Automated X-ray CT Scanning with RobotiX™: Raising the Bar in Aerospace, Automotive & Medical Manufacturing

In today’s advanced manufacturing landscape, inspection can’t just be accurate—it must be automated, fast, and scalable. North Star Imaging’s RobotiX™ systems meet this challenge by integrating industrial robots with digital X-ray machines, industrial CT scanners, and powerful software into a fully autonomous inspection solution.

From turbine blades to pacemakers and EV battery modules, manufacturers across aerospace, medical device, and automotive sectors rely on RobotiX systems to improve throughput, ensure safety, and minimize downtime.

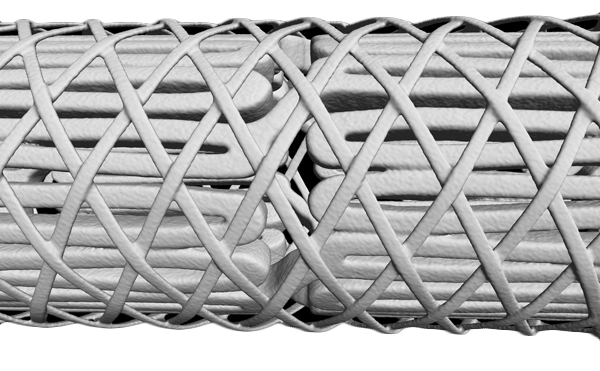

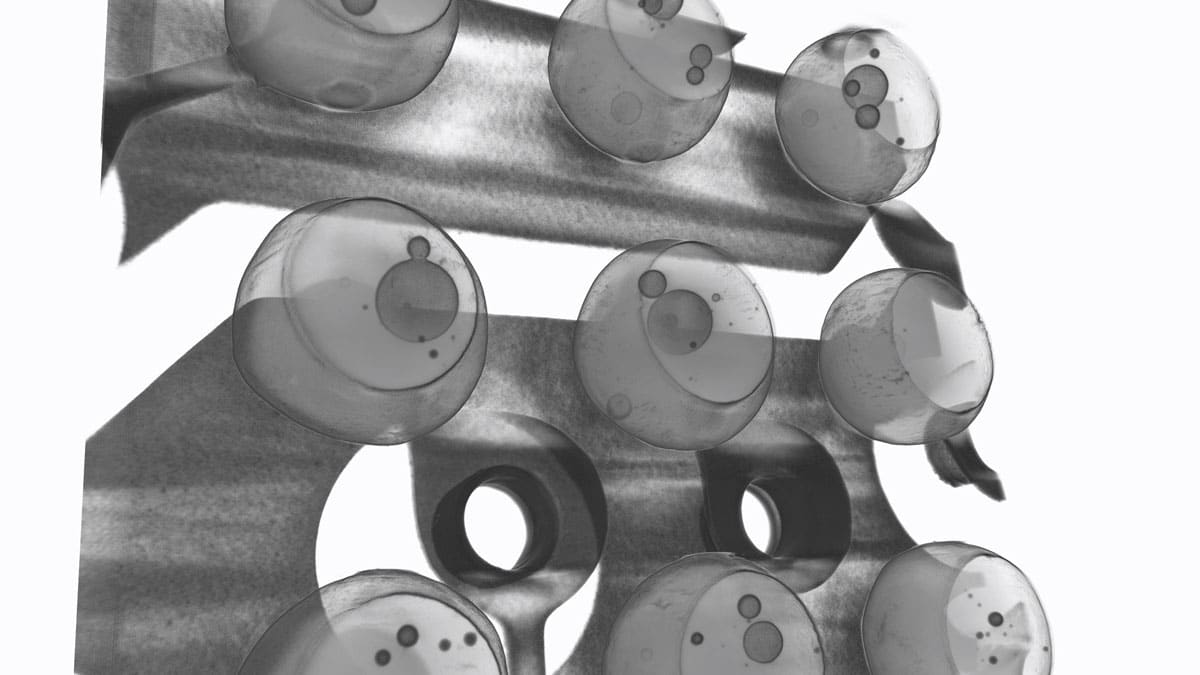

Aerospace: High-Precision, High-Stakes Inspection

When it comes to parts like turbine blades, fuel injectors, and composite components, failure is not an option because it is costly and jeopardizes public safety. RobotiX systems are used in aerospace to perform industrial CT scans that reveal internal flaws such as porosity, cracks, and inclusions—without disassembling or damaging parts.

