Advantages of Scanning with VorteX

A scan using North Star’s proprietary VorteX feature uses a helical acquisition instead of the more conventional cone beam approach. The source and detector simultaneously move vertically relative to the part while the part rotates. The part will typically make multiple rotations over the course of the scan and does not need to fit entirely on the detector at a given point in time.

In the correct application, VorteX can provide significant advantages over conventional cone beam CT. Understanding these advantages greatly expands the versatility of the CT system.

Benefits of using VorteX:

1. Reduction of cone beam related artifacts

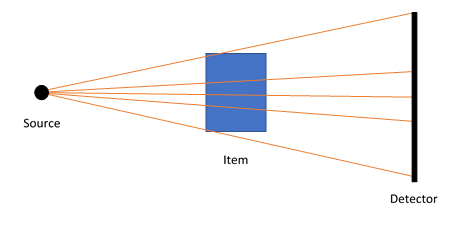

In a CT system, X-rays are emitted from a small focal spot. Then they pass through the item and are detected by a Digital Detector Array (DDA) (see Fig.1). During a conventional cone beam scan, X-rays above and below the center line pass through the part at an angle and will never align perfectly with horizontal flat surfaces in other areas of the part.

Figure 1: Setup for a CT scan. X-rays are emitted from a small source, pass through the part, and are detected by the DDA. X-Ray above and below center pass through the part at an angle.

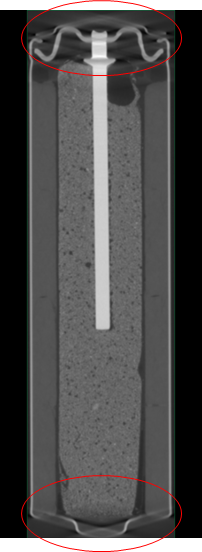

Fig.2 shows the manifestation of the cone beam artifact in a reconstruction of a battery scanned in a vertical orientation. Tilting the part can often reduce these artifacts but there are circumstances where tilting the item is physically impractical or requires sacrifice of other desirable scanning characteristics.

