Accelerating Product Analysis with Real-Time X-ray Inspection

Real-time X-ray inspection can accurately identify components beyond the surface level. These components include the configuration, integrity, and quality levels of an object. Real-time X-ray systems enable analysts to accelerate product inspection by enabling extremely high-resolution image acquisition with minimal wait times. This blog post will examine how real-time X-ray inspection is an excellent solution for enhancing product analysis.

What is Real-Time X-ray Inspection?

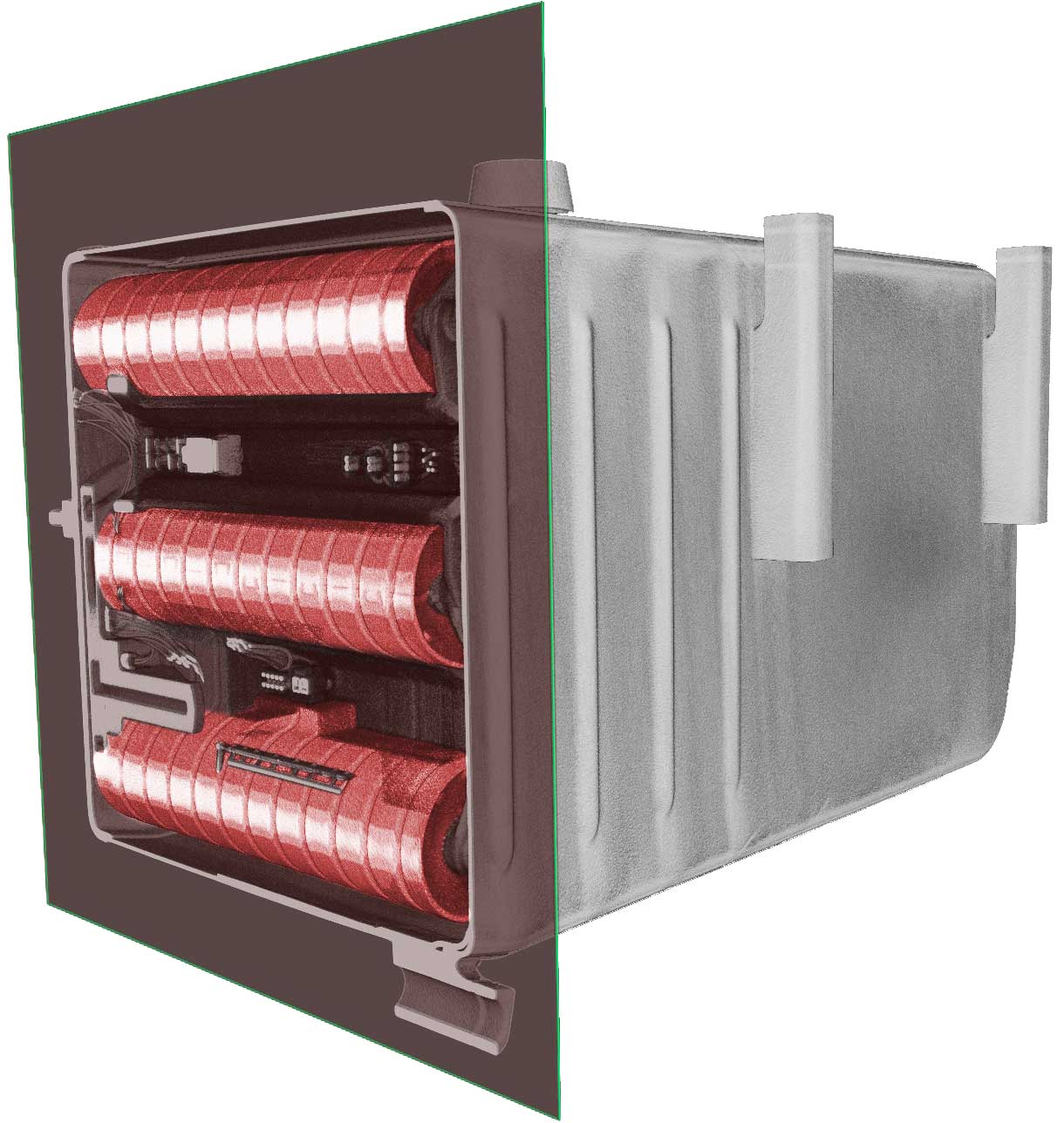

Also known as 2D digital radiography, 2D X-ray inspection or real-time radiography (RTR), real-time X-ray inspection is a method of analysis that uses X-rays to produce real-time digital images for identification purposes. X-rays penetrate the product and are captured by the X-ray detector on the other side. Once received, the X-rays are converted into visible wavelengths of light, which can be used to create high-resolution images instantly.

One of the main aspects of real-time X-ray inspection is that no film is involved in producing X-ray images like in traditional methods. This aspect provides several advantages to the applications that use real-time X-ray inspection.

What are the Benefits of Real-Time X-ray Inspection

Real-time X-ray inspection, or real-time radiography, offers analysts several crucial benefits when analyzing a product. If you are old enough to remember taking photos with a film camera, you might recall how long it took for the film to develop and that it could have been days before you received your images. Digital imaging options now provide instant pictures that can be viewed, analyzed and stored, which is no different in real-time X-ray inspection.

Other benefits include:

- Cost-effective: Fewer people are required to work with the real-time processes, allowing managers to place their staff more efficiently in other roles.

- Immediate results: High-resolution X-ray images can be displayed and analyzed in real time, and there is no need to wait for a film to develop

- Non-invasive: The method will not damage or distort your product as X-ray imaging is a non-contact technique

- Time-saving: As images are displayed instantly, and there are no film processing times, this drastically reduces the amount of time spent in the analyzing stages

- 360o view: The product can be rotated to allow the X-rays to capture a 360o of it, which then provides a comprehensive set of images to be reconstructed into a 3D volume for further analysis

North Star Imaging 2D Radiography Services

North Star Imaging has developed leading 2D digital and radiography products for customers worldwide. Not only do we supply the products, but we also offer a range of 2D radiography services that include real-time analysis of your sample, failure analysis, live manipulation and product screening for contamination screening.

If you want to improve your experience of real-time X-ray inspection or require more information about our products, contact us today and let us help you.