Using dual RobotiX systems (see image below), two robot arms coordinate in real-time to position parts or detectors, eliminating the need for complex fixturing and reducing door cycles.

Read more in NSI’s aerospace application notes

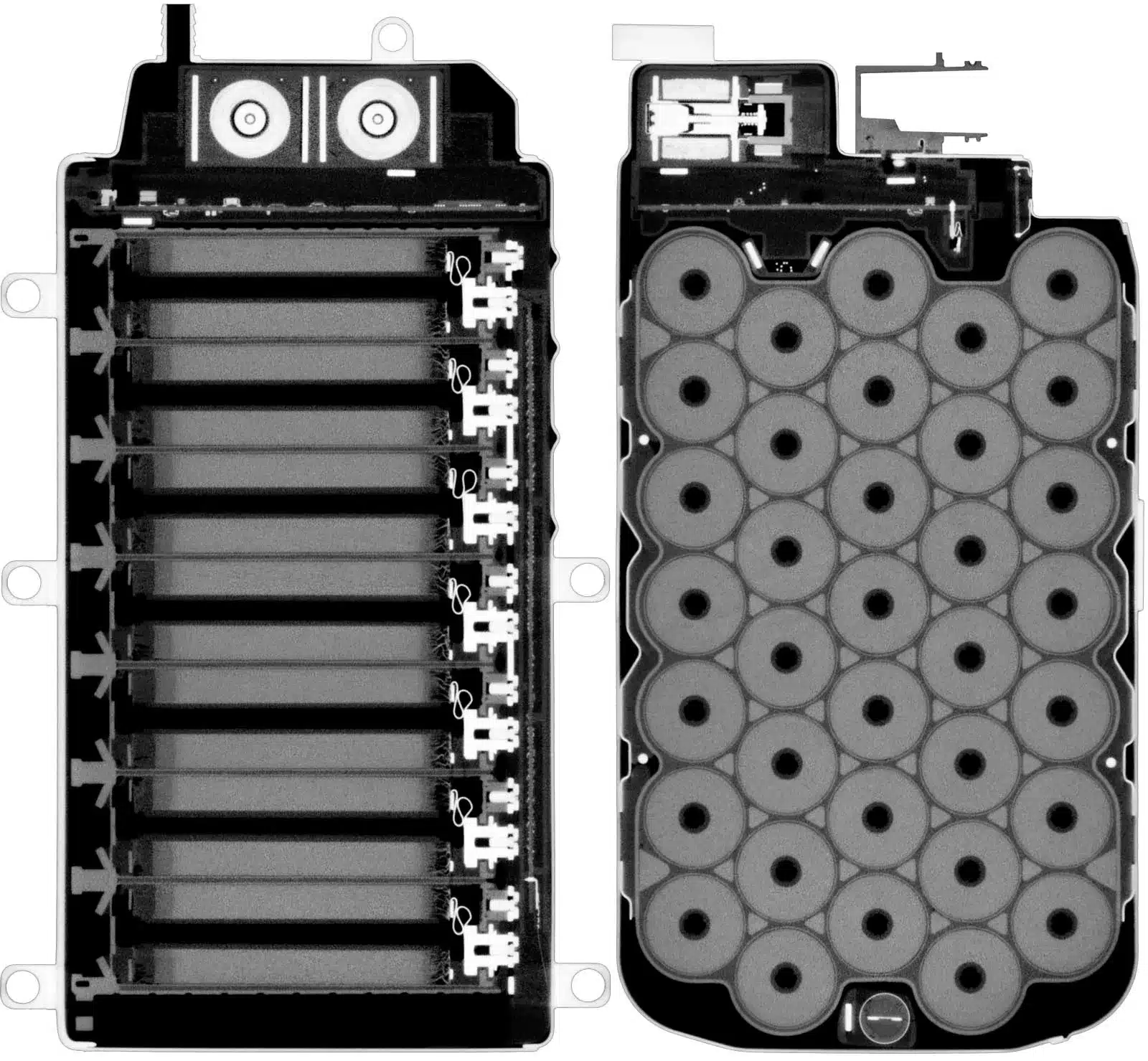

Automotive: Powering Up EV Battery Quality

The shift to electric vehicles demands fast, reliable inspection of batteries, modules, and electronics. RobotiX systems offer automated X-ray inspection and 3D CT reconstruction of battery packs and high-voltage components—verifying welds, internal connections, and detecting contaminants.

