Dual Tube CT Systems Offer Incredible Versatility

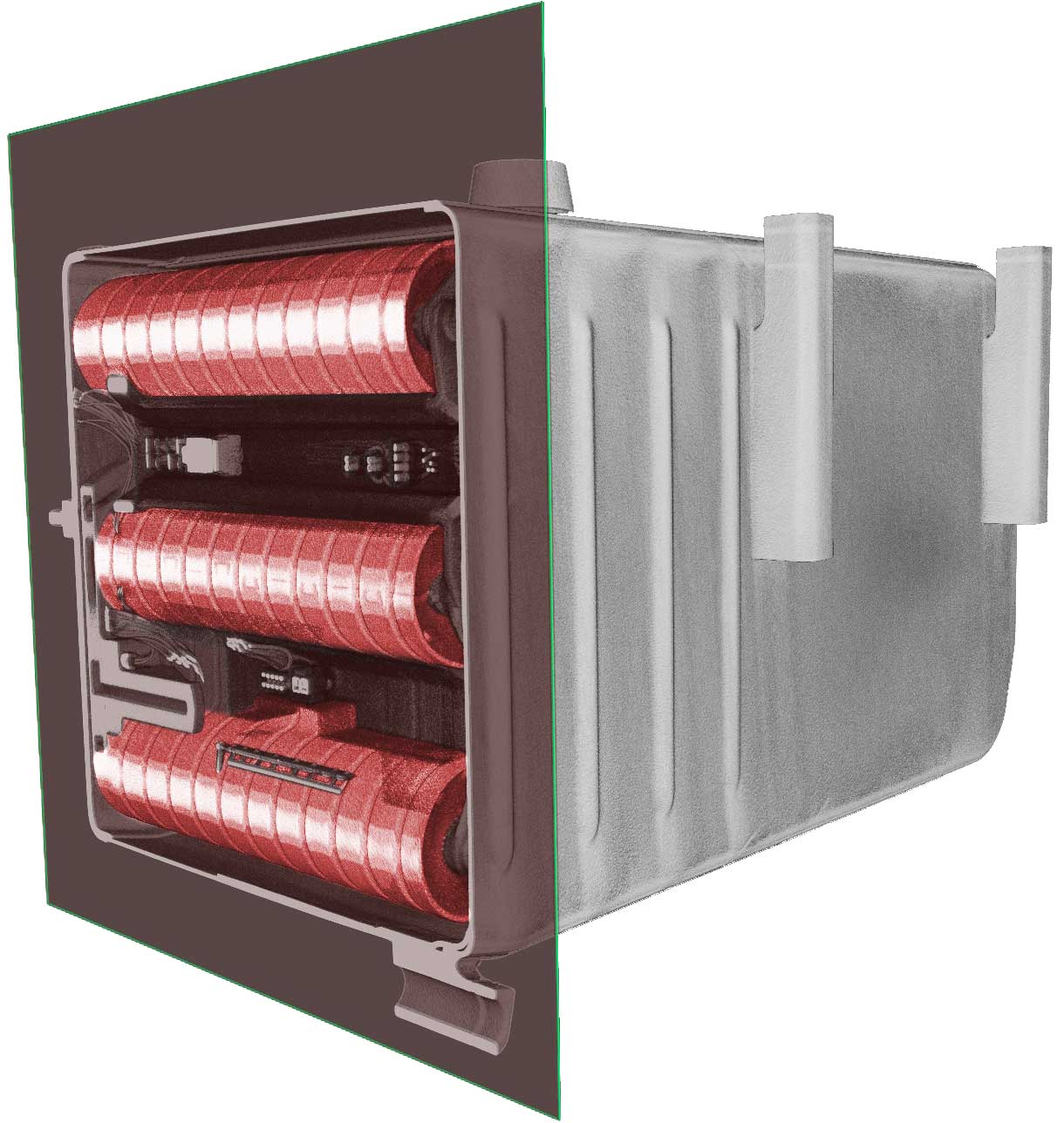

A recent and growing trend in the Industrial X-ray and Computed Tomography (CT) marketplace is a Dual Tube X-ray/CT System; a system which integrates both a Microfocus and Minifocus tube in the same cabinet. Dual Tube systems can scan a broader variety of products, ranging from small parts requiring high resolution all the way up to large, high-density samples. This can be a significant advantage for manufacturers who offer/integrate a wide variety of products, Universities/Research Organizations with ever-changing projects, or other similar companies.

