Advancements in Ballistics Assessment: The Role of CT X-ray NDT

CT Scanning for Military and Defense

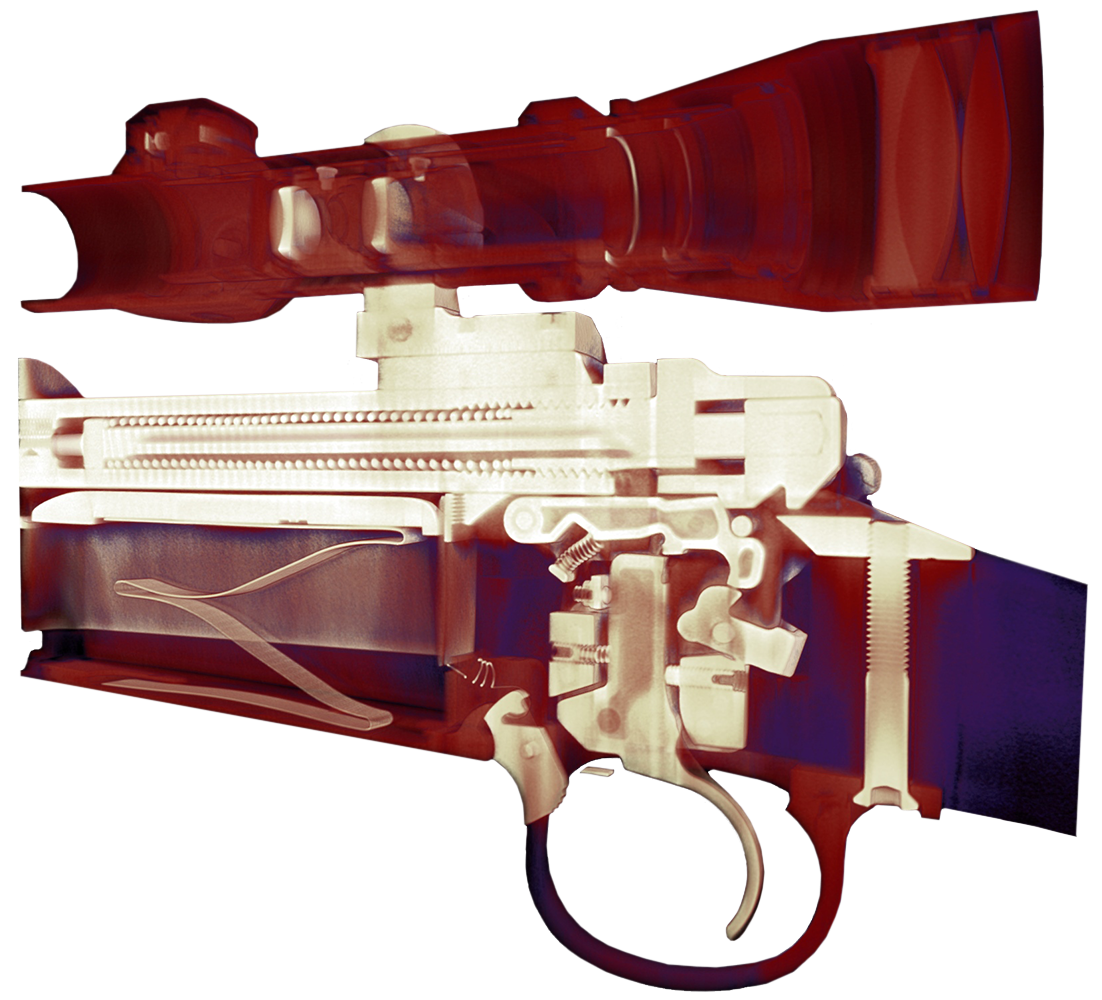

Perhaps there is no greater need for safe, accurate, and thorough assessments than in the area of military and defense, particularly in ballistics. From ammunition to body armor, the performance and integrity of these critical components can mean the difference between success and failure on the battlefield. Advanced Computed Tomography (CT) X-ray Nondestructive Testing (NDT) has revolutionized inspection of ballistics.

Ammunition Assessment: The reliability and effectiveness of ammunition are crucial factors in any military operation. CT X-ray NDT provides a non-destructive method for inspecting ammunition, allowing for detailed analysis of internal structures such as casings, propellants, and projectiles. By generating cross-sectional images, CT scanning enables inspectors to detect defects, irregularities, or foreign objects that may compromise the ammunition’s performance or safety. This technology facilitates quality control processes, ensuring that only flawless ammunition reaches the field.

Ballistics Helmets and Body Armor: Protective gear such as ballistics helmets and body armor play a vital role in safeguarding military personnel and law enforcement officers. CT X-ray NDT offers a comprehensive means of evaluating the structural integrity and performance capabilities of these protective components. Through detailed imaging, inspectors can identify defects, delamination, or material inconsistencies that might compromise their ability to withstand ballistic impact. By conducting thorough inspections, manufacturers can ensure that their products meet rigorous standards for safety and reliability.

Missiles, Rockets, and Torpedoes: The complex and high-performance nature of missiles, rockets, and torpedoes necessitates precise inspection techniques to ensure operational readiness and reliability. CT X-ray NDT enables inspectors to conduct thorough assessments of these aerospace and maritime weapons systems without compromising their integrity. By examining internal components such as guidance systems, propulsion mechanisms, and warheads, CT scanning can identify defects, anomalies, or assembly errors that may affect performance or safety. This technology plays a crucial role in quality assurance processes, helping to mitigate risks and enhance mission success rates.

Bombs and Mines: The detection and disposal of explosive devices present significant challenges for military and security forces worldwide. CT X-ray NDT offers a valuable tool for inspecting bombs and mines, allowing for detailed analysis of their internal components and explosive payloads. By generating precise images of circuitry, detonators, and casing structures, CT scanning enables inspectors to assess the integrity and functionality of these devices without resorting to destructive methods. This capability enhances the safety and effectiveness of bomb disposal operations, reducing the risk of accidental detonations and casualties.

The utilization of high energy and advanced CT X-ray NDT has become indispensable to the assessment of various ballistics applications, offering inspection of critical components with unparalleled precision and detail. From ammunition to missiles, this technology plays a crucial role in ensuring the reliability, safety, and effectiveness of military and security assets. By enabling inspectors to detect defects, anomalies, and inconsistencies that may compromise performance or safety, CT scanning enhances quality control processes and mitigates operational risks. With North Star Imaging’s configurable solutions, stakeholders in military, security, and defense get the ideally configured system, coupled with the most cost-effective combination of scanning services, training, and system maintenance to help reduce risks and help ensure the safety of our forces.

NSI is federally licensed to handle class 1.3 and 1.4 explosives and is ISO 9001:2015 certified, ISO 14001:2015 certified, ITAR registered/compliant, ASTM compliant, DOD 4145.26-M Compliant, and has ASNT & NAS 410 certified imaging professionals.