Webinar Series – A Journey Through Advanced Manufacturing

Leveraging State of the Art Design, Simulation, Build, Inspection, and Test to Bring Next Generation Products to Market

View this 6 part on-demand webinar series

WHAT TO EXPECT

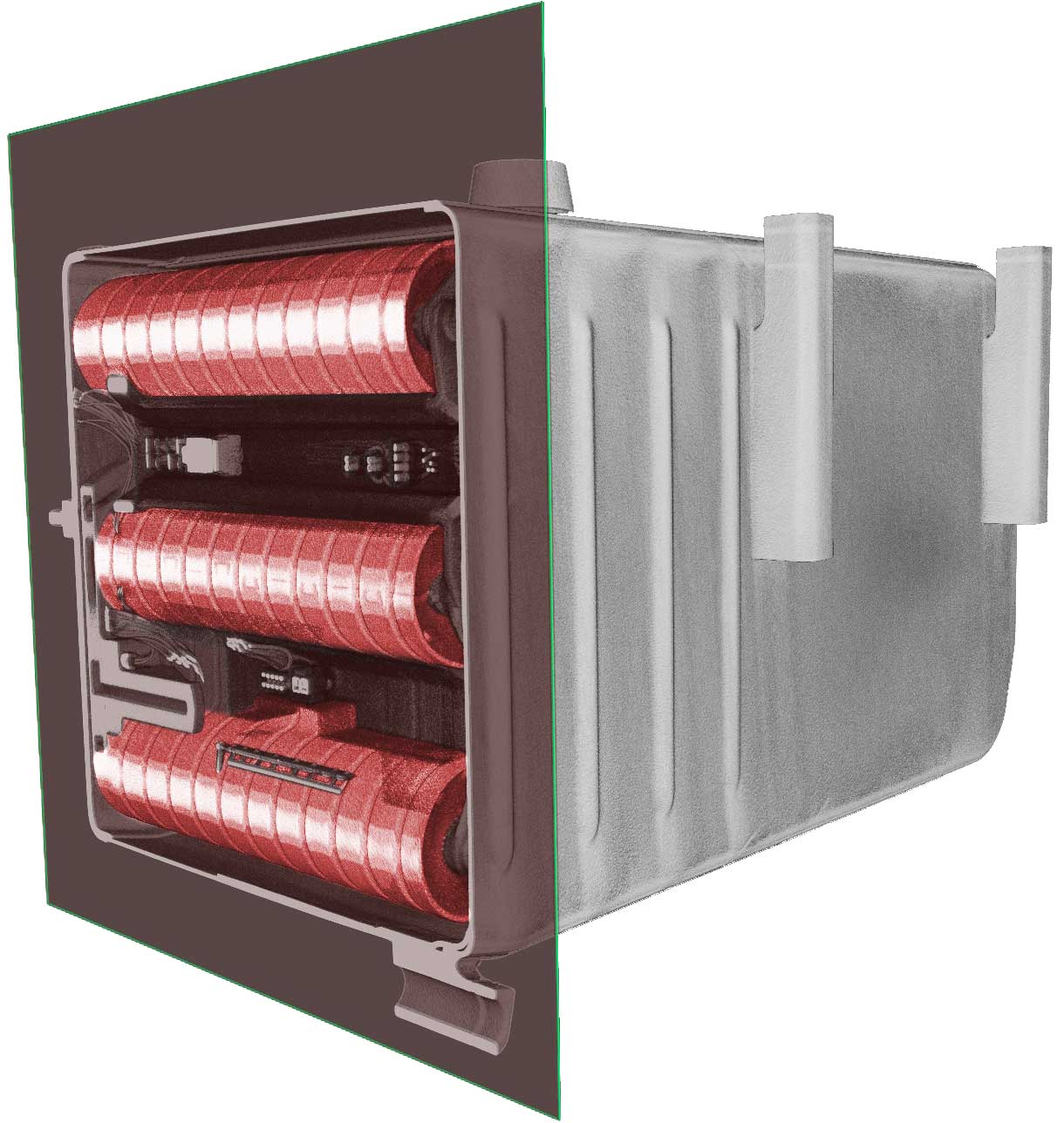

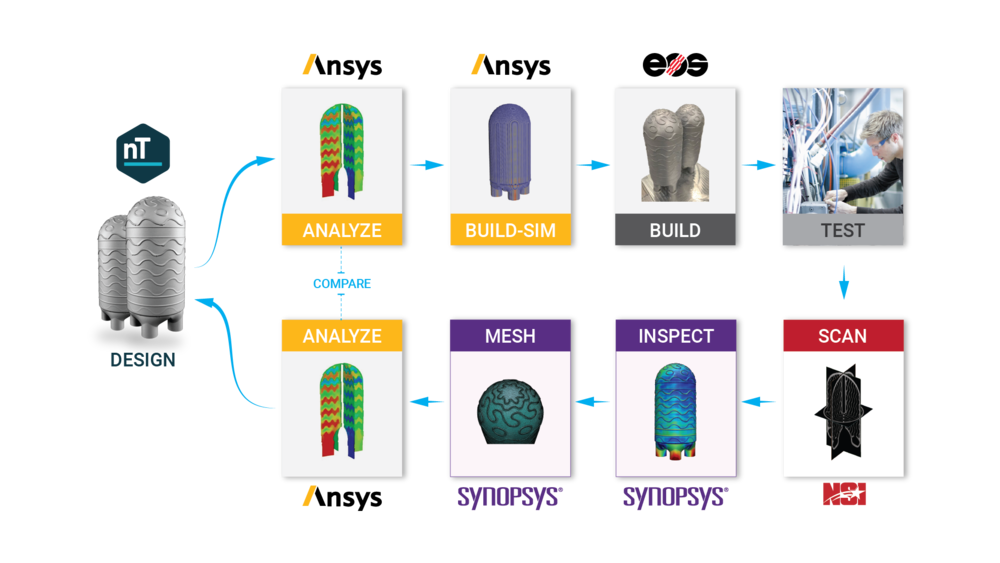

In this unique and virtual collaborative project, multiple industry leaders took on the challenge to develop a clean slate rapid design of a traditional heat exchanger leveraging their most advanced capabilities that their companies offered.

As a result, the new design is 80% lighter, 40% smaller in form-factor, and 10x more efficient in heat transfer than conventional technology. The agility of the team’s participants enabled the entire process to be completed in less than 4 months. This included all the critical steps of design, simulations, inspection, and testing. As part of this webinar series you will learn how you can leverage common and commercially available solutions to replicate similar advancements in your own product development.

WEBINAR 1 – ADVANCED MANUFACTURING REVOLUTION – LEVERAGING A NEW PARADIGM FOR GROWTH

This session will cover:

- nTopology, Ansys, EOS, North Star Imaging (NSI) and Synopsys, collaborated remotely in this virtual innovation project.

- The webinar will highlight the key technologies necessary for rapid innovation and execution of this project using advanced manufacturing technology. Project Logistics, timelines and ROI related metrics will be highlighted.

- Extract maximum value from existing design, simulation and inspection tools.

Who is this for: Technology leaders and managers

Speakers: Ryan O’Hara (nTopology), Sunil Acharya (Ansys), Kerim Genc (Synopsys)

WEBINAR 2 – DESIGN PROCESS WITH SIMULATION

This session will cover:

- nTopology and Ansys will discuss how to generate dense thermally efficient heat exchanger designs

- Leverage state of the art design and simulation tools to produce higher performing heat exchangers in volume constrained applications

- Demonstrating how the next generation of implicit geometry representations can be used to drive the future of heat exchanger designs and gains in heat exchanger performance.

