Beam Hardening – What is it and how to reduce it

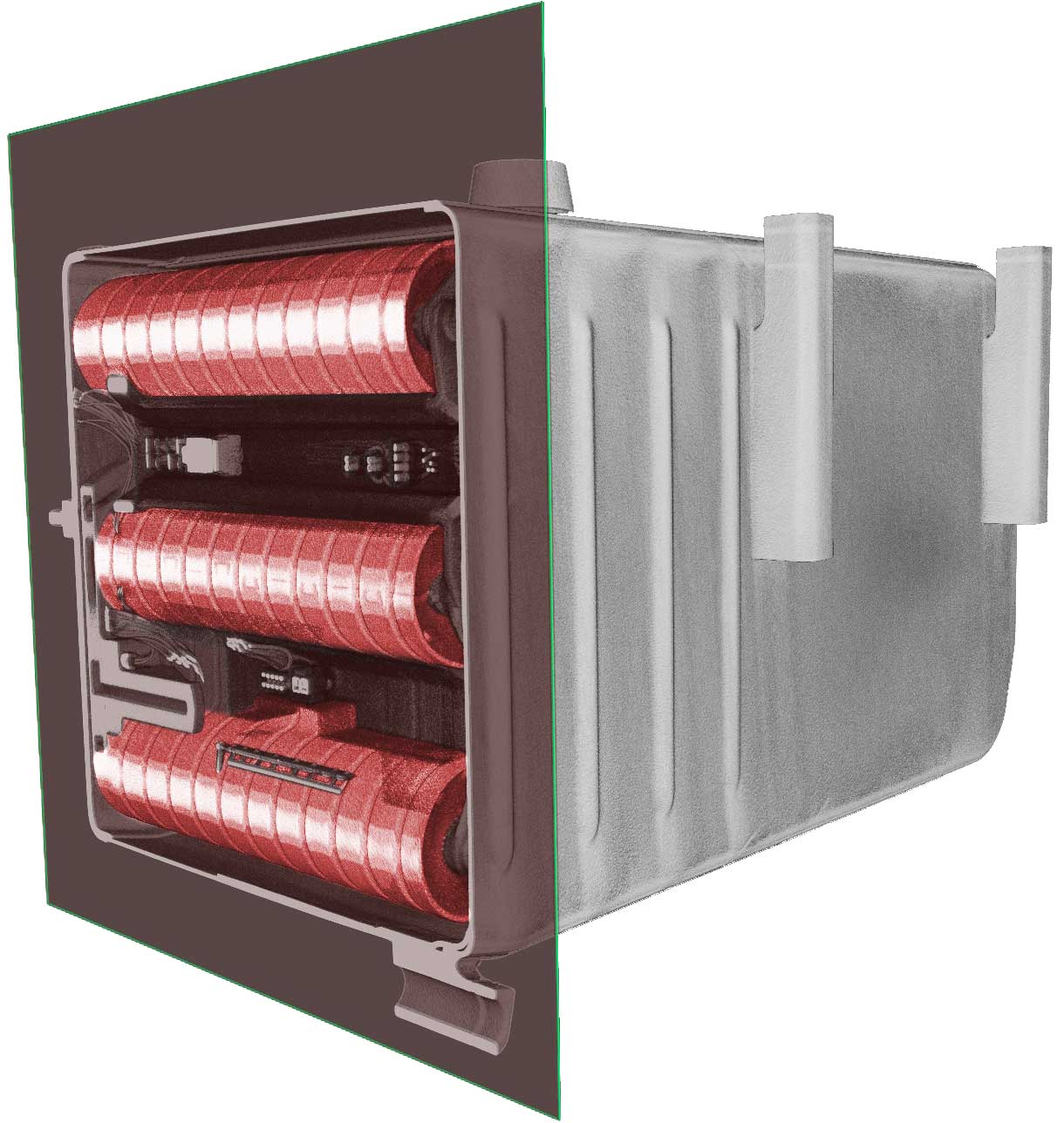

X-ray micro computed tomography (micro-CT) is a powerful tool for material characterization as it can non-destructively and non-invasively image the internal structure of an object. This enables the wide range of characterization and inspection applications in the areas of biomedical, aerospace, automotive, and many more.With the recent development of novel reconstruction algorithms, we can not only image the object in 3D but also record how its structure is varying over a period (i.e. 4D imaging, as a software add-on offered by NSI).

In a typical computed tomography (CT) set-up, a micro-CT image is generated by rotating the sample in very small steps around a single axis of rotation while taking a series of 2D radiographs. Afterwards, a 3D image can be numerically reconstructed from these radiographies using reconstruction algorithms, such as filtered back projection algorithm, and can be saved either as a series of section images or a volume file.

