Using X-ray Computed Tomography for Dimensional Metrology

X-ray computed tomography (CT) has successfully entered the field of coordinate metrology as an innovative and flexible non-contact measurement technology for performing dimensional measurements on industrial parts. It provides unique advantages compared to conventional tactile and optical coordinate measuring machines (CMMs), giving the ability to perform nondestructive measurement tasks that are often not possible with any other measurement technology.

In industrial production, the requirements of dimensional quality control are becoming more complex. For example, new manufacturing technologies such as Additive Manufacturing produce complex and non-accessible internal features. Many times it is not possible to inspect these products with the traditional measurement technologies and without cutting or sectioning the component. X-ray CT offers unique capabilities of performing a wide variety of measurement tasks, even on non-accessible features and in a nondestructive way.

The field of application of CT is extremely wide and includes a high number of markets as summarized in Figure 1.

One of the key aspects of the use of CT in the modern industry is the possibility to perform quantitative analyses on a lot of different applications and at several stages of the different products cycles enabling the evaluation of conformity to product specifications, and the optimization of products and manufacturing processes.

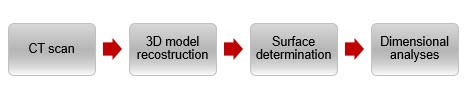

CT measurement process chain

The X-ray CT working principle is based on X-rays propagation through the workpiece and the acquisition of several radiographic projections (X-rays radiographs) containing information on the X-rays attenuation through the object. Dedicated software, such as NSI efX-CT is then used to reconstruct a 3D model of the scanned part characterizing its whole internal and external features from the acquired projections.

After performing the “surface determination” step in which the surface of the object is identified, the dimensional analyses on the 3D CT model can be made. Figure 2 shows the main steps of X-ray CT measurement process chain.

CT metrological applications

With CT it is possible to perform high accuracy holistic measurements of the entire workpiece without any form of contact and need to cut or destroy the part. And even more, all of this can be done through combining material inspection and dimensional quality control in one single scan.

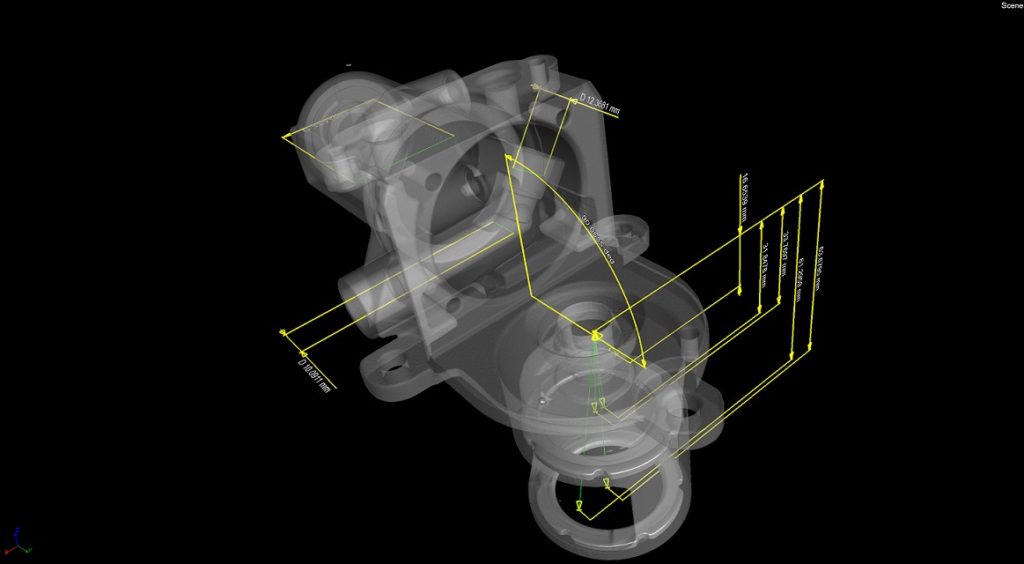

CT capabilities include the ability to perform tolerances verification, i.e. evaluate the conformance or non-conformance of products to specifications, on both internal and external features of the part. An example of this is given in Figure 3.

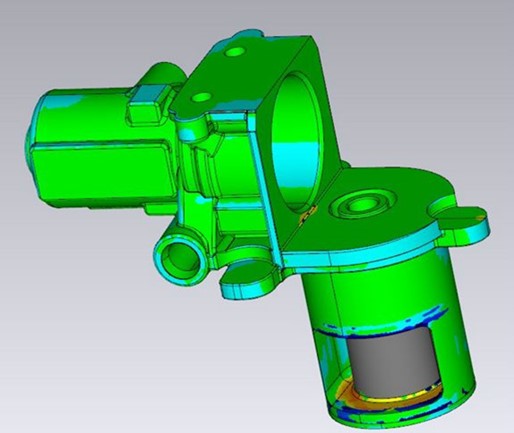

With X-ray CT it is also possible to perform nominal/actual comparisons in which the volumetric model of the actual part is registered and compared to its nominal model. For example, in the so called “CAD comparison” the actual 3D model of the scanned part is compared to the CAD model of the component, enabling to obtain quantitative information on the local deviations between the actual part and the CAD model.

