More Efficient Automotive Manufacturing Inspection with High-Energy Computed Tomography

With the rapid technological advancements in the automotive industry, demand for innovative inspection solutions has become paramount. One such breakthrough is high-energy computed tomography (CT), revolutionizing the inspection process by providing unparalleled detail and insight into complex assemblies.

Low-energy x-ray CT imaging (sub-600kV) has been a common choice for industrial parts. Typically, capable of resolutions in the single-digit micron range, this granular detail easily shows fine features such as the individual layers in the latest batteries. The shift towards EVs, with their intricate battery modules and large electric motors, underscores the need for more sophisticated inspection capabilities to meet increased industry standards. These large and complex assemblies require a much higher energy source to penetrate its dense composition.

Utilizing a state-of-the-art 9MeV linear accelerator (LINAC), companies are able to achieve unprecedented levels of accuracy and clarity in their scans, resulting in higher image quality with reduced noise, reduced scatter and beam hardening artifacts that, negatively impact the image fidelity of a part.

Another key advantage of high-energy CT is its ability to inspect fully assembled components, such as large electric motors, battery modules, and transmissions, without the need for disassembly. This approach not only saves time and resources but also minimizes the risk of damage to delicate components. In a single scan, materials with vastly different densities, (ex: aluminum, steel, copper, plastics, epoxy) can be visualized with exceptional clarity, providing a comprehensive view of the entire assembly. Additionally, battery modules up to 36 inches wide are able to be scanned at certain facilities in the U.S.

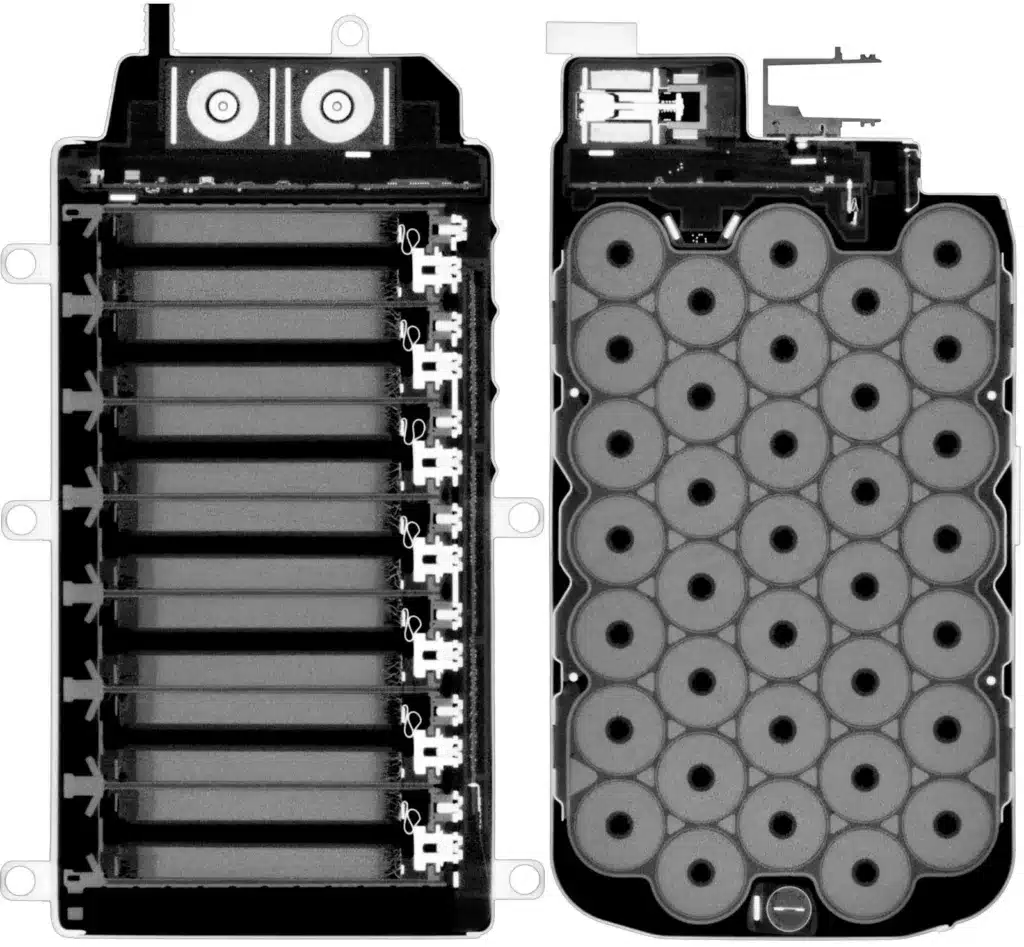

The image below clearly shows us the pure latitude of materials we can accurately represent with High Energy. You can see here the plastic battery case along with steel and other higher density materials. Notice there are not streaking artifacts from the high density into the low density.

The advantage of efficiency for not having to disassemble modules is apparent in this example. The high energy CT scan, when coupled with advanced software and experienced CT subject matter experts, allows for clarity and accuracy without disassembly. The image below shows the range of materials in the whole module. We can see here in this one image everything from lead or tin solder, PCB board substrate, copper bus’s, plastic battery case’s, steel screws, steel outer module case, lithium-ion battery cells, copper wires, and among other materials.

As technology continues to evolve, so too will the capabilities of high-energy CT. With ongoing advancements in imaging technology and data analysis techniques, the future of manufacturing inspection looks brighter than ever. By embracing innovation and investing in state-of-the-art solutions like high-energy CT, manufacturers can stay ahead of the curve and unlock new possibilities in quality assurance and product development.

In conclusion, high-energy computed tomography represents a quantum leap forward in the field of manufacturing inspection. With its ability to penetrate dense materials, image materials of various densities without disassembly of modules, detect hidden defects, and provide comprehensive visibility across the entire production chain; high-energy CT is poised to revolutionize the way products are designed, produced, and inspected. As industries continue to evolve and embrace new technologies, the role of high-energy CT will only become more indispensable, driving innovation, efficiency, and quality in manufacturing processes worldwide.

Interested in learning more? Contact us or check out our full length article in OneStopNDT’s NDT Trends May 2024 Issue.