Industrial Micro-Computed Tomography Uncovering History

Industrial Micro-Computed Tomography for archaeologists, arts experts, museums and more. A very powerful and non-destructive technique to examine the inside of an object in 3 dimensions.

The increase in capabilities of CT has led to industrial CT scanners being used more often and in more ways than ever before.

Within the different worldwide NSI Inspection Service labs, we have seen a tremendous growth of CT scanning requests coming from various industries and research labs (for instance, in fields such as aeronautic/aerospace, automotive, medical devices, defense, dental, food,… to name a few). The companies we work with use the high potential of CT technology to help develop new products, control the quality of their production, qualify and optimize new production processes or new materials, non-destructively expect defective components, and more.

Something very interesting, although very different from the “usual” industrial applications – such as non-destructive testing or measurement – is the increasing number of CT scanning requests we had in Europe, coming from archaeologists, arts experts, and museums. In this article, I would like to take the opportunity to highlight the many benefits of 3D CT scanning, focusing on one of those very interesting applications: a Merovingian belt buckle that has been CT scanned right after collection from a sepulture, still melted in the clay.

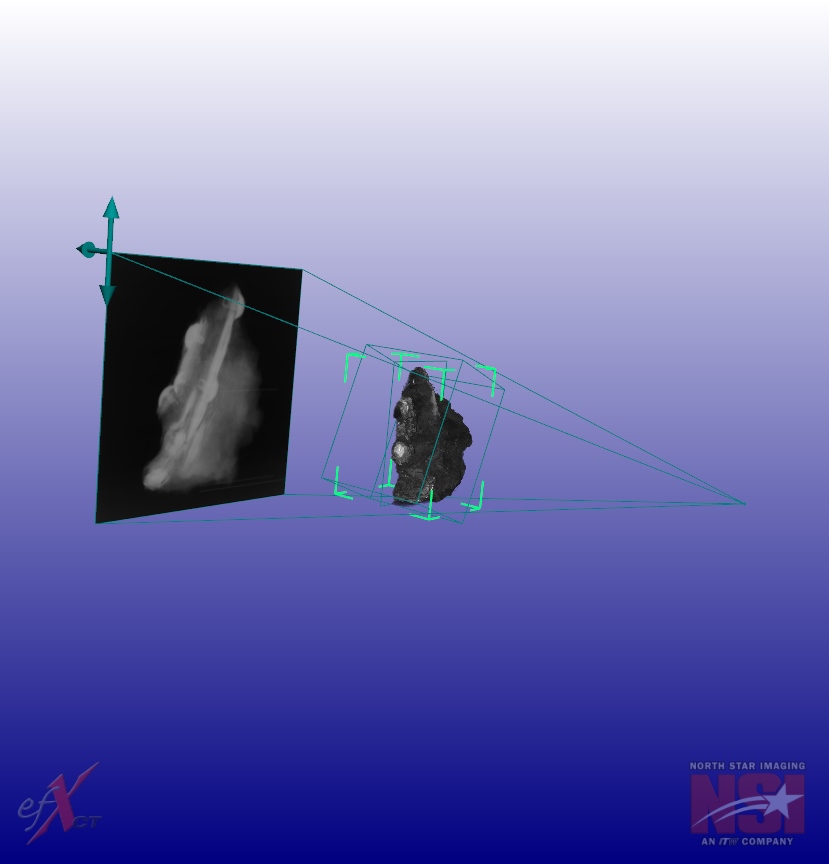

As a brief reminder, an industrial CT system uses basically three principal components: an X-ray Tube (on the right of the picture), an X-ray Detector (on the left). The object to be inspected stands in between, on a rotational stage.

Everything is enclosed in a radiation shielding Steel/Lead/Steel cabinet. This allows the use of the system in a public environment without any additional safety concerns.

Adjacent to the enclosure is a computer workstation, consisting of a 2D X-ray console for the set up and acquisition steps, and a 3D CT supercomputer workstation for volume reconstruction and 3D visualization.

