7 Key Uses of X-ray Metrology

X-ray metrology is one of the preferred non-contact measurement techniques used to probe a sample’s surface dimensions. It is an extremely precise technique based on computed tomography (CT), where coordinates are derived from X-ray interference at the surface of a production part. There are numerous advantages of X-ray CT compared with mechanical probes and other optical coordinate measuring machines (CMMs); namely precision, repeatability, non-destructiveness, and the ability to measure interior structures. So, where can X-ray metrology be deployed?

What is X-ray Metrology?

Before discussing the applications of X-ray metrology, it is worth reiterating its basic working principles. Metrology is defined by the International Bureau of Weights and Measures (BIPM) as “the science of measurement, embracing both experimental and theoretical determinations at any level of uncertainty in any field of science and technology”.

X-ray metrology is typically available in 2D or 3D methods, but 3D metrology has grown in popularity as advances in critical technologies have increased its applicability to an extensive range of applications. 3D metrology has been enhanced by using X-ray computed tomography (CT), which allows analysts to view and explore a sample’s internal and external structures to gain in-depth information about a product. CT is an innovative method of measuring components that provides numerous advantages over using CMMs, such as its non-contact and non-destructive method of measuring a sample and the ability to analyze a structure internally.

What are the Key Applications of X-ray Metrology?

Metrology also encompasses the theoretical and practical aspects of measurement and how it can be applied. It supports manufacturers and business owners in maintaining regulatory compliance, such as ISO, assessing product and process quality and many other aspects. Below, we will look at some of the critical applications of X-ray metrology.

Additive Manufacturing

Additive manufacturing is an advanced manufacturing technology that offers numerous benefits. However, one of its drawbacks is that products often require post-processing. Using metrology, post-processing errors can be highlighted, components can be measured with high precision, and it can help reduce energy consumption and scrap metal.

Automotive

The benefits of utilizing metrology in the automotive industry are enormous. Manufacturers must be able to guarantee their products’ quality to ensure their consumers’ safety. Metrology is used to ensure the accuracy and reliability of components, check they are aligned and fitted correctly, and maintain regulatory compliance. X-ray metrology can also inspect the machinery used to manufacture automotive parts by measuring the components produced and checking they meet the required specifications.

Electronics

Electronic components require absolute precision to support the function of their products. 3D metrology is utilized in the electronics industry because complex geometries and tiny components must be accurately produced and fitted. The edges, layers and thickness of manufactured pieces can be measured quickly and precisely to assess product quality and reliability.

General Manufacturing

In any manufacturing plant, metrology can ensure specifications are met, product quality is monitored, and legal compliance is adhered to. This is possible by using metrology to calibrate machinery and measure manufactured products. As with any piece of equipment, machinery can be worn down over time, and this could lead to incorrect product specifications and unacceptable tolerances; thus, metrology helps to rectify these errors.

Medical

X-ray metrology plays an essential role in the medical industry because it enables the measurement of medical devices used to diagnose and treat conditions and diseases. It is also used to measure patient prosthetics and other similar products. Metrology can ensure medical devices operate within legal requirements and support the development of new medical technologies.

Semiconductors

Thin film metrology is used in the semiconductor industry to measure the thickness of thin films deposited onto a substrate. It is crucial to measure thin film thickness because it can impact the product’s electrical, optical and mechanical properties. Metrology is used because of the high levels of accuracy provided by X-ray equipment, such as CT systems.

Space

The aerospace industry requires extreme accuracy and precision when manufacturing products and systems. Metrology is used to inspect engines, landing gear and other critical parts, structural components and fixtures. It can also support maintenance checks and ensures components are aligned correctly.

