Inspection for Additive Manufacturing: Advancing Quality with CT

Additive manufacturing (AM) continues to transform aerospace and defense production, but it also introduces new inspection challenges that must be addressed to ensure continued safety throughout these industries. Complex geometries, internal channels, and novel defect types demand nondestructive testing (NDT) methods capable of sensing, measuring, and validating the components effectively and efficiently.

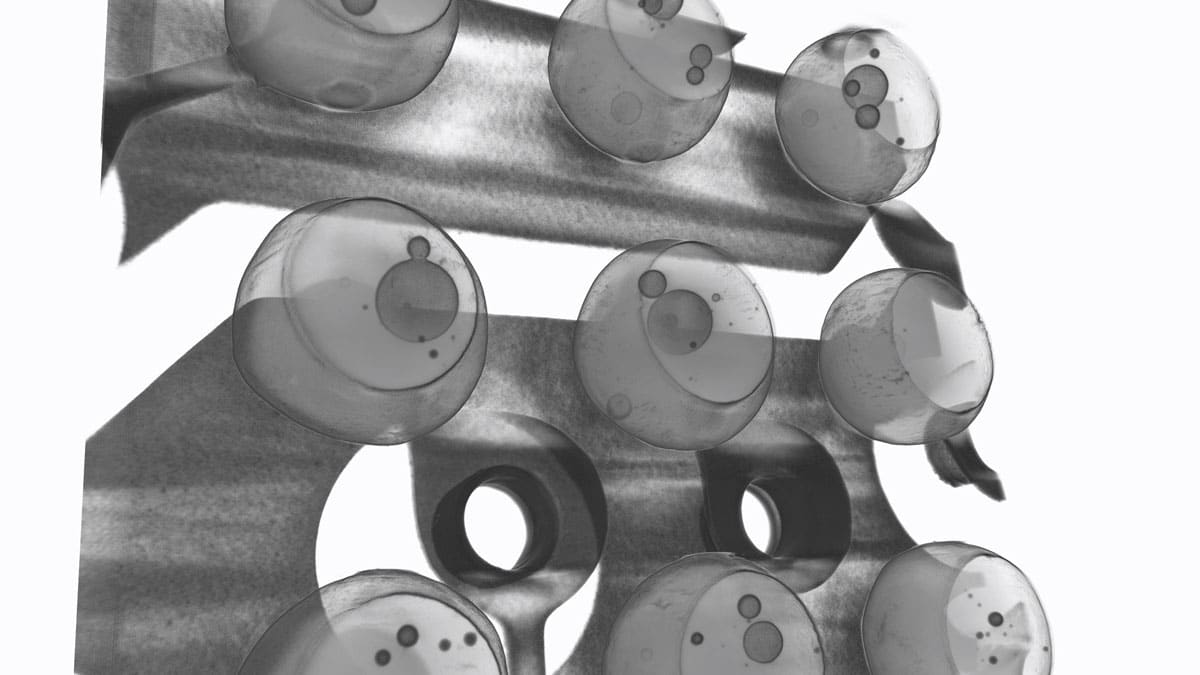

Computed Tomography (CT) has emerged as the leading technique for inspecting 3D‑printed components because it delivers complete volumetric insight.

Meeting ASTM Standards for CT in Additive Manufacturing

Several ASTM standards now guide the deployment of CT for AM inspection, helping engineers ensure process repeatability and qualification:

- ASTM E3166 – Standard Guide for NDT of AM metals using CT

- ASTM F3624 – Practice for Meeting Quality Requirements of Metal AM using XCT

- ASTM E3375 – Data reporting and image quality guidance for industrial CT

- ASTM E1695 – Standard Test Method for CT system performance

As subject matter experts, North Star Imaging’s team contributes and helps write these standards. Therefore, you can rest assured that NSI’s CT systems and software meet and exceed these expectations, offering precision image quality, system stability, and reporting workflows aligned with regulated aerospace environments.

How CT Outperforms Other Methods in AM

Ultrasonic, PT, and radiography can detect certain indication types—but none can capture the full 3D complexity of additively manufactured parts.

CT provides:

- True volumetric inspection of lattice structures, internal channels, and multi‑material builds

- Accurate defect detection for porosity, incomplete fusion, inclusions, and lack‑of‑bond

- High‑resolution visualization and metrology for geometric validation

- Repeatable data critical for qualification and production workflows

With these complex materials, CT’s capabilities far outshine other methods but with any method is it of the utmost importance that they be executed correctly. Understanding the types of defects, coupled with the ideal set up for your given material and component geometry is key. Having a team behind you to help you get started and along the way can be the difference between repeated testing, or worse missing something, and a successful repeatable process. We are here to help.

Key Applications of CT in Additive Manufacturing:

- Defect Detection & Analysis: Identifies voids, porosity, and lack of fusion in metal and polymer AM parts.

- Melt/Fusion Analysis: Assesses material density and distribution to ensure proper fusion and strength.

- Wall Thickness Measurements: Detects inconsistencies in wall thickness, especially in critical aerospace and medical components.

- Dimensional Accuracy Checks: Compares scanned data against CAD files or known measurements to ensure tight tolerances.

- Failure Analysis: Helps manufacturers understand failure modes without destructive testing, preserving costly prototypes.

- Process Simulation Support: Generates precise data for software modeling, improving process efficiency.

- Surface Texture Analysis: Surface texture is a critical performance parameter in AM—particularly where fatigue, aerodynamics, or sealing surfaces are involved. NSI systems enable high‑fidelity surface extraction directly from CT volumes, providing engineers with:

- Quantitative roughness metrics

- Comparisons against CAD

- Automated reporting

High-Energy CT for Metal AM Parts

When it comes to inspecting dense materials such as titanium, Inconel, and stainless steel, high-energy CT is essential. Traditional X-ray and lower-energy CT systems may struggle to penetrate these materials effectively. North Star Imaging’s high-energy CT systems and scanning services allow for deep penetration into dense metal parts while maintaining high resolution, making it possible to identify critical flaws in turbine blades, medical implants, and structural aerospace components.

Build Confidence in Every 3D‑Printed Part

As AM adoption accelerates, so does the demand for inspection solutions built for complexity, speed, and reliability. North Star Imaging delivers CT systems, services, software, training, and expertise trusted across regulated industries.

Ready to improve reliability in your AM program?