Acquisition of the Merovingian belt buckle

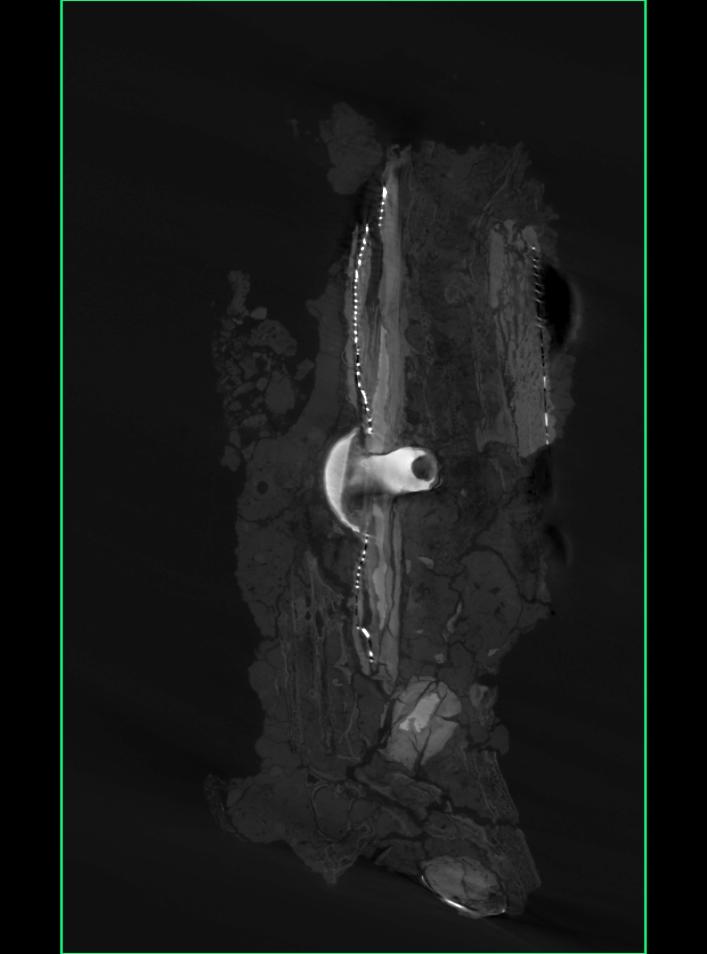

A great benefit of CT is that it is non-destructive. It doesn’t heat the specimen. It works with any surface, shape, color or material (up to a certain density and/or thickness penetrable with X-rays). In this instance, it was possible to scan the sample exactly as it was collected in the sepulture, still melted in the clay!

In operation, CT generates X-ray photons that either travel through the object or are attenuated by it. The photons that penetrate the object enter the imaging detector, carrying with them detailed information (see image below). The degree of photon attenuation depends on the amount of energy applied and the thickness or density of the material that the photon pass through.

A modern high-end CT scan consists of taking several 2D X-ray images around the object, preferably covering 360 degrees (complete rotation).

On that specific sample, 1800 images have been acquired (1 image every 0.2 degree). Each image is 8 Megapixels and is also averaged and filtered to reduce noise. The 2D digital images taken during this step are saved directly into a single folder which will be used in the next step of the CT process.

Reconstruction and Visualization

Once the acquisition process of the CT scan is completed, CT calibration and CT reconstruction algorithms are used to reconstruct the 3D CT volume. These 3D images are made of Voxels (three dimensional Pixels), and with the use of visualization software the 3D volume can be manipulated in real time. Now it is possible to slice through anywhere inside the object, inspect and look for key features and take accurate measurements.

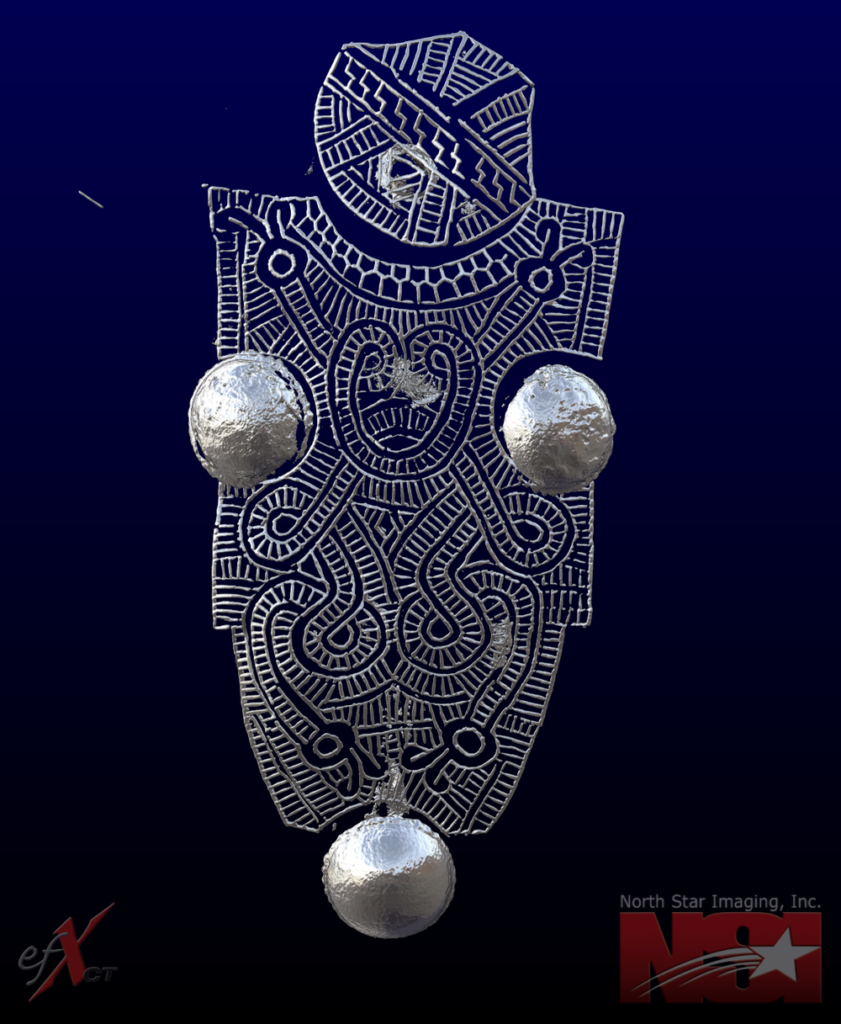

The 3D CT reconstruction, which is a volume made usually of several millions of Voxels (3D pixels), can also be transformed to a surface model.

