Advanced CT X-ray Solutions for Military Munitions and Ordnance Inspection – Keeping Our Military Safe

Military safety is dependent upon consistent assurance of munitions reliability and safety. Even microscopic defects or assembly inconsistencies can lead to catastrophic failures in the field. Computed Tomography (CT) X-ray technology has emerged as a critical tool in the nondestructive testing (NDT) or scanning of a wide range of military components including small-caliber and large-caliber ammunition, solid-fuel rocket motors, composite overwrapped pressure vessels, energetics/explosives, intercontinental ballistic missiles (ICBMs), and fully integrated ordnance systems.

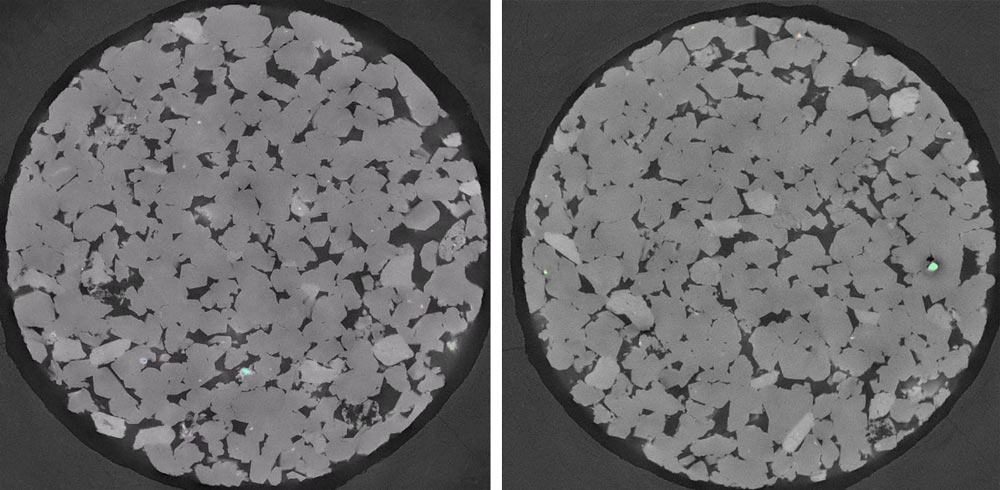

CT scanning also provides an unparalleled view inside cartridge cases, shells, grenades, detonators, fuses, and warheads without disturbing sensitive energetic materials. The technology detects voids in propellant grains, cracks in casings, incorrect or inconsistent packing densities, misaligned initiators, foreign object debris (FOD), and corrosion-induced thinning, all of which can severely compromise performance or safety.

High-energy CT systems deliver the penetration power needed to scan dense materials such as high-alloy steels, tungsten, and thick composites used in military applications. NSI’s systems are capable of imaging heavy, complex structures while maintaining fine resolution necessary to detect defects from a couple hundred microns down to as small as tens of microns. Particularly, for complex energetics, where traditional visual inspections fall short, High Energy CT’s imaging contrast capabilities can distinguish between metal casings, polymer liners, and energetic fillers in one scan. NSI systems offer high-resolution modes capable of achieving voxel sizes of a few microns, making it possible to verify precision-manufactured components to the strict tolerances required by defense standards.

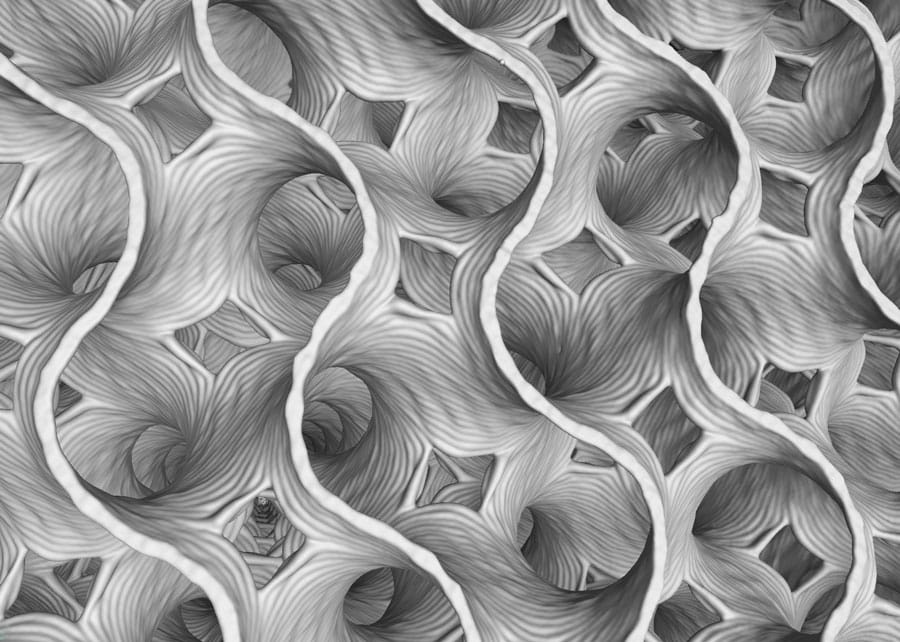

Rocket Motors and ICBMs

Rocket motors and ICBM propulsion systems consist of multi-material assemblies with highly critical bond lines, insulation layers, nozzle throat inserts, and solid-fuel charges. These are notoriously difficult to inspect with conventional methods due to their size and material density.

