North Star Imaging Asia Office

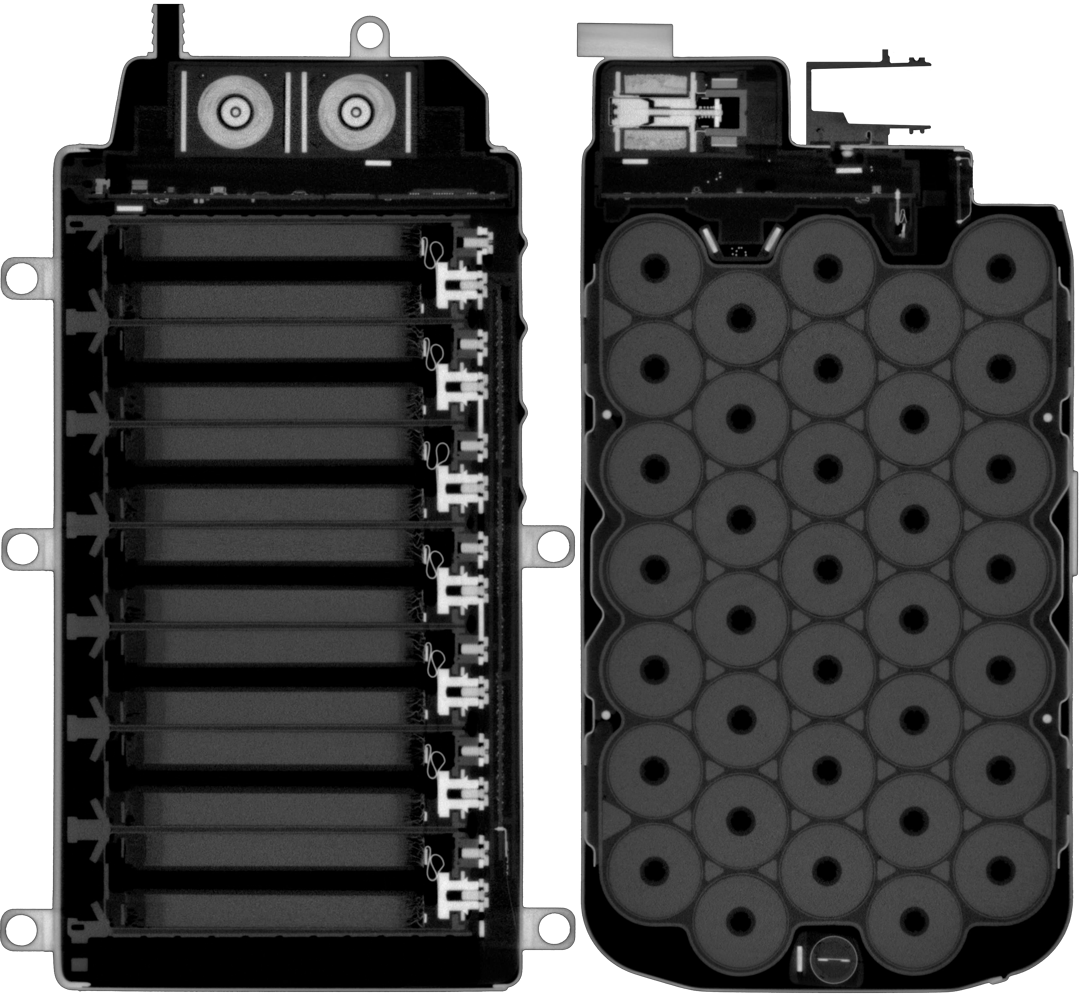

Our North Star Imaging Asia office, located in Suzhou, China features a state-of-the-art X-ray and Computed Tomography inspection services laboratory. Parties interested in digital X-ray and Computed Tomography can visit this facility to test their samples on the versatile X5000 which has a wide scanning range, applicable for scanning small to large items.

North Star Imaging offers advice and support for existing and new customers to develop application specific solutions and supply inspection services.

Our China office service area includes these locations and their surrounding suburbs:

Beijing

Hangzhou

Shenzhen

Chengdu

Guiyang

Shijiazhuang

X-ray & CT Inspection Service

North Star Imaging provides nationwide 2D Radiography and 3D Computed Tomography services for your X-ray inspection needs. Our X-ray and CT Technology gives insight into virtually all materials from wood to plastics to metals in industries including construction, automotive, medical devices, pharmacy, electronics, aerospace, and beyond.

