How Does Industrial Computed Tomography Work?

Industrial computed tomography (CT) is an imaging process that utilizes computer technology to create 3D internal and external images of a scanned object. It is a non-destructive technique that is used to examine components in a sample, which helps to highlight the sample structure and any damage within. This blog post will look at how industrial computed tomography works and provide an overview of its applications.

How Does Industrial Computed Tomography Work?

Industrial computed tomography uses X-rays to analyze samples. CT allows analysts to detect defects and anomalies in a component and any manufacturing process issues while providing the ability to take internal and external measurements.

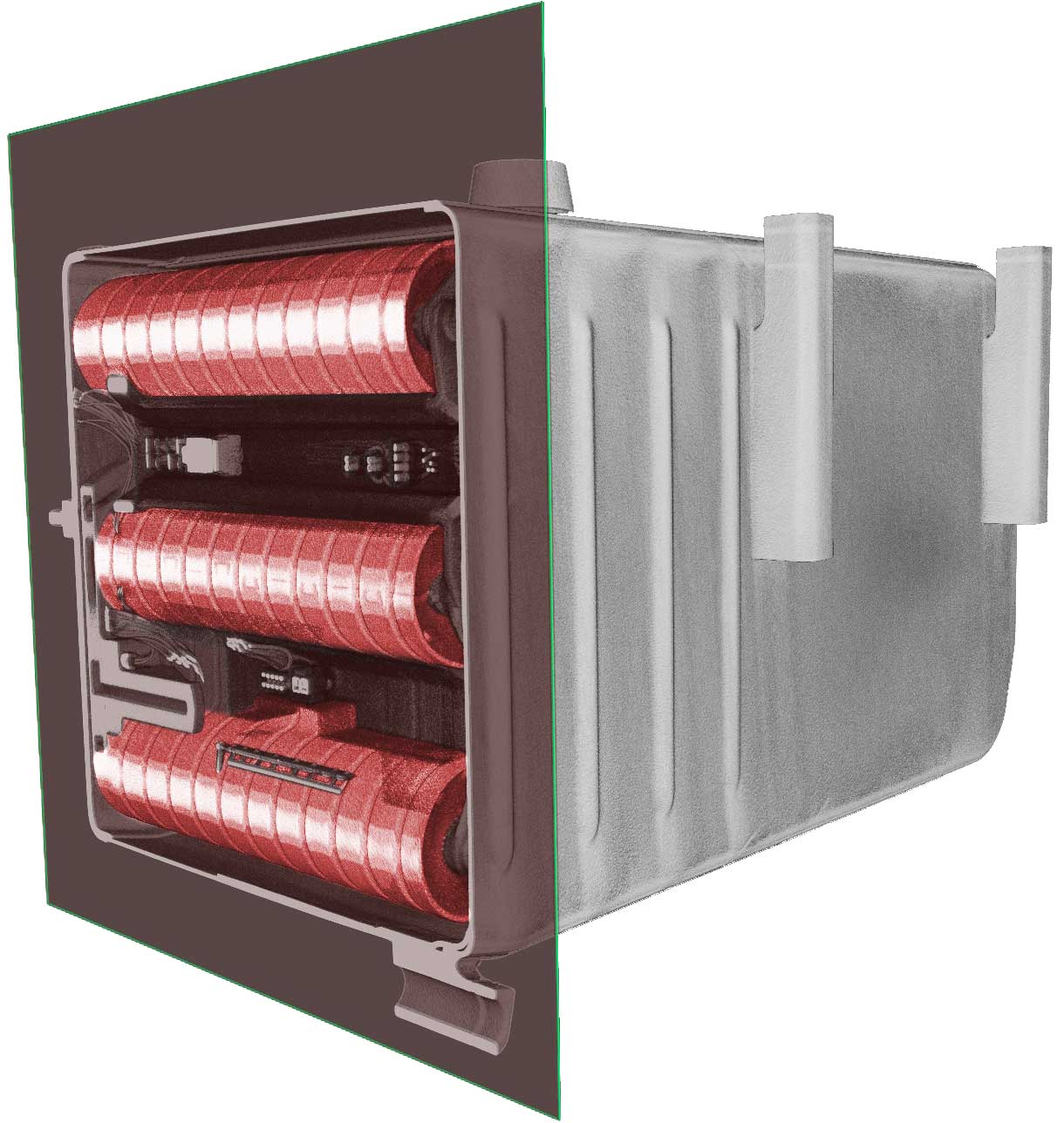

The key components in industrial CT include a rotary platform in which the sample is placed, the X-ray source and detector, and a shielded enclosure to contain the X-ray radiation. The sample is placed on the rotational table, which allows the X-rays to capture 360o of sample information as the X-rays are projected through the sample and received by the X-ray detector. The X-ray detector enables 2D image capturing which can be reconstructed into 3D volumetric data and 2D slice data. This data can then be used to perform in-depth analysis ranging from full product volumetric inspections and measurements to individual 2D slice measurements and evaluations.

The main stages of the X-ray CT measurement process chain are:

CT scan → 3D model reconstruction → Surface determination → Dimensional analysis

Industrial CT has become a preferred method of measuring samples because of its unique advantages. To start with, it is a non-destructive and non-invasive technique and can be used to perform measuring tasks that traditional measurement technologies cannot carry out.

Applications of Industrial Computed Tomography

Industrial computed tomography scanning is predominantly used in highly critical part applications such as aerospace and defense products, and medical devices. However, it benefits a range of other industries due to its non-contact methodology and unique capabilities. CT scanning is utilized in the automotive, construction, food processing and manufacturing industries, plus many others and some specific applications are outlined below.

- Additive Manufacturing: used for 2D and 3D metrology, failure analysis, flaw detection, in situ monitoring and more.

- Automotive industry: to detect foreign object debris (FOB) and failures, support research and development and test machinery.

- Electronics industry: To check for FOB, defect analysis, inspect welding and scan for broken wires and joints.

- Food industry: to analyze the integrity of food products and packaging.

- Manufacturing industry: to inspect components and ensure they are compliant with necessary regulations.

- Medical: to analyze devices, implants, internal structures, prosthetics and more.

Industrial Computed Tomography with North Star Imaging

North Star Imaging is one of the world’s leading manufacturers of 3D computed tomography. We are dedicated to providing outstanding customer service by understanding our clients’ needs and expectations and continually improving our world-class imaging products.

We manufacture a range of X-ray systems, including the X25, X3000, X5000 and X7000 cabinet systems, the RobotiX systems and MeVX high-energy and standalone manipulators. Each of our devices has its benefits and features and can be used for specific applications.

For more information, please contact one of our experts today and they will be happy to discuss your queries or schedule a live demonstration.