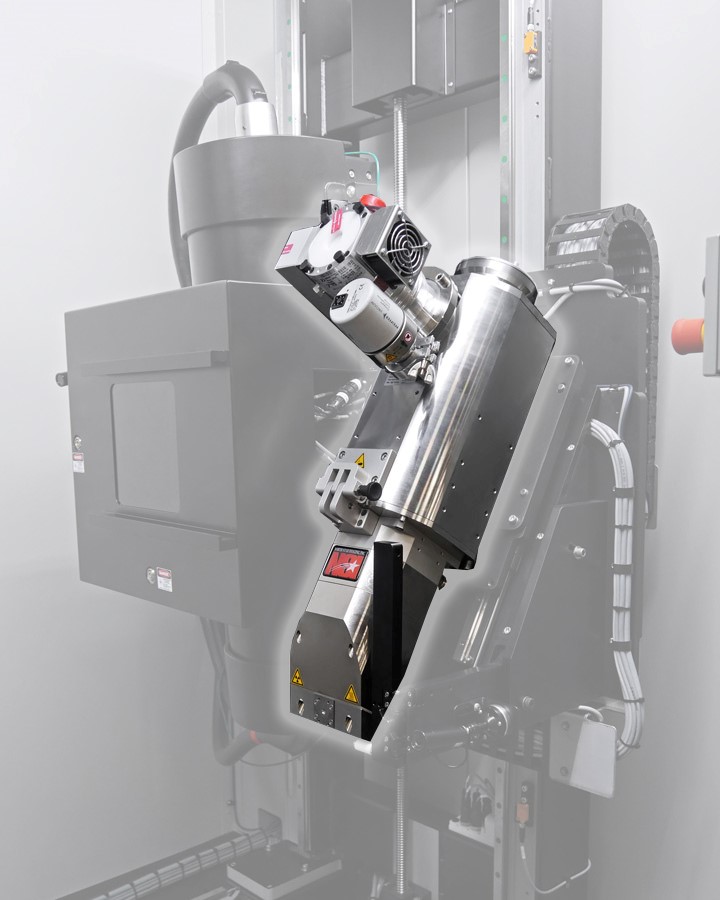

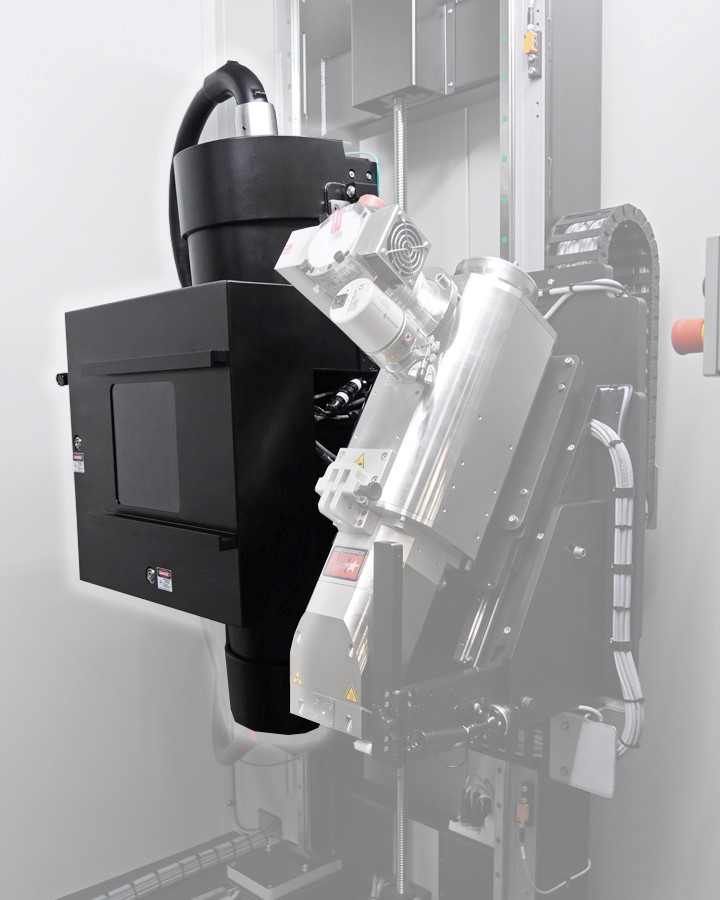

Historically, the two most common X-ray tubes in the industrial X-ray/CT industry are the 225kV Microfocus and the 450kV Minifocus. Both have their advantages and disadvantages depending on the sample and scanning requirements of the customer.