Our Lab Provides:

- 2D real time digital radiography

- 3D micro computed tomography

- Internal measurements

- 3D CAD comparisons

- Void and/or porosity analysis

- Surface reconstructions for reverse engineering

- Finite Element Analysis

- Failure analysis

- And much more..

X-Ray Inspection Process

Consult

Consult our application specialists to develop a plan of action.

Ship

Ship your product to any of our worldwide locations.

Scan/Data

Rotate, virtually cross section, and measure your part with our viewing software.

Results

Meet virtually or visit our facility to answer your questions.

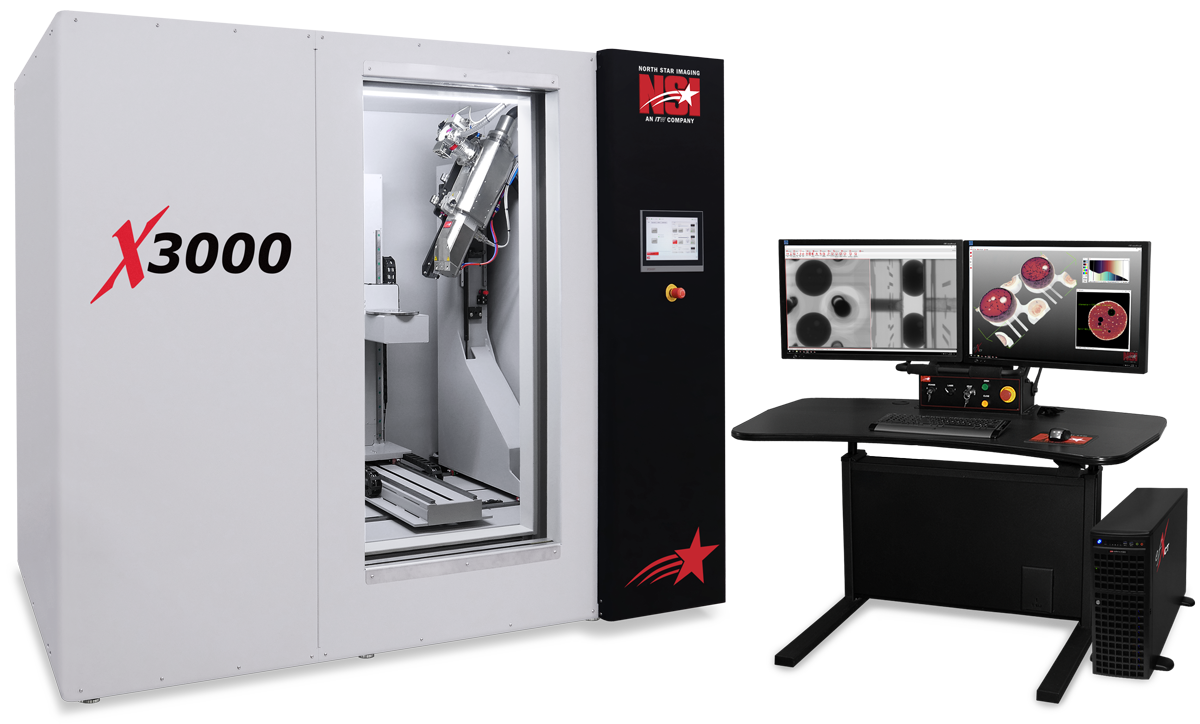

2D X-ray Digital Radiography and 3D X-ray Computed Tomography Inspection Systems

North Star Imaging offers a full range of 2D digital radiography X-ray inspection systems, 3D X-ray computed tomography inspection systems, high energy X-ray systems, and X-ray metrology systems. All our systems are modular, giving you the flexibility to select the best combination of features for your specific application.

Our X-ray scanners are designed with superior resolution and accuracy while maintaining an easy to use interface. Whether it’s high speed 3D scanning, failure analysis, or reverse engineering, our systems are built for efficiency and repeatability to ensure your components function safely and correctly each and every time. Ranging in size from compact to large vault options, you can seamlessly acquire full internal and external details of your components. From new product development to process development to quality control, X-ray technology saves time and money throughout the product life cycle. No nondestructive testing challenge is too small or too large for our attention.