Using Industrial CT Manipulators

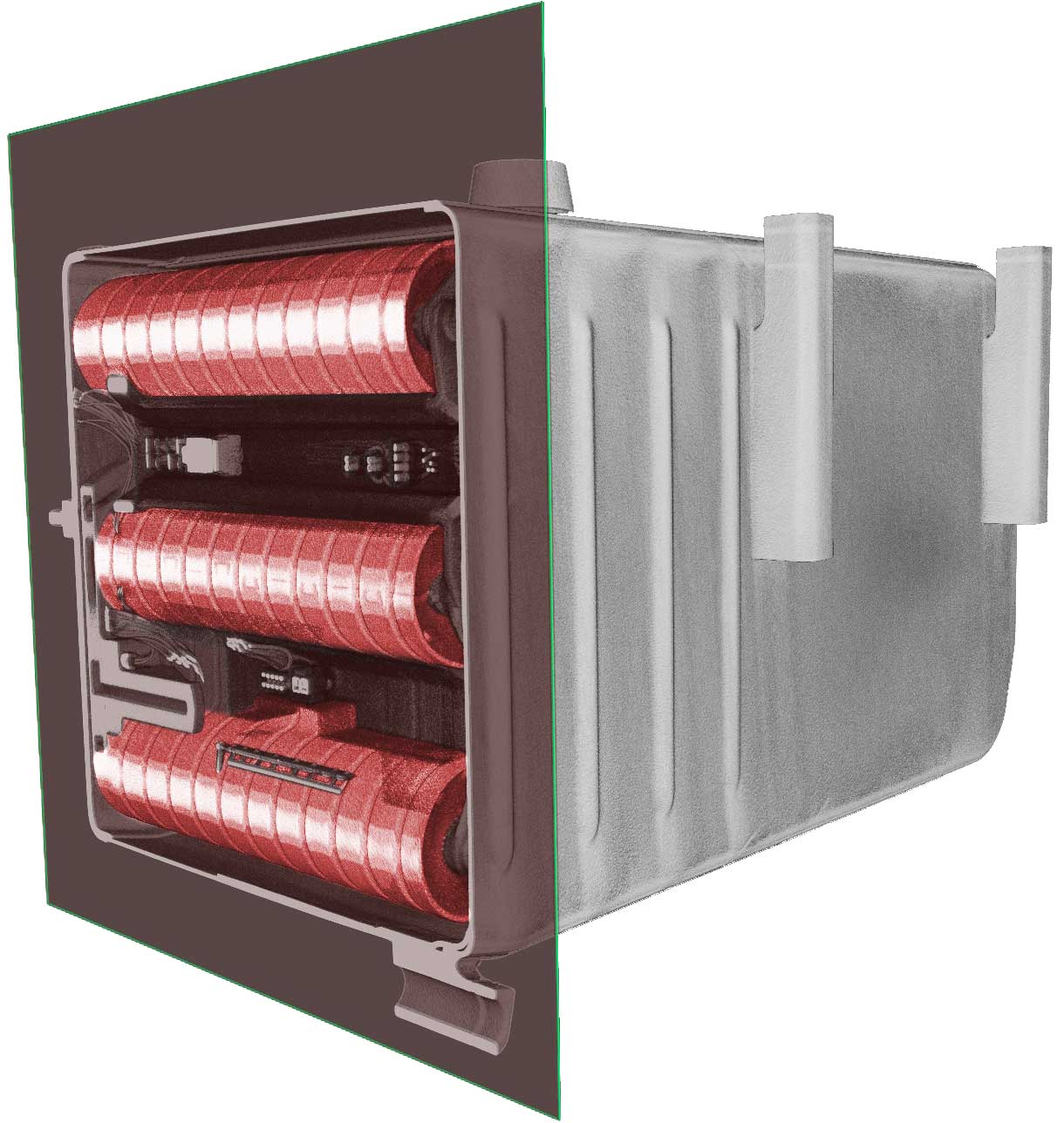

X-ray scanning is an invaluable tool for product inspection, enabling users to visualize the internal structures of objects with extreme precision. Computed tomography (CT) magnifies the capabilities of conventional X-ray imaging, by combining two-dimensional cross-sections into a three-dimensional profile. This allows users to create 3D images of their products; internal structures and all. However, creating reliable 3D images via CT requires absolute precision when positioning the X-ray source, detector, and part. Precision manipulators can play a critical role in the CT process.

Sometimes, manipulators comprise complex robotic arms with multiple degrees of freedom and sophisticated end effectors, allowing users to maneuver large parts with extreme accuracy. Yet many scenarios require a simpler solution with greater precision. Industrial CT scanning can be accomplished using a precision 3-axis turntable to correctly position a component for scanning. This blog post will dive into a bit more detail.

What Are Manipulators?

One eponymous robotic manipulator is the automated turntable, providing a simple rotary action that allows parts placed on the surface to be turned 360° around a central axis. Finding the optimal position for CT scanning can be a tedious process. Automating part positioning can yield significant time-saving results, and in the case of heavier loads, can lead to safety improvements. The 3-axis manipulator is a perfect solution, providing rotational motion combined with horizontal, vertical, and source to detector movement.

An added benefit of the 3-axis turntable system with precision manipulator is the ability to use it in a standard cabinet system or a standalone environment, such as a shielded vault.

Parts placed on the turntable can be adjusted in three axes and rotated a full 360° degrees for optimal CT scan positioning. These systems are ideal for a range of applications, including:

- Assembly Verification

- Failure Analysis

- Internal and External Measurements

- Material Analysis

- Quality Control

- Product Compliance

- Research and Development (R&D)

- 2D and 3D Metrology

Manipulators for Industrial CT with North Star Imaging

North Star Imaging has been manufacturing 2D digital and radiography and 3D computed tomography equipment since 1986, and we are innovating daily. We have worldwide locations from which we provide expertise, demonstrations, and client support. Our product line includes industrial CT systems suitable for various applications such as failure analysis and product quality compliance.

X5500

Our X5500 standalone manipulator is an industrial CT X-ray inspection system that is highly versatile. It is suitable for large parts up to 227kg but can analyze smaller components. The manipulator offers 360o continuous rotation, and each axis can be controlled independently, allowing a wide range of movements.

Contact a member of our NSI team today for more information on how manipulators are used in industrial computed tomography CT scanning or if you would like to make a purchase.