Manufacturing

2D & 3D CT X-Ray Scanning for Manufacturing

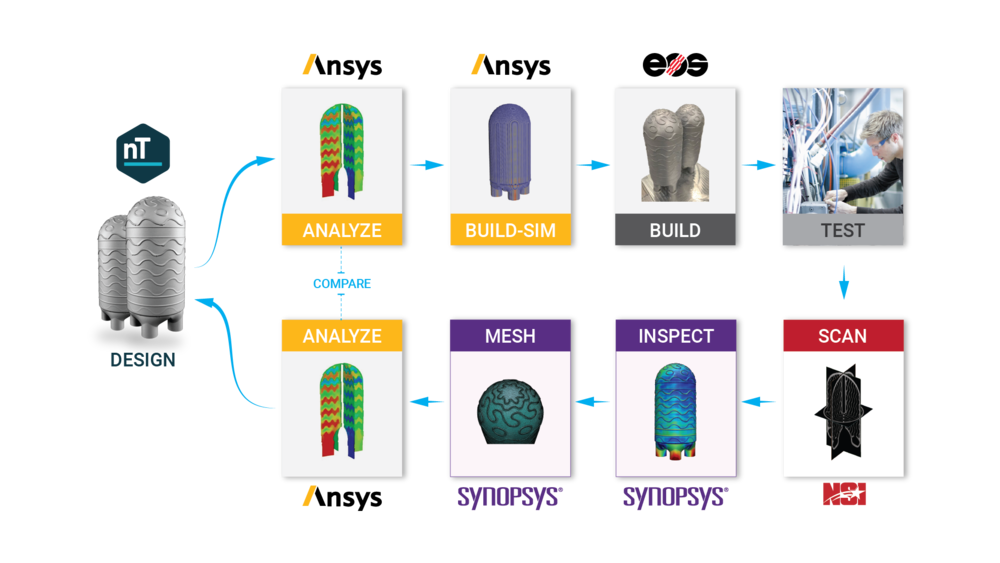

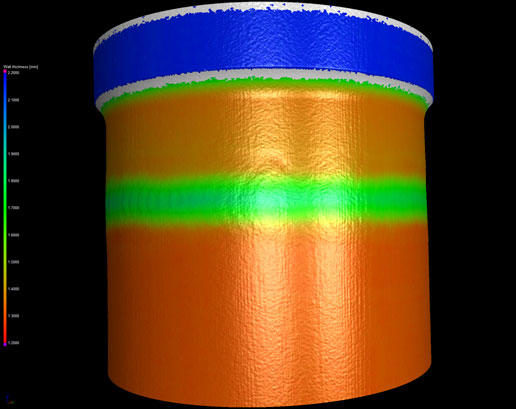

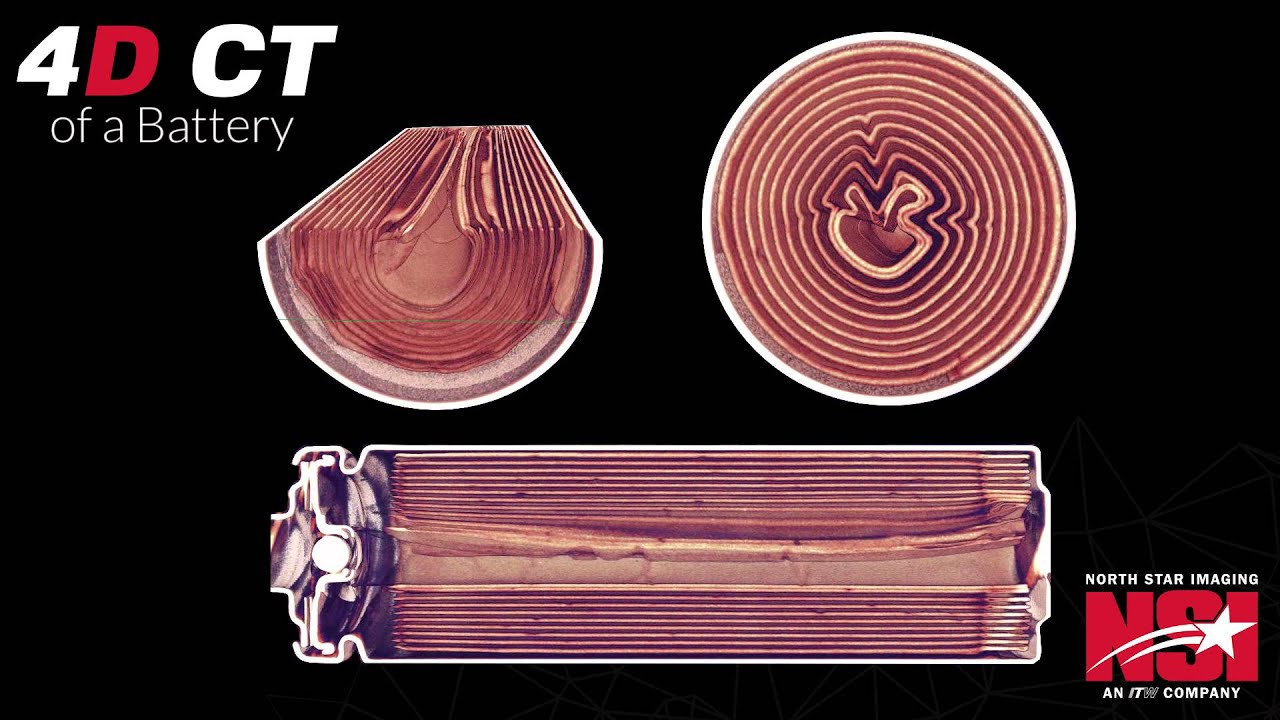

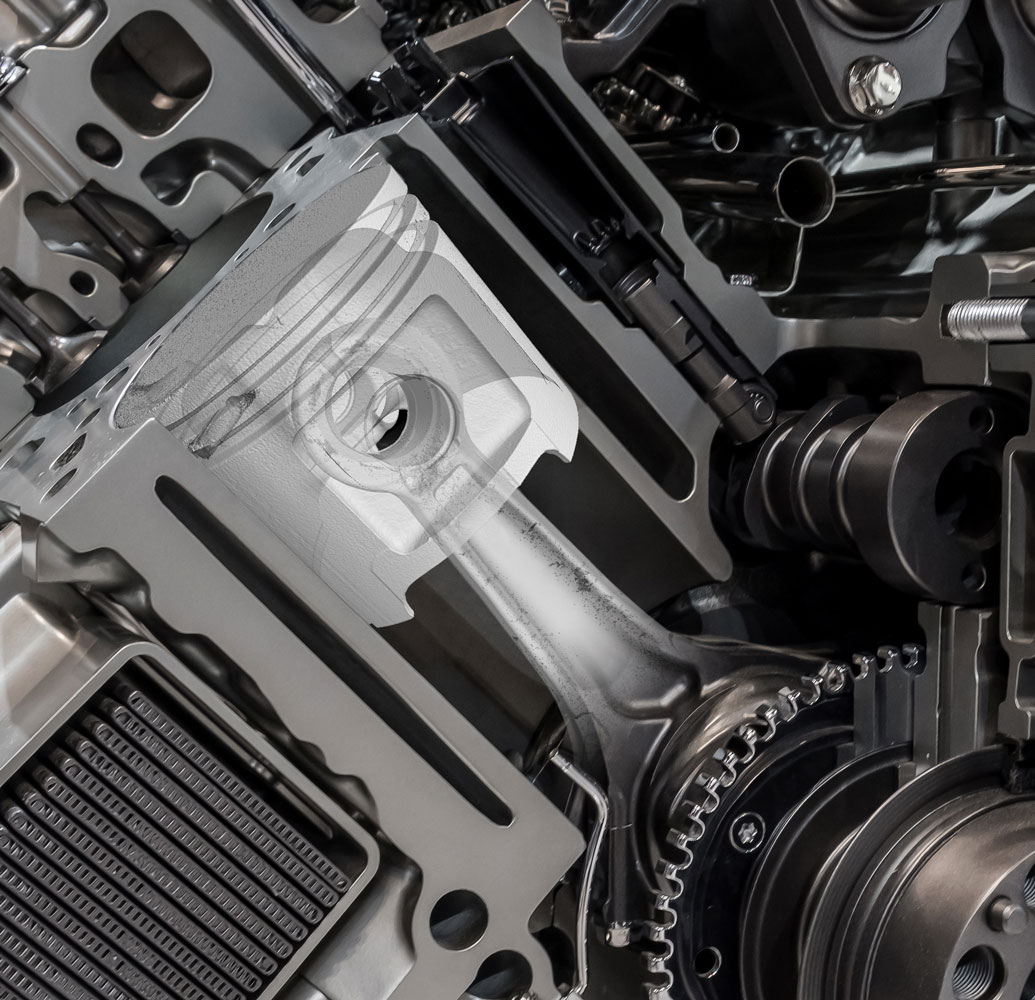

Nearly every product available today has gone through many stages of manufacturing, including integrating components from many different companies along the way. Whether you are providing raw materials, supplying as an OEM or you are bringing the product to market; everyone is responsible for delivering a quality product. NSI’s versatile X-ray and Computed Tomography Systems can help ensure material quality, help engineer a better design through research and development or even assist with failure analysis should a problem arise. Our team is ready to help your team take a deeper look inside your most quality-critical components, to know what’s working and what isn’t.