Who this is for: Designers and simulation analysts and their managers

Speakers: Maiki Vlahinos (nTopology), Walter Schwartz (Ansys)

WEBINAR 3 – MAY 13TH – SIMULATION TO REALITY: USING ADDITIVE MANUFACTURING SOLUTIONS TO OPTIMIZE AND PRINT

This session will cover:

- Ansys and EOS will discuss the build process optimization and the successful printing in the first attempt.

- The Additive Manufacturing simulations used to optimize the build process and support design.

Who this is for: Designers and Additive Manufacturing engineers and their managers

Speakers: Mohammad Masoomi (Ansys), Jon Spragg (EOS)

WEBINAR 4 – MAY 27TH – CT SCANNING OF THE PART AND IMAGE-BASED INSPECTION

This session will cover:

- NSI and Synopsys will discuss the CT scanning process and how the 3D image data was used for Inspection

- Complete image processing including defect detection, CAD comparison and porosity analysis.

Who this is for: Machine operators, Quality Control engineers and their managers

Speakers: Brett Muehlhauser (NSI), Thomas Spirka (Synopsys)

WEBINAR 5 – JUNE 10TH – REVERSE ENGINEERING AND VALIDATION

This session will cover:

- Synopsys and Ansys discusses the process of reverse engineering of image data.

- Efficiently convert image data into multi-domain and error free volumetric FE meshes.

- Comparison of heat exchanger performance for the as-built vs as-designed models.

Who this is for: Analysts, Quality Control engineers and their managers

Speakers: Thomas Spirka (Synopsys), Sunil Acharya (Ansys)

LIVE PANEL DISCUSSION – JUNE 24TH – NTOPOLOGY, ANSYS, EOS, NSI, SYNOPSYS, AND STRESS ENGINEERING SERVICES

This session will cover:

- Expert Panel discussion of the entire workflow and implications on mass-production

- What could go wrong? Step-by-step challenges.

Who this is for: Everyone interested in implementing Additive Manufacturing within their organization

Panel: Ryan O’Hara (nTopology), Brent Stucker (Ansys), Sunil Acharya (Ansys), Kerim Genc (Synopsys), Jon Spragg (EOS), Brett Muehlhauser (NSI), Matt Sanders (Stress Engineering Services)

Speaker Bios

Brett Muehlhauser, R&D Technical Fellow, North Star Imaging

Brett is a Research and Development Technical Fellow at NSI working to continue the advancement of CT and DR technologies and applications. Brett has been with NSI for 20 years performing R&D, applications engineering, Failure Analysis, writing DR and CT training curriculum and teaching these courses to a global audience. He has worked in the field of Digital X-ray Imaging for over 35 years. Prior to coming to NSI, Brett worked in the aerospace industry for 15 years performing product development, failure analysis and product evaluations. Brett has been an ASNT and NAS 410 Level 3 for the last 35 years and been actively involved in the development of ASTM standards for Computed Tomography and Digital Radiography.

Kerim Genc, PhD, Business Development Manager, Synopsys

Dr. Kerim Genc is the Business Development Manager for the Simpleware Product Group at Synopsys. He joined Simpleware in 2011 as a Technical Sales Consultant and is currently responsible for managing global sales, business development and technical marketing content development.

He received his BS and MS in biomechanics from the University of Calgary and the Pennsylvania State University respectively and completed his PhD in Biomedical Engineering at Case Western Reserve University looking at countermeasures to spaceflight induced bone loss and fracture risk.

Brent Stucker, PhD, Distinguished Engineer, ANSYS

Dr. Brent Stucker is a Distinguished Engineer in Additive Manufacturing (AM) at Ansys. He is the co-founder and former CEO of 3DSIM, acquired by ANSYS in November, 2017. Dr. Stucker has been a leading researcher and industry expert in additive manufacturing for almost 30 years. Dr. Stucker was the founding chairman of ASTM International Committee F42 on Additive Manufacturing Technologies, and was elected to the ASTM International Board of Directors in 2015. He has received numerous AM awards. Dr. Stucker holds numerous patents, has authored and co-authored over 200 technical publications on AM, and has presented over 500 technical talks.

