ideal for inspecting manufacturing components and materials, especially castings, pipelines, welds, and other materials. Inspection is crucial for detecting defects, flaws, and other errors that may have occurred during production.

Quality Control

Quality control is essential in many industries, especially manufacturing, as it helps engineers ensure the materials are reliable and of high quality. These inspections help prevent component failures and reduce the costs of unsuitable products or unplanned downtime.

Failure Analysis

When defects and failures occur, engineers must determine the cause. Failure analysis is used across industries to identify problems with components and develop sufficient solutions.

Digital Radiography from North Star Imaging

Although digital radiography has already come a long way, it is a rapidly developing field that continues to offer more promising solutions. The future of digital radiography includes advanced software algorithms, automation, integration with other imaging techniques, and improved detectors. At North Star Imaging, we are dedicated to manufacturing the most advanced X-ray systems for various applications, as well as accompanying software and acquisition solutions.

Our efX-DR digital radiography acquisition software is designed to integrate seamlessly with our systems and CT software to enhance your digital imaging requirements. It offers high-performance processing, live measurements and histograms, and a wide range of other features.

Contact North Star Imaging today to learn more about digital radiography and the software available.