See more, know more.

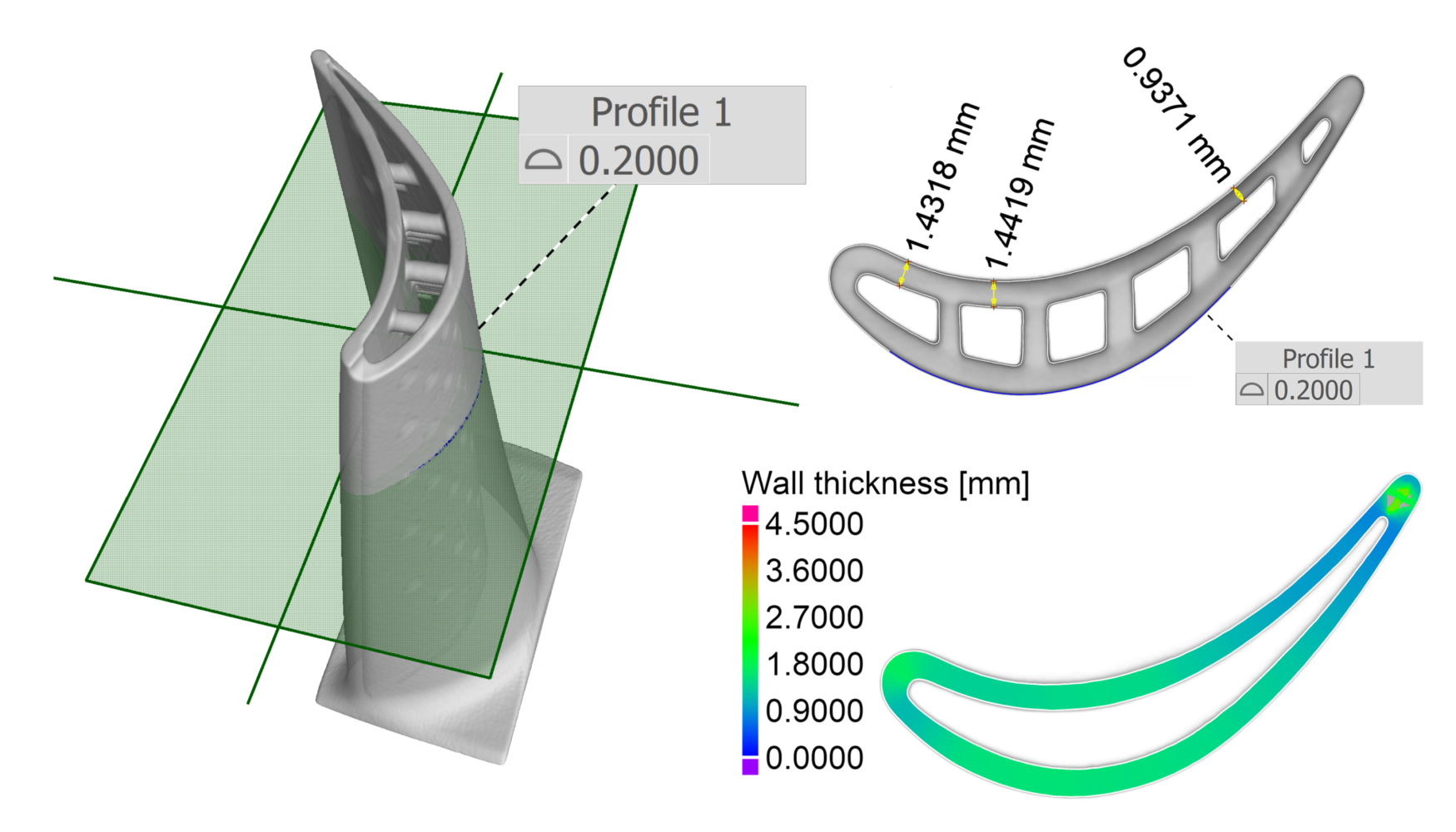

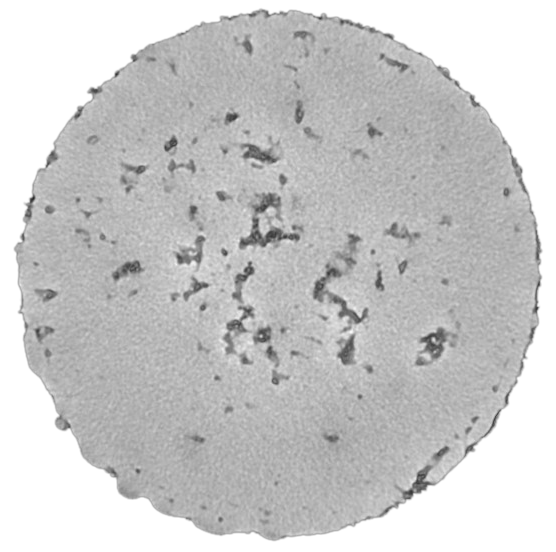

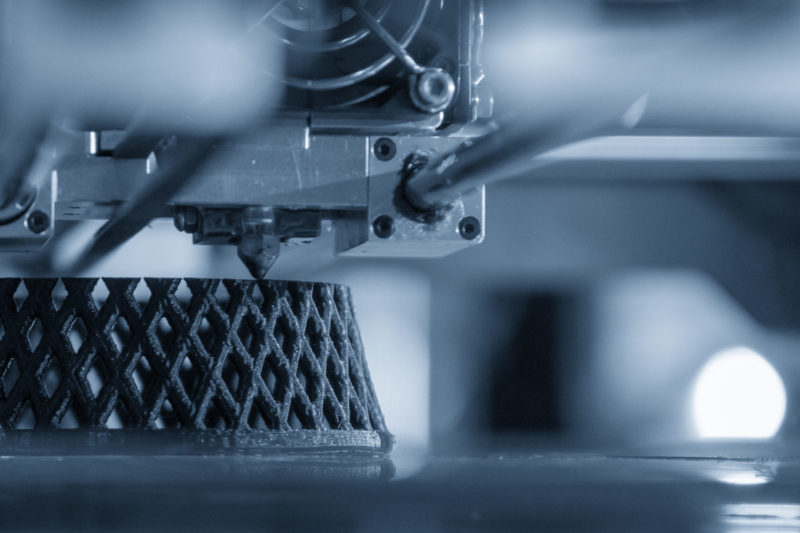

The global nature of product development these days means almost every product today has gone through many stages of manufacturing. Whether you’re supplying raw materials, working as an OEM or bringing products to market, our 2D and 3D Computed Tomography (CT) X-ray inspection technology will help you ensure material quality and engineer better designs with data-driven insight you used to think was impossible. You’ll get a better picture from every angle:

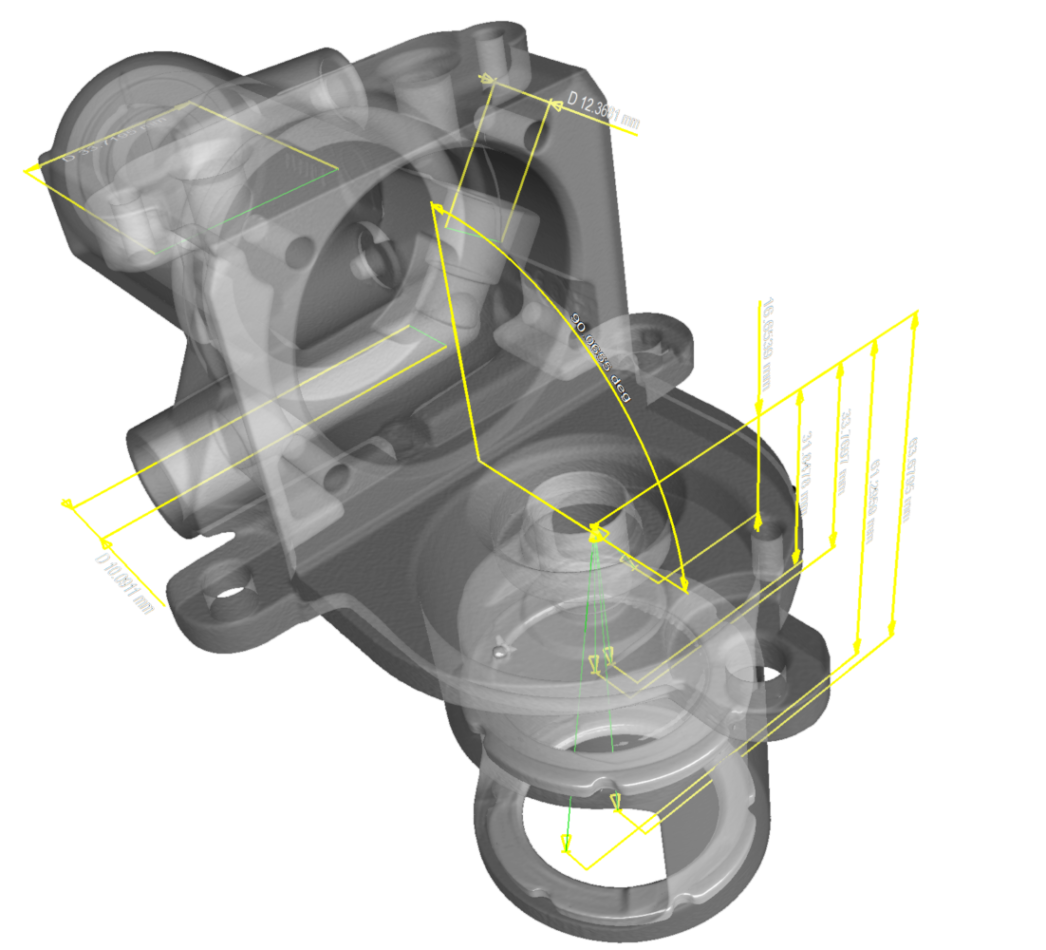

- CT scan of fuel injector features to improve reliability and longevity

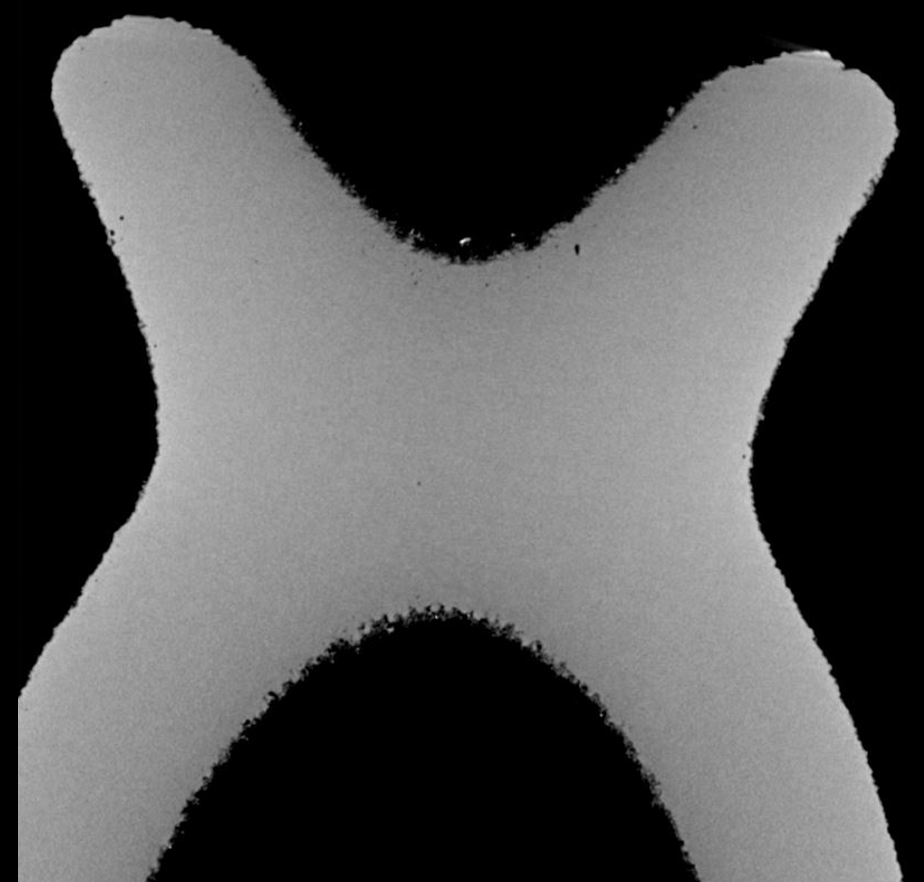

- Check for foreign object debris (FOB) that’s detrimental to electric motor performance

- 3D X-ray scans to model components for identical 3D printed parts

- And much more