The physical basis of micro-CT is that material attenuates the X-ray passing through it. The attenuation rate depends on X-ray energy and composition of the object. When a suitable range of energy is used so that the attenuation is mainly contributed by the photoelectric effect, the intensity of the transmitted X-rays is related to the incident X-ray intensity by:

where I0 is the intensity of the unattenuated X‑ray beam, and I is the beam’s intensity after it traverses a thickness of material x characterized by a linear attenuation coefficient µ . The term µ / p is the mass attenuation coefficient (cm-2 g-1) of the object and the equation can be rewritten as:

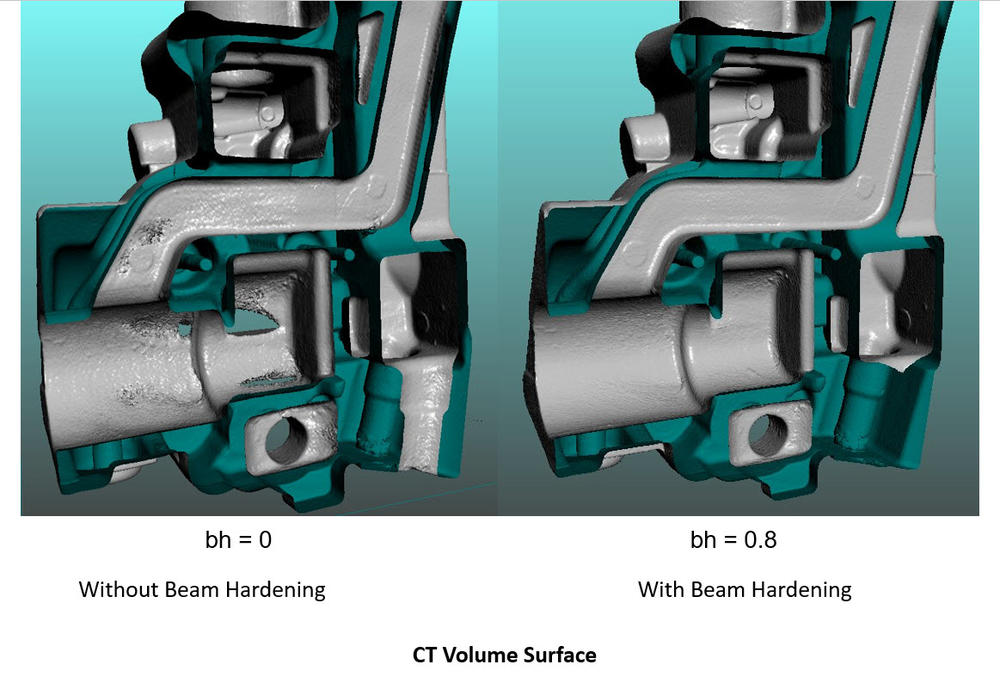

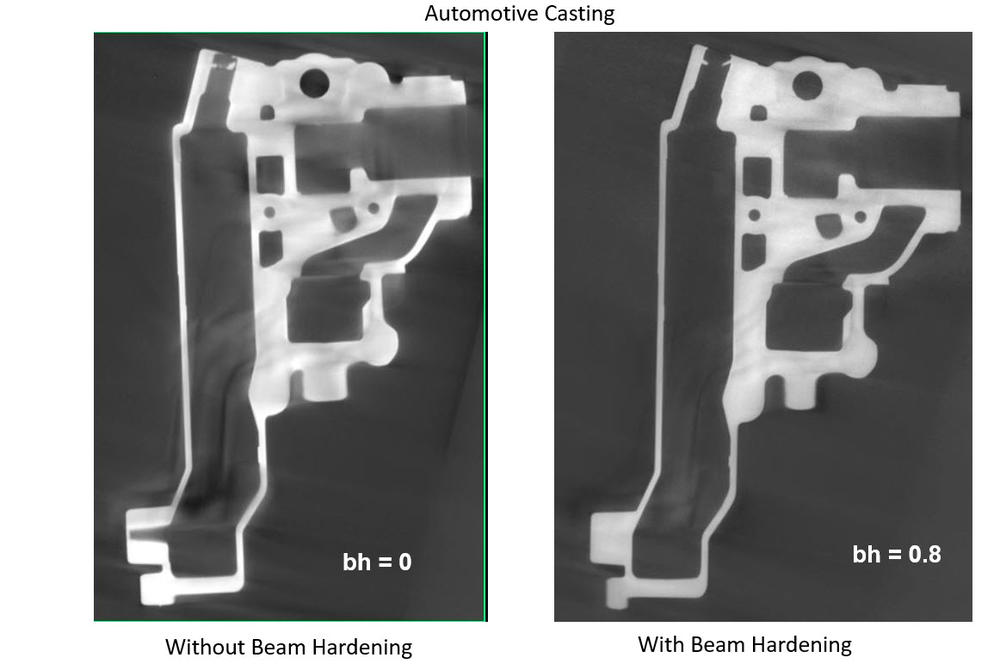

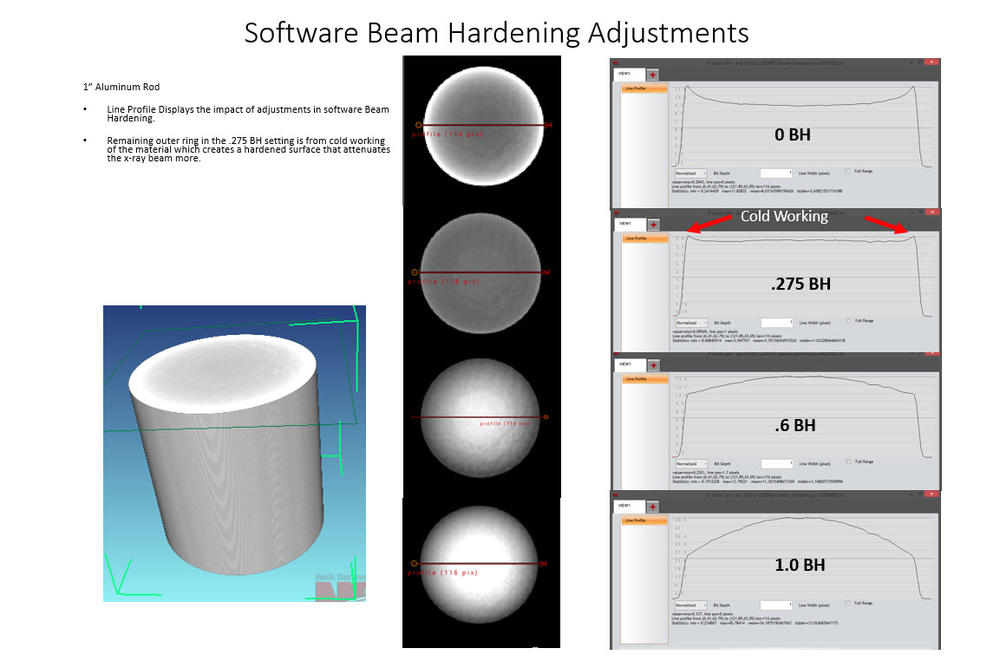

The mass attenuation coefficient is a function of the incident X-ray photon energy, density and composition of the material. However, the Beer’s law (as shown in Equation 1) is only almost true when imaging with monochromatic beam (single energy X-ray). In reality, laboratory X-ray systems are normally employing a polychromatic beam (a range of energy spectrum), and these various components of the energy spectrum are not attenuated uniformly when passing through an object. The lower energy component of X-ray spectrum is more easily attenuated or even completely adsorbed when traveling through a dense part. And if we reconstruct the image assuming that the beam attenuation is linear, then the edge of the object in the reconstructed volume will have brighter voxels even if the object is composed with homogeneous material. This artefact is called beam-hardening, or cupping artefact.