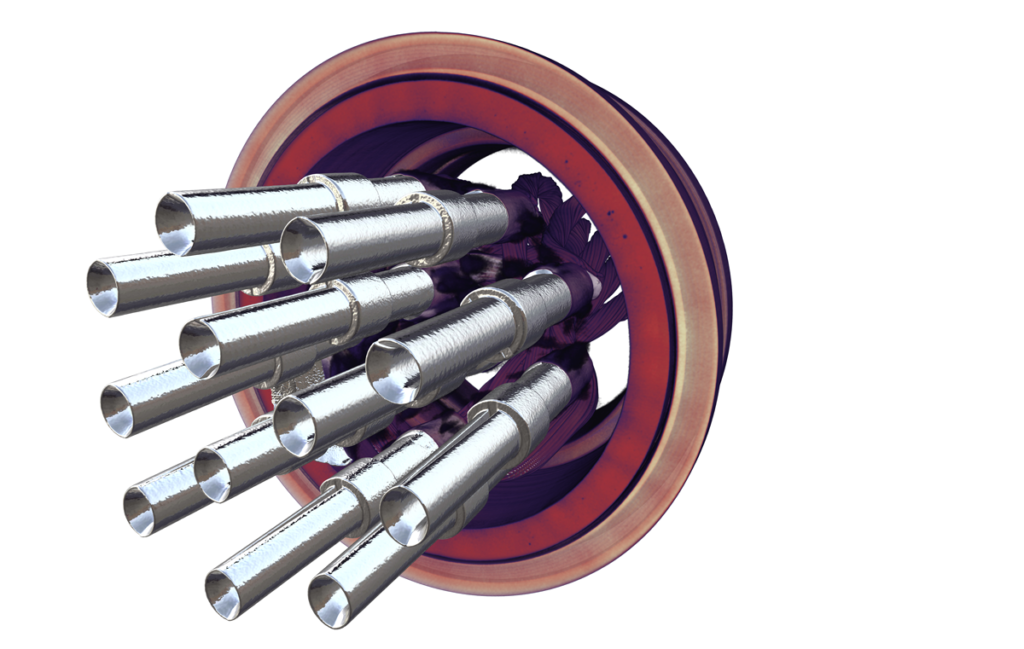

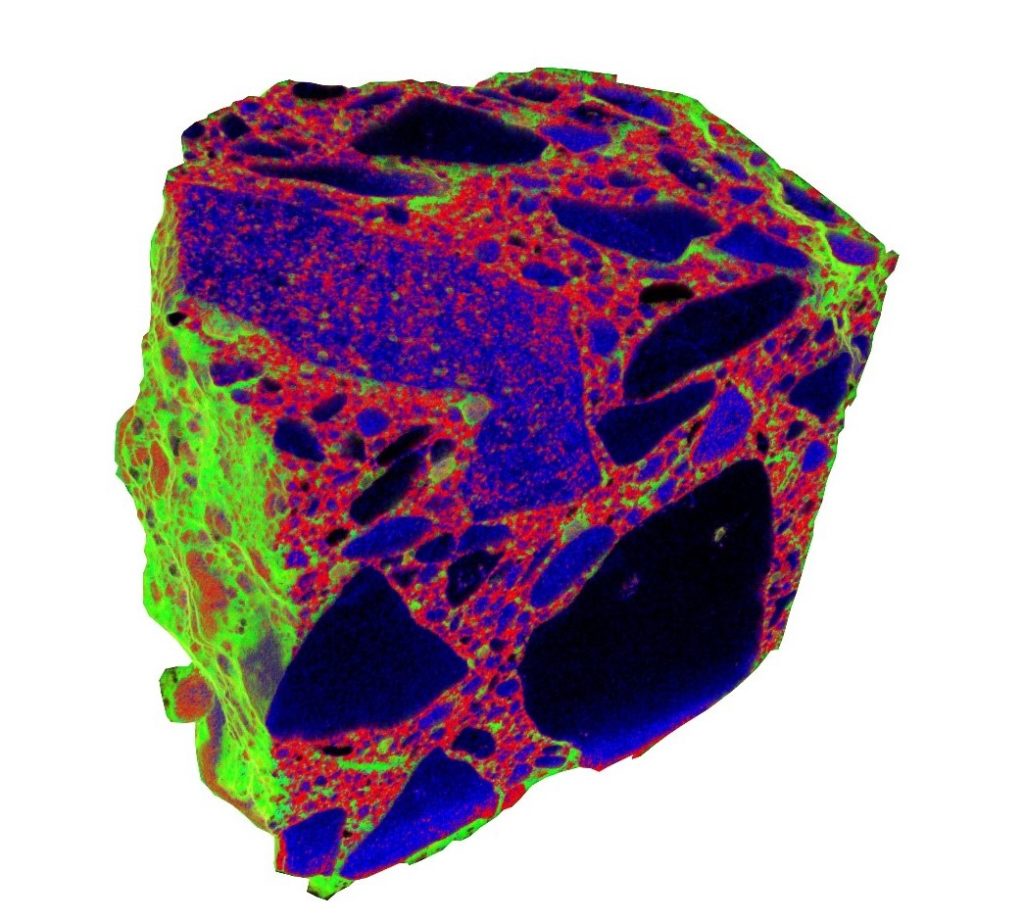

The 225kV Microfocus tube is great for plastics, composites, aluminum or even steel if it is under a couple inches thick. A Microfocus tube allows technicians to use high geometric magnification and can even achieve scan resolutions better than 5 microns with the right technique and optimum products. While this high resolution is great for these samples, a 225kV Minifocus tube simply does not have enough power to penetrate some of the higher density products.

