Enhance Quality Control on Life-Critical Devices

Computed Tomography for Medical Devices

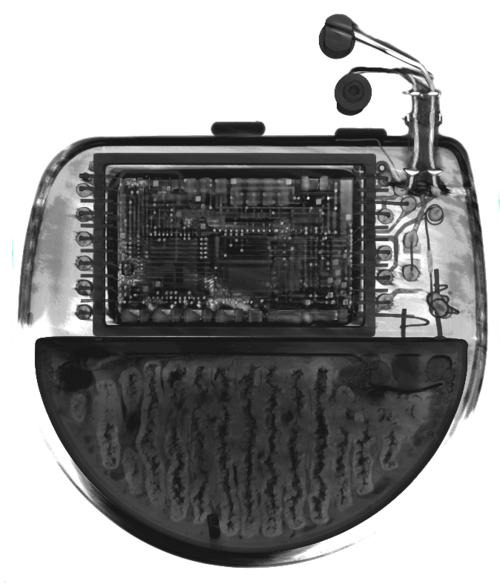

Pacemakers and other implantable medical devices must be free of even minor defects. Being able to verify the performance of a medical device, as well as ensure that it meets the required quality standards and regulations, is of paramount importance in order to eliminate the risk to the patient.

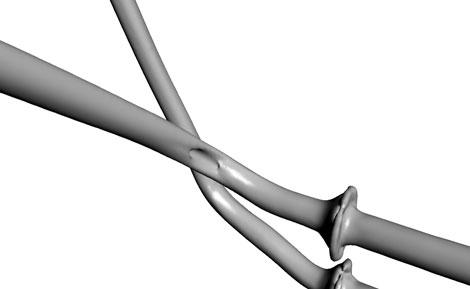

When imaging a pacemaker, most medical manufacturers are looking for possible defects in the battery, circuitry and the laser welded casing that holds and protects the electronics. Because access to the circuitry of implantable devices is impeded by the packaging of the device, and because the packaging may have influenced the failure, nondestructive testing techniques must be used extensively in R&D, product development as well as final production.

Medical device manufacturers must adhere to the strictest quality requirements and nondestructively testing these parts can not only save time and money but ultimately save a life.