How do you determine the minimum Geometric Magnification to use for Digital Radiography Imaging?

Before we answer this question, we need to answer the following two questions.

- What is the physical size of the anomaly or feature you are trying to detect?

- What is the basic spatial resolution (SRb) of the detector you are using?

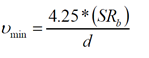

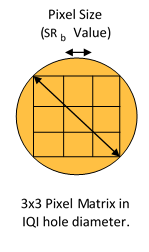

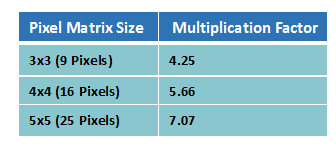

With the answer to these two questions we can calculate the minimum geometric magnification. Industry requirements typically specify a minimum of a 3×3 pixel matrix within the required anomaly or feature however some applications may specify a 4×4 or 5×5 pixel matrix.

Example: I’m looking to detect a 0.010” porosity in a weld, or I’m required to see a 1T penetrameter hole which is 0.010” in diameter. My Detector has a pixel pitch of 0.005” (127um) and an SRb of 0.0065 (165um).

V min = Minimum Geometric Magnification

SR b = Effective Pixel Pitch as measured per ASTM E2597

d = IQI hole Diameter and/or minimum defect size.

If known defect standards are available, it is recommended that one establishes the minimum pixel matrix required for the smallest defect size required to be detected. This should be accomplished by imaging the defect standard. Once the minimum pixel matrix is identified, then a correlation can be made to the representative pixel matrix that should be required for the penetrameter hole which may be a different size than the minimum defect.