The most obvious problem from beam hardening is that it gives false information about the sample’s composition/density. It also negatively influences results when trying to separate materials by intensity difference (i.e. through global thresholding). Therefore, various methods have been developed to reduce or correct beam hardening from micro-CT scans, some of those common methods or strategies are listed as following:

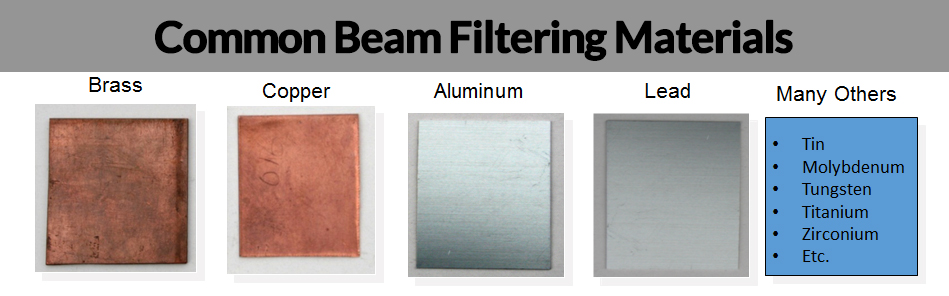

1. Pre-harden the beam

A thin metal plate can be placed between the X-ray source and the object to reduce the amount of “soft” X-ray (therefore there are higher percentage of “hard” X-ray in the beam, i.e. the beam has been hardened). Using this method, the reconstructed image will suffer less from beam hardening artefact as less low energy X-ray has been preferentially attenuated.

2. Filter at the sample: Tubing or liquid bath surrounding the part.

Similar to the previous method, and if it is feasible, we can put the entire sample into a metal tube or a liquid bath so that the surrounding metal or liquid can be used as filtering material to not only reduce soft X-ray from the source but also reduce the scattering effect.

3. Post correction and advanced computation/simulation methods

Beam hardening can also be corrected/reduced during reconstruction. NSI’s reconstruction software allow a series of sample images to be computed with a selection of beam hardening correction parameters, so you can select one with the most desired result for the full reconstruction. In a more advanced approach, beam hardening can also be reduced by simulating the attenuation process when an X-ray beam (with known properties) traverses through the sample.

Hopefully this brief introduction gives you an idea of beam hardening and how to reduce it. Remember, correct filtering is very important and can greatly improve the overall quality of a scan.