NSI’s X5000 and X7000 systems paired with RobotiX loaders can scan large volumes of parts with minimal operator intervention, supporting full production-line integration.

Explore NSI’s EV battery inspection capabilities

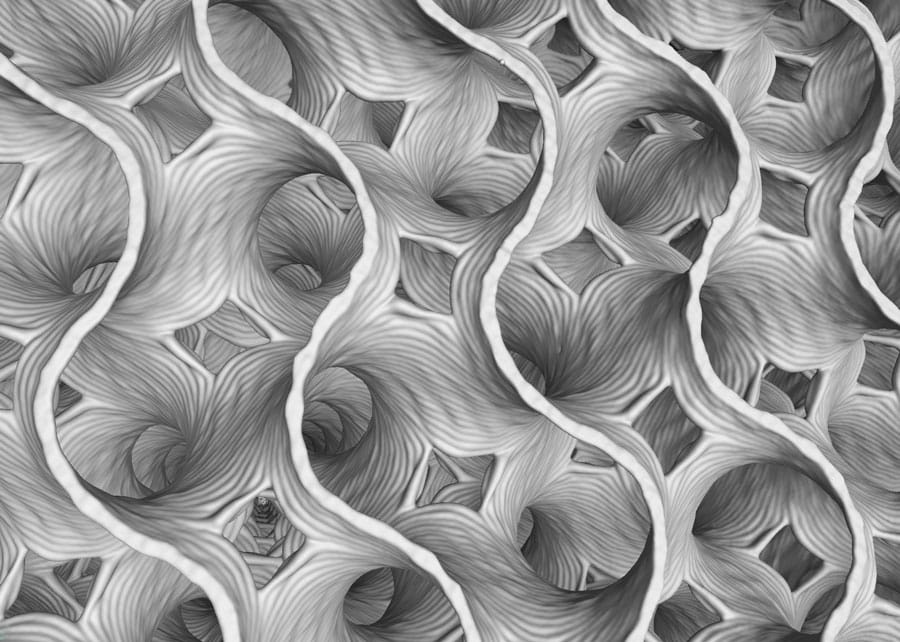

Medical Devices: Scanning the Microscopic with Confidence

Inspection of stents, pacemakers, filters, microbatteries, and drug delivery systems requires submicron resolution and traceability. RobotiX allows automated part loading, scanning, and analysis, ensuring repeatability without subjecting operators to radiation.

NSI’s high-resolution X25 system and efX-CT software enable ultra-detailed scanning with integrated defect recognition. ADR (Assisted Defect Recognition) shifts the burden from humans to computerized systems, allowing technicians to focus on analysis, not repetition.

Learn more about ADR software

Why RobotiX? The End-to-End Advantage

What makes NSI’s automated X-ray systems stand out?

Autonomous Operation

Automatic part loading/unloading and repositioning using robotic systems, guided entirely by NSI’s efX-DR software.

End-to-End Workflow

From robotic motion to CT reconstruction to defect recognition—everything happens within one interface using NSI’s production modules.

Versatility & Configurability

Available on systems ranging from X25 to X7000, and configurable for batch inspection, high energy CT, or small-volume R&D labs.

Data-Rich Results

Integrated CT metrology tools and automated defect logging help your inspection teams meet regulatory requirements across sectors.

Training

Subject Matter Experts provide training and support to help guide you through your training as well as your toughest challenges to optimize your productivity.

PM and Service

Comprehensive preventative maintenance and quick response times for service calls keep production moving.

Explore NSI’s inspection and scanning services if you want help with your first projects.

Built for the Future

As labor markets tighten and demand for throughput grows, automation in NDT is no longer optional—it’s essential. RobotiX systems from North Star Imaging offer a complete industrial x-ray inspection system with unmatched flexibility and performance.

Whether you’re inspecting 200 pacemakers or 2,000 EV battery packs—RobotiX delivers accuracy at scale.

Contact North Star Imaging to schedule a RobotiX demo or system consultation.