Key Advantages of Digital Radiography

Digital radiography is a powerful analytical tool used for the non-destructive imaging of components and internal structures in industrial applications. Through a combination of X-rays with digital detectors or imaging plates, this technique enables researchers to promptly produce high-quality images that can be used to detect flaws, defects, and abnormalities in products.

Over the past decade, there has been a significant shift from traditional methods to digital radiography in industrial settings. This shift was primarily driven by the need for faster and more efficient inspection processes and better image quality. While traditional radiography has limitations in terms of image resolutions, processing time, and storage, technological advancement has enabled a solution to these issues: digital radiography. In this blog post, we look at the key advantages of digital radiography in industrial settings.

Digital Radiography

There are significant benefits to using digital radiography for various industrial applications that could not previously be obtained. From higher resolution images and more efficient inspection workflow, non-destructive testing capabilities are now more accurate and reliable thanks to digital radiography technology.

Improved Image Quality and Clarity

Digital radiography provides images of enhanced quality and clarity due to improved contrast and dynamic range. Additionally, digital radiography offers higher resolution than traditional radiography methods, allowing better visualization and analysis of internal structures and enabling accurate defect detection and characterization.

- Easy to view defects

- High-resolution imaging

- Improved contrast and dynamic range

Time Efficiency and Workflow Optimization

Some factors contribute to the efficiency of digital radiography, which in turn supports workflow optimization. The key difference between digital and traditional radiography is that digital radiography enables rapid image acquisition, removing the need for film processing – a time-consuming method that requires chemicals, darkrooms, and specialized equipment. With digital radiography, images are captured digitally and can be instantly viewed. Thus developing a fast, more efficient imaging method allows users to make decisions on the spot and supports faster inspection processes.

- Instant image viewing

- No more time-consuming processes

Cost-effectiveness and Resource Optimization

There are several ways in which digital radiography is a more cost-effective process. Firstly, film and chemical processing is not used in this method, which saves money on the buying, storing, and disposal of film and chemicals and additional labor costs.

Secondly, digital radiography works with advanced digital storage and retrieval systems, and physical options are no longer needed. Digital images can be easily stored, organized, and accessed whenever needed, which also reduces retrieval time.

Finally, archiving and sharing images is now an easy process. Digital images can be safely archived in digital formats and easily shared with those requiring them. Not only does this help reduce costs and storage space, but it also promotes collaboration and knowledge sharing.

- Costs related to film and chemicals are eliminated

- Physical storage systems are no longer needed

Non-Destructive Testing Capabilities

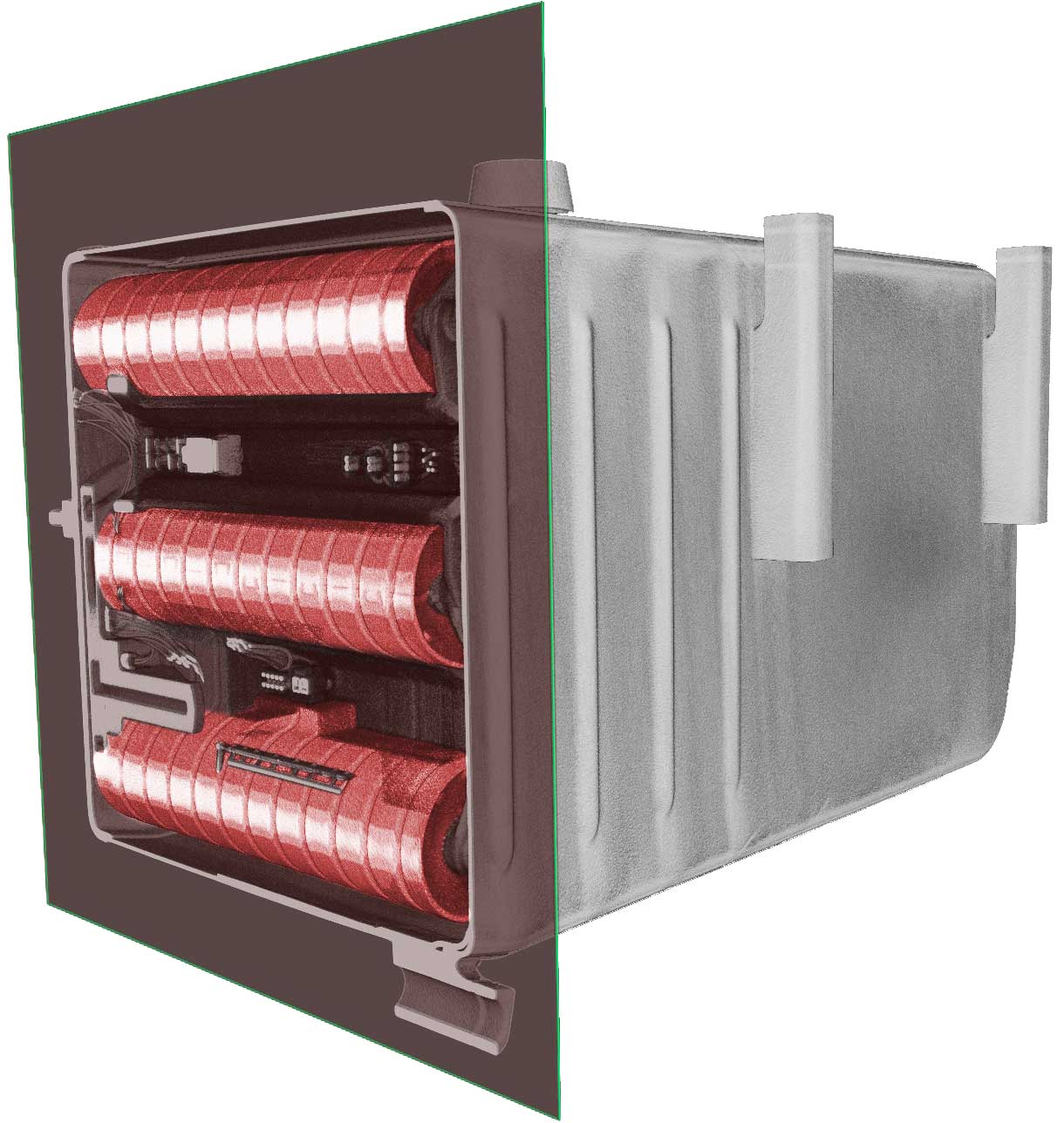

One of the key advantages of digital radiography is that it’s non-destructive. Researchers use high-resolution images to identify defects and anomalies in internal structures without disassembling a product. This saves time and money and reduces the risk of damage to the inspected object. Because digital radiography provides important information about internal structures, it is used extensively for quality control and inspection purposes in many industries, especially aerospace, construction, and manufacturing.

Digital Radiography with North Star Imaging

At North Star Imaging, we specialize in manufacturing advanced X-ray systems for various industrial applications. With our expertise in digital radiography and computed tomography, we provide cutting-edge solutions that meet the evolving needs of industries requiring high-quality imaging for quality control and inspection.

Our efX-DR digital radiography acquisition software is designed to enhance your digital imaging requirements. It integrates seamlessly with our systems and CT software, offering high-performance processing, live measurements, histograms, and a wide range of other features. With efX-DR, you can achieve superior image quality, efficient workflow, and accurate analysis, empowering you to make informed decisions and ensure the integrity of your products and components.

We are available to answer any questions you may have and also offer demonstrations of our products. Ready to learn more? Contact one of NSI’s experts today.