Mohammad Masoomi, PhD, Application Engineer II, ANSYS

Dr. Mohammad Masoomi is a Mechanical Application Engineer with a focus on Additive Manufacturing in ANSYS. Mohammad has research experience with influence of AM process parameters on mechanical properties of the fabricated parts and development of numerical method for thermal history prediction. Mohammad’s research has been published in 14 journal and conference publications. He holds a Ph.D. from Auburn University.

Jon Spragg, Senior Applications Engineer, EOS North America

Jon Spragg is a Senior Applications Engineer for EOS North America, where he is responsible for training customers on EOS’ newest industrial 3D printing equipment (EOS M 400-4 SES L and EOS M 300-4) with and without monitoring capabilities.

Jon began his additive manufacturing career at DSM Sonia in 2005 as an applications technician in New Castle, DE. In 2012, he was hired by Integra, working as an SLA applications engineer. EOS acquired Integra later that year and he has been training new and existing customer metal applications ever since. Jon specializes in the EOS monitoring suite software (EOSTATE OT and MPM).

Jon has a chemistry degree from The College of Wooster in Wooster, Ohio.

Ryan O’Hara, PhD, Technical Director of Aerospace and Defense, nTopology

Dr. Ryan P. O’Hara is currently serving as the Technical Director for Aerospace and Defense at nTopology, Dr. O’Hara joined nTopology in April 2019 after 20 years of military service in the United States Air Force as a Developmental Engineer. His technical focus is on the application of Mechanical Structures and Structural Dynamics to Aerospace Systems. Areas of interest include turbine engines, laminate composites, meta-materials, and additive manufacturing.

Prior to starting at nTopology, he was in academia as an Assistant Professor in the Department of Aeronautics and Astronautics at the US Air Force Institute of Technology.

Sunil Acharya, PhD, Lead Applications Engineer, ANSYS

Dr. Sunil Acharya is an engineering simulation expert with 21 years of industry experience in simulation-based techniques for product design and process modeling. As a Lead Application Engineer for the ANSYS Customer Excellence (ACE) Team, Sunil’s primary areas of expertise is in materials and multi-physics modeling. Sunil is a mechanical engineer (IIT, Bombay) with a PhD (Polymer Engineering) and MS (Biomedical Engineering) from the University of Akron. Sunil is a member of the NAFEMS Manufacturing Simulations Working Group and the Digital Twin Consortium.

Maiki Vlahinos, Senior Application Engineer, nTopology

His primary focus is in the Aerospace and Defense industries. Vlahinos has nearly a decade of CAE expertise in CAD, FEA and CFD.

Walter Schwarz, PhD, Principal Application Engineer, ANSYS

Dr. Walter Schwarz is an engineering simulation expert with over 30 years of experience in the areas of flow modeling, heat transfer, and turbulence who currently is a Principal Application Engineer for the ANSYS Customer Excellence (ACE) Team. His application expertise covers all areas of aerospace & defense applications, power generation (fossil, nuclear, solar, wind), contaminant & pollutant dispersion, external airflow around buildings, indoor environmental modeling (HVAC), and data center cooling. Dr. Schwarz received his PhD degree in Mechanical Engineering from Stanford University and prior to joining Fluent Inc. in 1996, Dr. Schwarz had worked at Westinghouse in the nuclear industry and had also been an assistant professor of mechanical engineering at Stevens Institute of Technology.

Thomas Spirka, PhD, Senior Applications Engineer, Synopsys

Dr. Thomas Spirka a Senior Applications Engineer the Simpleware Group at Synopsys, working closely with engineers and researchers to solve problems through service projects, technical support and training. Through his current and previous positions, Thomas has acquired over 10 years of experience in working with FEA and CFD models based on 3D image data. Thomas completed his doctorate in Biomedical Engineering at Cleveland State University.