Approved Inspection Facility for OEM Flight Hardware

North Star Imaging’s West Coast Inspection Service office is now an approved inspection facility for aerospace OEM flight hardware. As an ISO 9001:2015 certified company, North Star Imaging (NSI) adheres to a quality management system with supporting procedures, process controls and documentation in accordance with ASTM E2698 and ASTM E2737. Having an approved location for industrial X-ray inspection gives aerospace part manufactures security and anonymity if a need for nondestructive part inspection arises. This certainly makes the certification process easier and more accurate knowing the NSI image development methods are executed per industry standards for DR and CT imaging.

The qualifications of the people working at NSI are just as important as this approval. The NSI West Coast office employs qualified and certified Level 2’s in accordance with NAS 410 for Digital Radiography and Computed Tomography. They also have industry leading ASNT/NAS 410 Level 3 support available within NSI. Each employee is trained in proprietary imaging methods used for increasing image quality. After the scan, engineering support is available for image data review with customized deliverables to the customer.

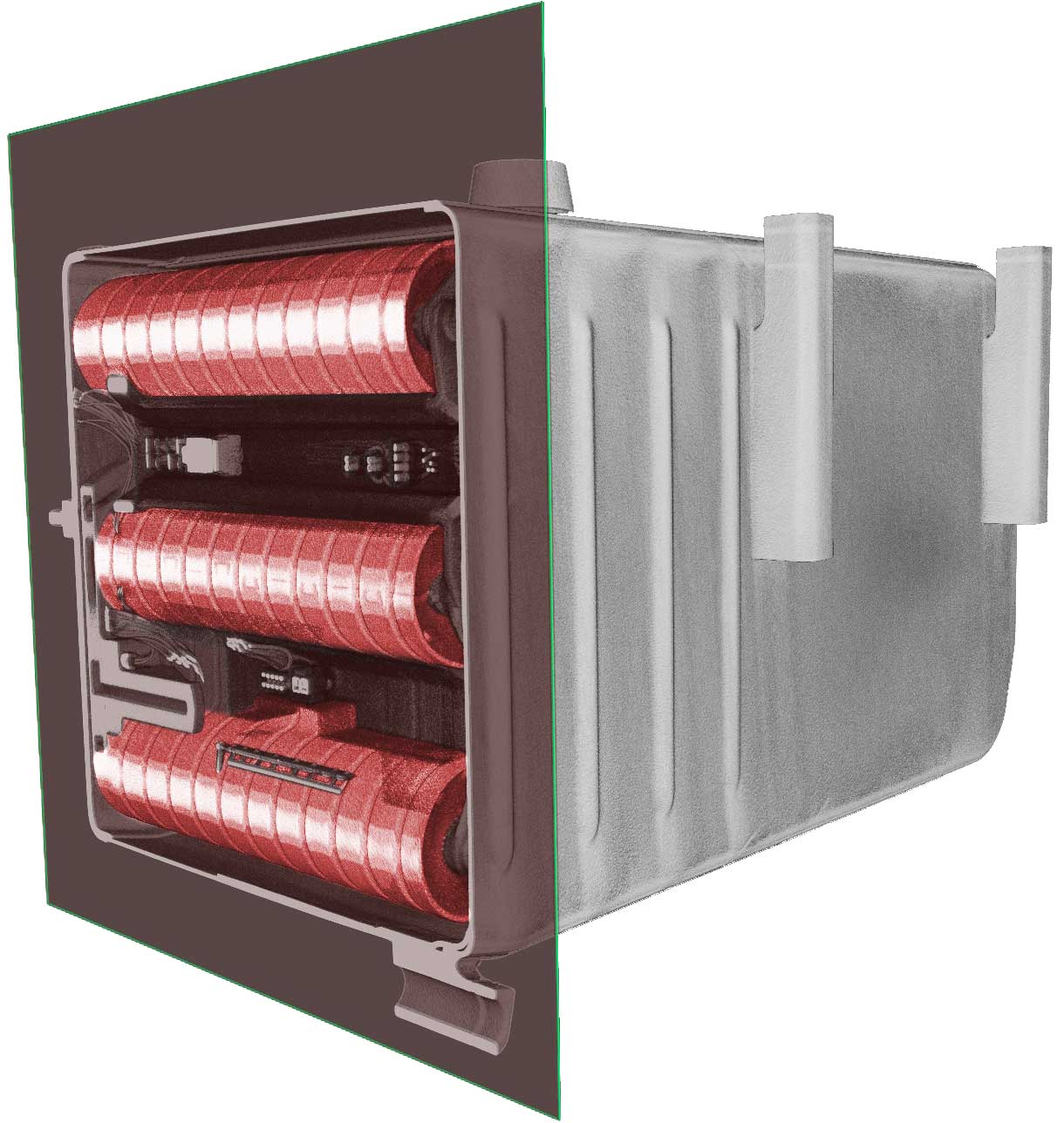

In addition to the high-level personnel, a quality X-ray system needs to be in place to generate the best quality images attainable. The NSI West Coast lab houses the X5000™ system, capable of scanning parts up to 32” by 48” at a X-ray energy up to 450kV, and a X3000, equipped with a transmission tube for greater capabilities, with a nominal part envelope of 19.5” x 24” at a X-ray energy up to 240kV.

Please contact NSI at scanning.ca@4nsi.com or 4nsi.com for more information.