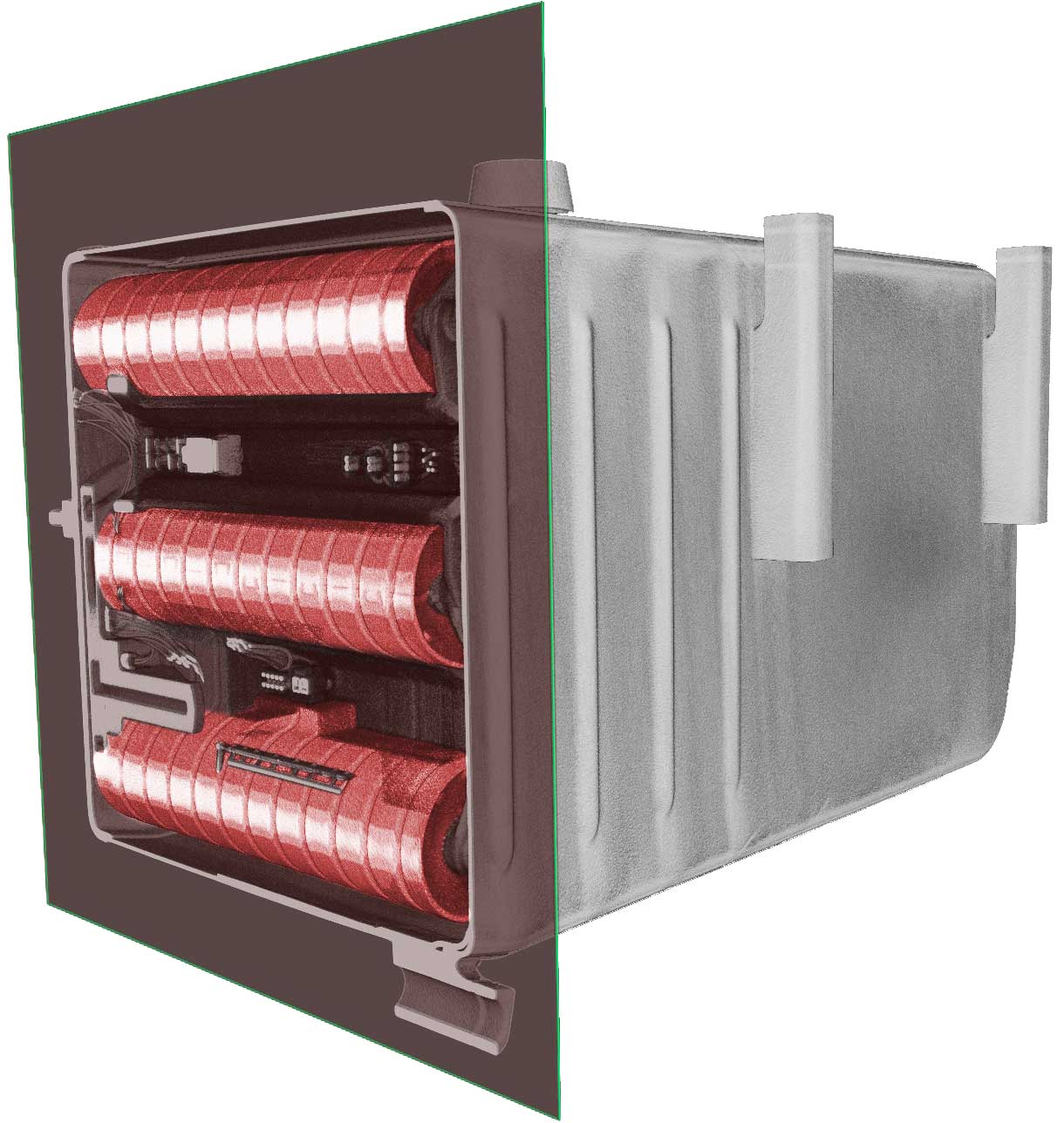

During a VorteX scan, the part travels vertically relative to the source and detector (or the tube and detector travel vertically in a different system configuration). At some point, every location of the part will align with the center of the X-ray beam, making it possible to clearly resolve flat surfaces throughout the entire part. An example is a spindle of CDs, which is essentially a stack of parts with many flat surfaces.

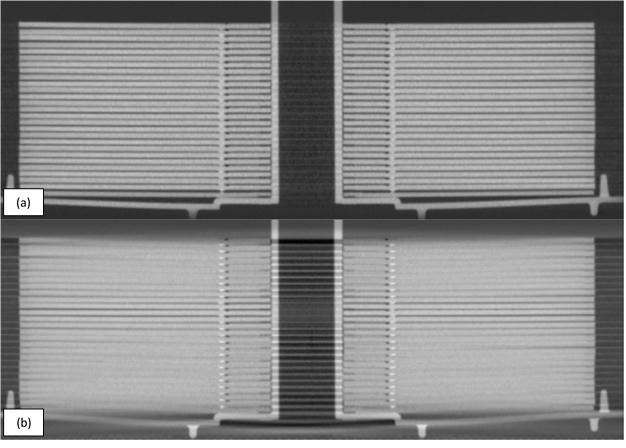

Figure 3 shows the results of scans completed using VorteX (a) and using a conventional cone beam scan (b). It is possible to clearly differentiate the boundaries in the VorteX reconstruction while they are blurred together above and below the center of the X-ray beam in the conventional cone beam reconstruction. Additionally, streaking artifacts are much more pronounced in the conventional cone beam scan (b).

2. Ability to cover a larger vertical part area with a smaller pixel size.

Due to the aspect ratio, a long and narrow part will not easily fit on a detector. A slender small item requires a significant drop in magnification and large items simply will not fit. Multiple scans provide a potential solution. However, this multi-scan technique is often time consuming, requiring several set-ups and reconstructions. Moreover, it is often desirable to have a single reconstruction output for data review purposes. VorteX provides a vertical scan envelope which is only limited by the travel of the CT system.

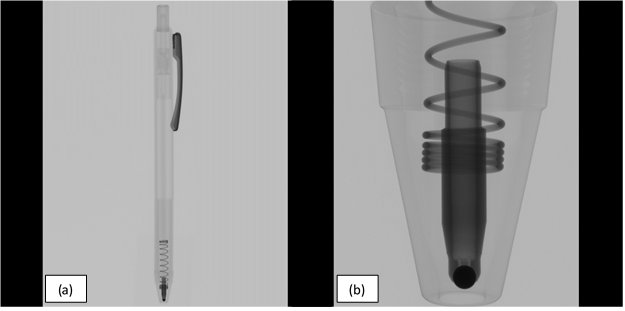

Creating a CT technique is often a balancing act between achieving enough resolution to see features of interest and ensuring coverage of the entire region of interest. Take, for example, a pen. A pen could be imaged in a single cone beam scan (fig. 4a shows the projection image), and that is a great way to look at the overall assembly providing the lower resolution is acceptable. A focused, higher magnification scan could be used to look at a specific area of interest, such as the tip (fig. 4b). But what if the goal is to analyze the entire pen for pores as small as 50µm?

A full pen projection would only yield an effective pixel pitch of 80µm, not nearly small enough to detect 50µm pores. The focused region scan would provide enough resolution but would require many conventional cone beam scans to cover the entire pen. The benefit of VorteX in this case is to provide a method of combining vertical coverage with higher resolution in a single scan.

A Few Other Factors to Consider:

Unlike in a conventional cone beam scan, a VorteX reconstruction will not use information from every projection to determine the value of a given voxel because that area of the part will not always be on the detector (or near the center of the detector in the case of a VorteX scan with a small helical set height). Given that a similar number of projections contributing information are still necessary to create a reconstruction of comparable quality, the number of radiographs in a VorteX scan must be increased accordingly. This means a single VorteX scan will likely have a longer acquisition time, more data acquired, and increased reconstruction processing time. In addition, the reconstructions have the potential to be much larger in data size, particularly when VorteX is used to combine vertical coverage with higher resolution.

VorteX has many software settings that can be fine-tuned depending on the goals of the scan. An item with closely spaced flat surfaces, such as the stack of CDs in Fig.3, will require many revolutions to eliminate the cone beam artifact. In an item like a pen (Fig.4), it is often possible to scan with a wider helical pitch.

In conclusion, VorteX offers several advantages that can expand the capability of a CT system. The reduction of cone beam artifacts can have a significant improvement in a part with many parallel flat surfaces and the vertical travel provides more options for elongated parts. Not all items can benefit from VorteX, but it is one more tool North Star provides for optimizing CT.