As already explained, the X-ray photon attenuation is different, depending on the thickness or density of the materials. Thus, a threshold value of radiodensity can be chosen by the operator and set using edge detection image processing algorithms. From this, a 3-dimensional model (a polygon mesh) is generated and displayed on screen.

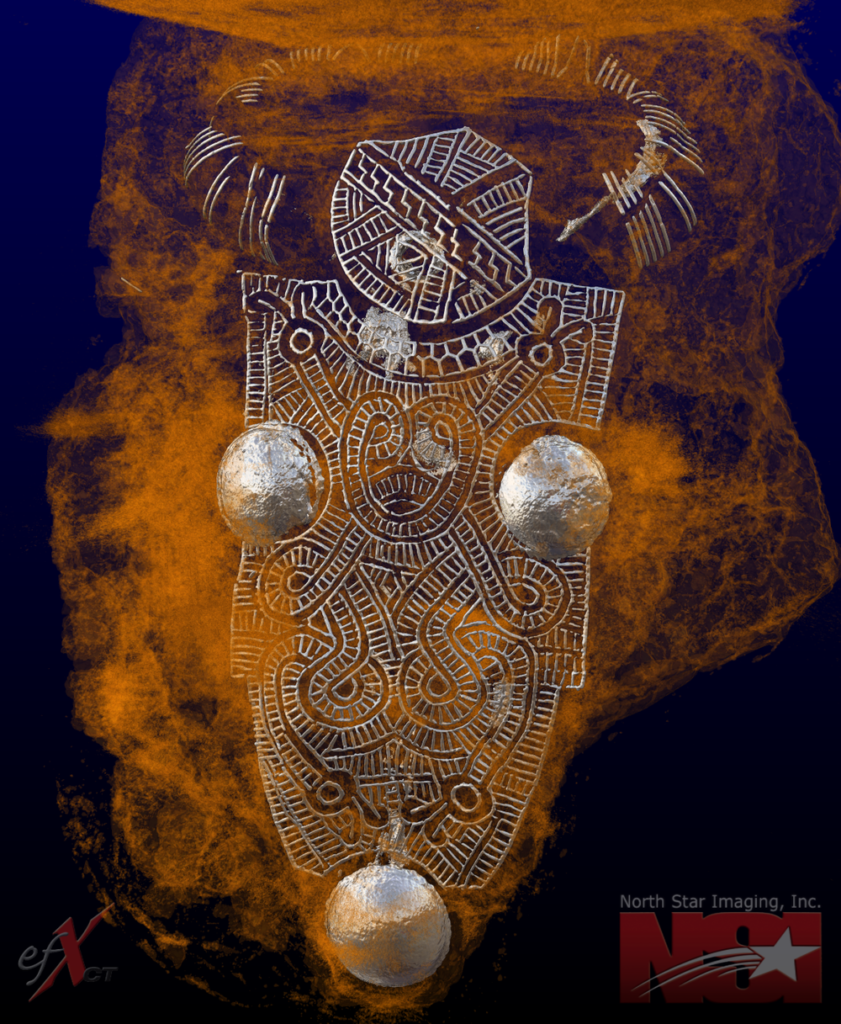

Multiple models can be constructed from various different radiodensity thresholds, therefore allowing different colors to represent each component of an assembly.

In this specific application, the clay and the metallic belt buckle are represented in different grey colors. After segmentation and surfacic reconstructions, those 2 components can be displayed in 2 different colors.

It is also possible to segment the histogram, so that only one component is displayed, for instance, the metallic belt buckle, which is of higher density.

The resolution of the 3D surfacic model depends on the number of Voxels generated from CT reconstruction, which also depends on the size of the object that is scanned. The resolution is excellent. Industrial micro CT scanners offer image resolutions that can be up to hundreds of times higher than what is used in the medical field. Typically, those 3D models are composed of thousands of polygons up to 50 million polygons.

The output format (points cloud, STL,…) is also compatible with rapid prototyping machines, and in most cases the polygon mesh generated by the CT system can be used without modification.

The model can then be 3D printed, thus opening the door to many new applications!

Over the years, the industrial CT technology has rapidly improved and has become a very competitive technology for 3D scanning. Having very accurate internal information of an object, without destroying it, along with the ability to get a clear understanding of how well the object has been preserved before starting any time consuming and costly restoration is entirely unique to CT.

There are no shaded zones, it works with any kind of shapes and surfaces, and almost any material (to the extent that the density and/or thickness allows a good X-ray penetration). There is no post-processing work – or very few – needed and the resolution both internally and externally is excellent.

All in all, 3D CT is the only technology capable of achieving such performance, and it is now accessible for most industries, research labs, archaeologists, arts experts, museums and much more.