In Figure 4, the colored map shows the local deviations between the scanned part and its CAD model. Each color represents a different range of deviation.

It is also possible to compare CT scans. This can be useful to analyze the same component scanned at different stages of its life cycle, or to compare actual components obtained with different process parameters.

Reverse engineering is one of the several capabilities that CT provides. Thanks to the acquisition of dense volumetric information, CT is a powerful tool for the reverse engineering of products. It is possible to extract the STL file of the component or the point cloud from the CT volume.

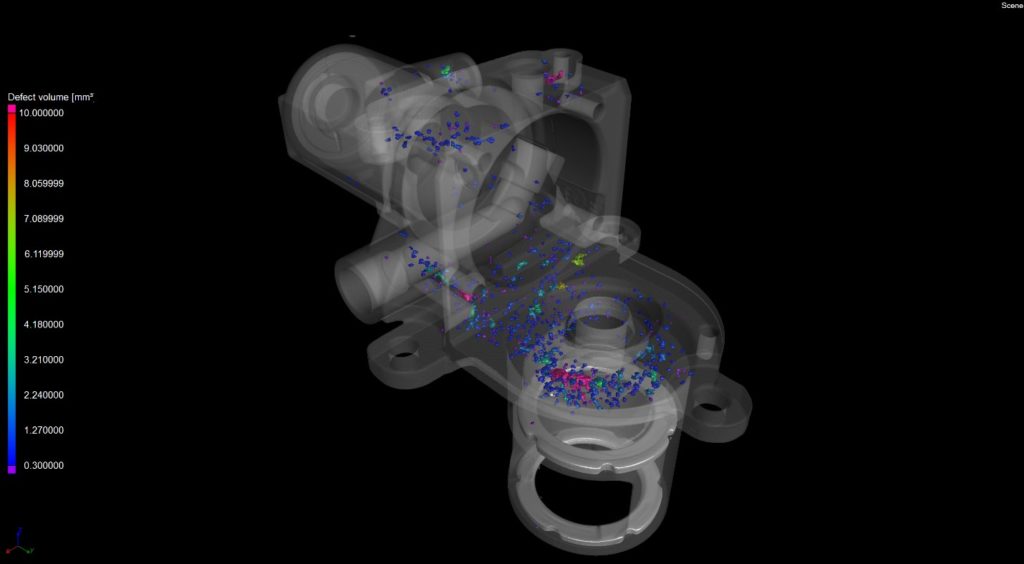

CT enables performing other kinds of quantitative analyses besides the examples given above, including wall thickness analyses, and porosity analyses.

Figure 5 shows an example of porosity analysis on a die casting component. Compared to conventional methods that typically detect the overall porosity of the component or to destructive testing on specific sections of the component, CT offers the unique capabilities to not only detect the different porosity but also to locate the porosity in the 3D model of the part and to provide information on the different porosity volumes.

CT advantages over conventional measurement technologies

An overview of the main advantages that CT provides over traditional measuring techniques is given in the following:

- Holistic measurements of the components and materials inspection in a single scan

- Dimensional analysis on internal or non-accessible features in a non-destructive way

- Measurements on deformable components

- Analysis of assemblies (i.e. components in the assembled state)

- Ability to perform measurements regardless of surface color, reflectivity and slope

- Acquisition of dense volumetric information in a short amount of time

- Reverse engineering

X-ray CT measurements are not limited by the probe dimensions as it happens for tactile CMMs, because no mechanical contact with the component is involved. At the same time, it is not needed any mechanical or optical accessibility to the feature of interest as instead it is required for respectively tactile probes and optical sensors. Fundamental factors for CT include the achievable geometrical magnification which depends on the part size and geometry, the part material and thickness.

CT measurements, moreover, can be performed on deformable components that typically are not possible to inspect with tactile CMMs due to the mechanical contact that is always involved. CT furthermore offers advantages also over optical sensors such as the possibility to perform measurements regardless of surfaces shape, color and reflectivity. This can be a serious issue for optical systems.

CT also allows to analyze components in the assembled state. This task is usually difficult to perform with traditional measuring instruments. Furthermore, it allows to perform reverse engineering of products in a short amount of time and to acquire much denser information than what it would be possible in the same amount of time with e.g. a conventional tactile CMM.

Conclusions

X-ray CT is a valuable and flexible multi-purpose measurement technology that offers unique advantages. Its fields of application are extremely wide and involve several markets such as aerospace, automotive, castings, traditional manufacturing, Additive Manufacturing etc. With CT it is possible to perform, high accuracy measuring tasks that are not possible with any other measurement technology, including the analysis of internal complex geometries in a nondestructive way.