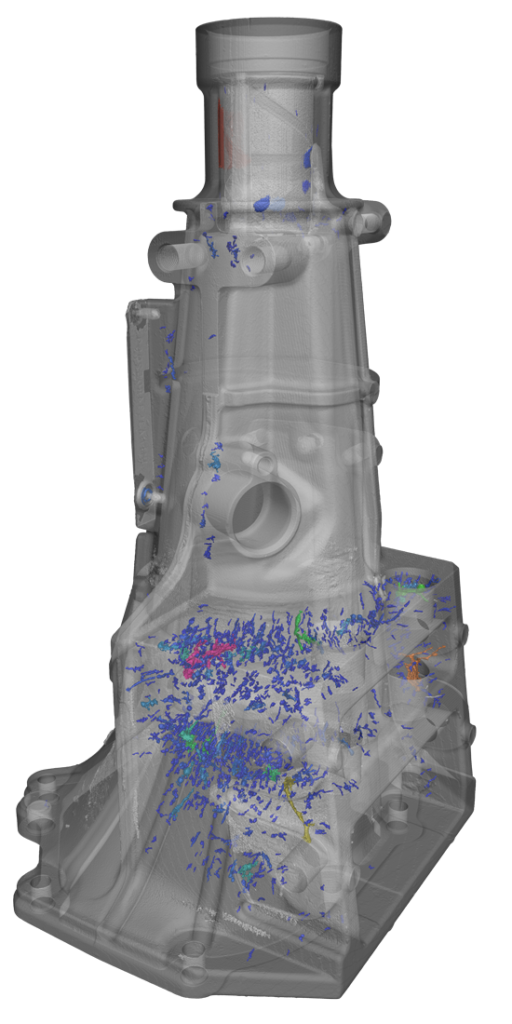

The 450kV Minifocus tube shines with bulkier or high-density products like larger steel and aluminum castings, core samples, large assemblies, etc. Due to the geometric unsharpness limits of the larger Minifocus focal spot, roughly 2x magnification, an optimum technique with a 200um panel yields about a 100um scan resolution (or around 50um if NSI’s subpiX technology is used). While the additional power of 450kV Minifocus tube is required for the high-density products, it may not provide the fine detail required on some of the smaller, lower density products.

Therefore, how does a customer decide what is the best fit for them? In the past for example, an aerospace or automotive customer who needed to scan products ranging from a small electrical connector all the way up to an engine casting needed to look at their product line and decide which one was the most important at the time. They would then configure and acquire an X-ray/CT system to meet the specific needs of that product, leaving them searching to find a different solution for the remaining products. That may mean dealing with non-optimized scans, or buying an additional system, or finding a different way to inspect those products all together.

Universities or Research Organizations for example may have received a grant for a current project with specific scanning requirements. In the past, if they purchased a single tube system, there is a risk that the next project they encounter will have different scanning requirements and force them to reapply for more grant money or not deliver the best results possible.

Now, with a Dual Tube X-ray/CT system, a customer like this can simply integrate both a 225kV Microfocus tube and a 450kV Minifocus tube in a single cabinet to meet the individual scanning requirements of their entire product line. Universities and Research Organizations can now install a single machine which will adapt to their ever-changing needs for years to come.

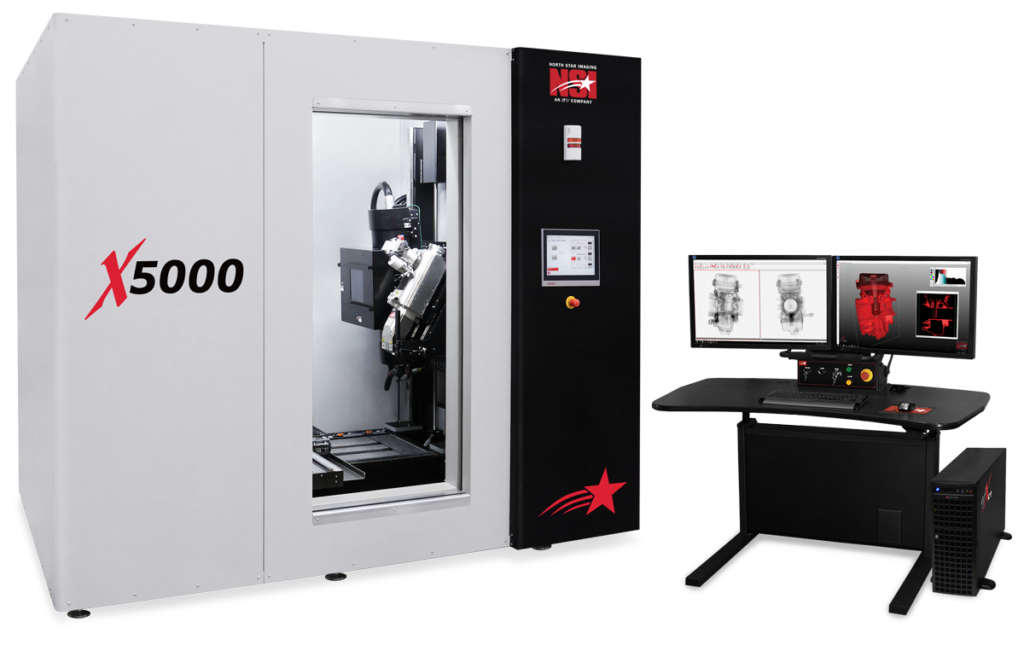

North Star Imaging offers a Dual Tube configuration in both their X5000 and X7000 turn-key systems as well as their X5500 and X7500 stand-alone manipulator products.