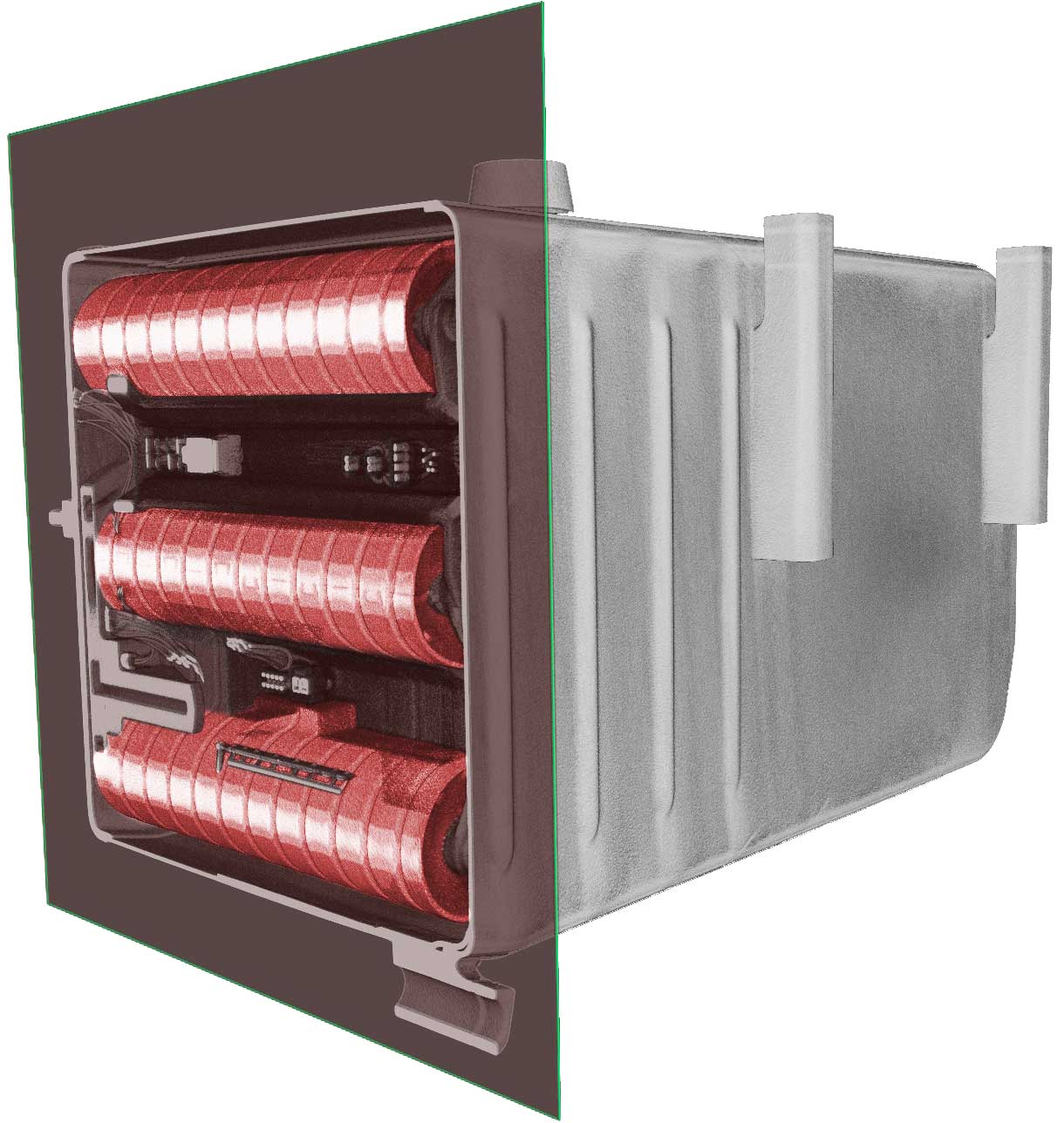

North Star Imaging and X-ray Metrology

North Star Imaging designs and manufactures X-ray systems to support the science of measurement: Metrology. Our products allow accurate and precise measurement of internal and external structures in various applications and have the benefit of being non-contact and non-destructive.

Contact us today for more information about how X-ray metrology can benefit your business.