2D and 3D Comparison to In-situ Process Monitoring

In- Situ Monitoring technology continues to make advancements in numerous Additive Manufacturing (AM) processes. A great way to initially evaluate and then improve upon the effectiveness of the process is by understanding the correlation between the in-situ monitoring of the AM part and the results from the Computed Tomography (CT) scan of the part.

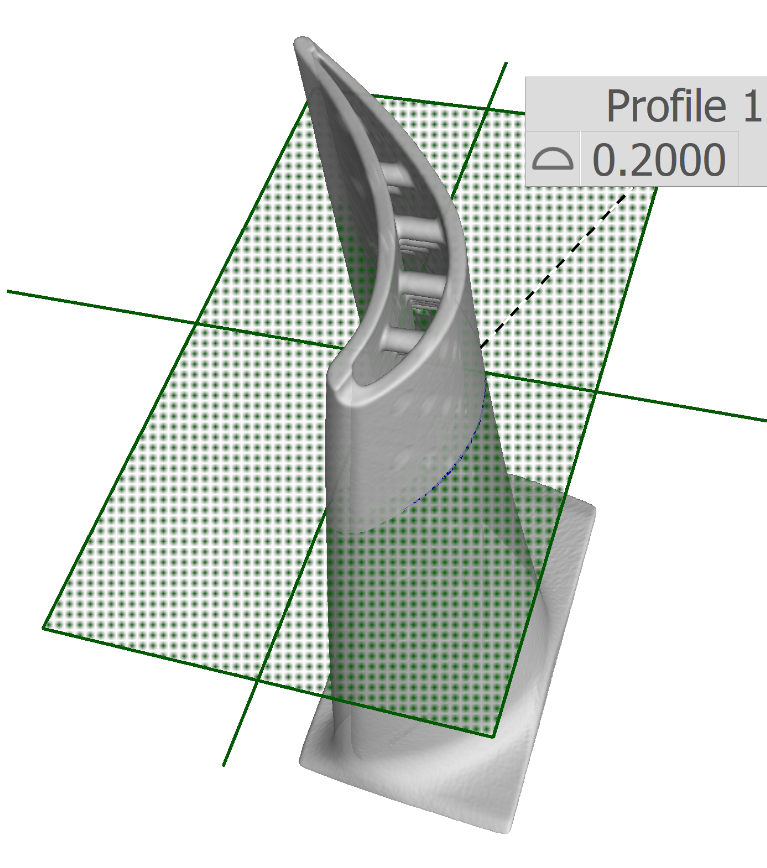

Layer by layer data from the in-situ detectors can be spatially correlated to CT scan data to provide tweaking of the process to prove prediction models of discontinuities forming. Basically, if in-situ monitoring of the melt pool predicts a porosity of a specific size is likely to occur at a given location within the build, there should be a direct correlation for that indication within the CT scan.

Once this correlation has been optimized, CT can be used to validate final in-situ programs and used to perform process control monitoring over time.