NSI’s MeVX high-energy CT systems are designed to overcome these challenges by providing deep penetration with minimal beam hardening artifacts. The technology allows for the detection of internal delaminations, improper fuel grain casting, voids, cracks, debonding between insulation and casing, and inclusions that could lead to catastrophic failure under operational stress.

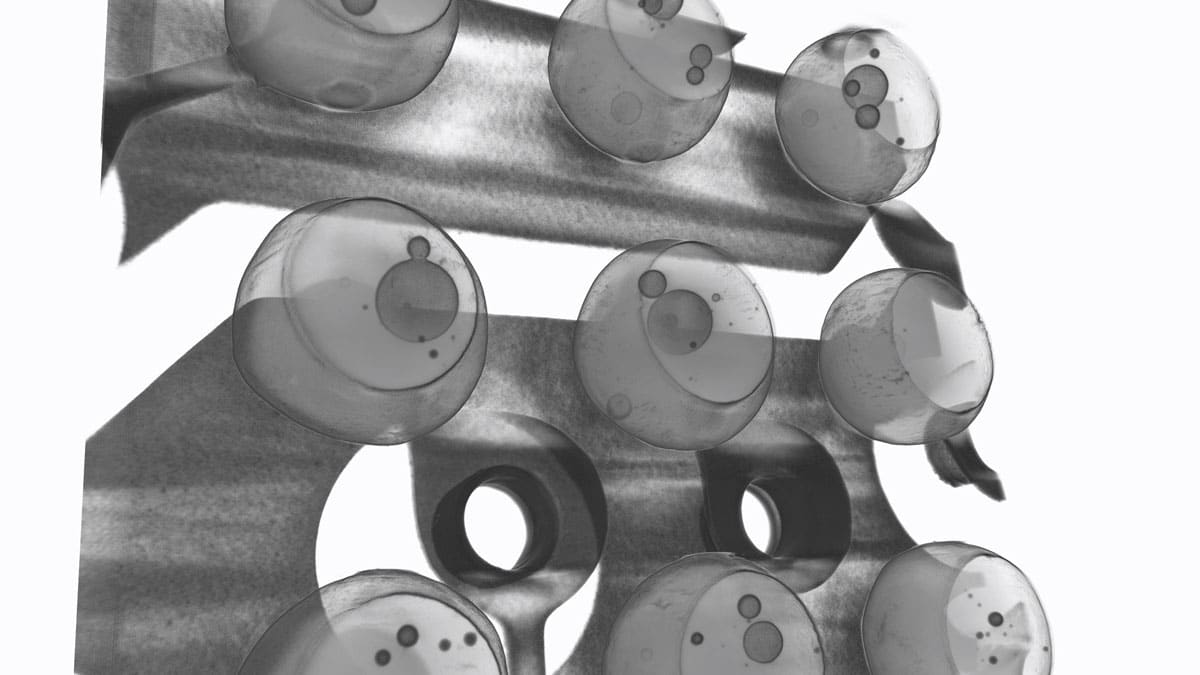

Full Ordnance Systems

The ability to inspect complete assembled systems provides a level of quality assurance unmatched by traditional NDT methods. Full ordnance inspections with CT allow defense engineers to verify the geometric fit-up and alignment of subcomponents, ensure proper assembly sequencing, and detect any mechanical or material anomalies that may not be visible when examining parts individually.

Typical full-ordnance inspections include missiles, torpedoes, guided bombs, cluster munitions, and complex warhead assemblies. NSI’s large-envelope CT scanners, like the MeVX and X7000, accommodate heavy and long components, providing high-resolution imaging over large scan volumes.

The application of automated defect recognition (ADR) with NSI’s efX-ADR software reduces human error and inspection time, enabling consistent and repeatable detection of critical flaws across production lots. This high level of reliability directly supports mission assurance programs and helps maintain the integrity of national defense stockpiles.

Advances in Software Help Ensure Safety Further

CT data can also be used for reverse engineering and dimensional verification of legacy systems or foreign objects when drawings and specifications are unavailable. NSI’s efX-Sim software provides simulation-based scan planning to optimize inspection setups and reduce unnecessary exposure times, protecting sensitive energetics during the scanning process.

NSI’s High-Energy MeVX® CT Systems, coupled with efX® software suite, provides advanced features like virtual slicing, wall thickness analysis, defect segmentation, and automatic defect recognition (ADR) to streamline the inspection process and improve the repeatability of analysis.

Partnering for a Safer Future

In defense sector, where the margin for error is minimal, NSI’s CT systems and expertise offer invaluable support to defense manufacturers and agencies. Through precise imaging and analysis, they help ensure that every component performs as intended, ultimately protecting lives and safeguarding national security.

Our turnkey CT systems, as well as our configurable CT systems and application support teams tailor solutions to meet the rigorous demands of defense projects, from R&D and failure analysis to final qualification and life-cycle extension inspections.

NSI is federally licensed to handle and has decades of experience safely inspecting Class 1.3 and 1.4 explosives using proven, specialized containment and scanning protocols. NSI is ISO 9001:2015 certified,

ISO 14001:2015 certified, ITAR registered/compliant, ASTM compliant, DOD 4145.26-M Compliant, and has ASNT & NAS 410 certified imaging professionals.

For more information on NSI’s CT solutions for military applications, visit our Military and Defense page.